Method for detecting polymer content in sodium methacrylate monomer salt by using HPLC (High Performance Liquid Chromatography)

A technology of sodium methacrylate and sodium polyacrylate, applied in the field of analytical chemistry, can solve the problems of no detection method, no sodium methacrylate, etc., and achieve the effects of good repeatability, strong selectivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

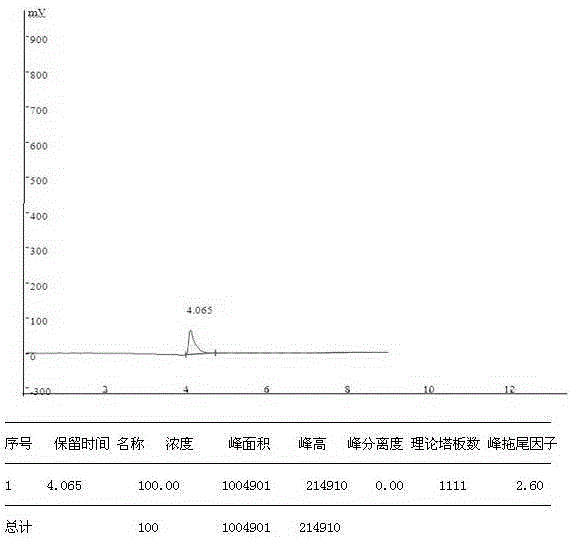

Embodiment 1

[0025] 1. Instruments and conditions

[0026] High performance liquid chromatography: Beijing Innovation Tongheng 3000 high performance liquid chromatography system and workstation

[0027] Chromatographic column: InertexC18, 4.6×250mm, 5μm

[0028] Mobile phase: methanol-water (45:55)

[0029] Flow rate: 1.0mL / min Column temperature: 30°C

[0030] Detection wavelength: 225nm

[0031] Injection volume: 10 μL.

[0032] 2. Experimental steps

[0033] (1) Preparation of reference substance solution: Weigh 10mg of sodium polyacrylate solid into a small beaker, add 1-2ml of pure methanol solution, stir to completely disperse the sodium polyacrylate solid, then add 35-45ml of water to dissolve it Dissolve and stir evenly, pour the above-mentioned solution into a 100ml volumetric flask, scrub the small beaker several times with a methanol:water ratio of 45:55, and pour the scrubbed solution into a 100ml volumetric flask , until the amount of the solution reaches 100ml, take 5.0...

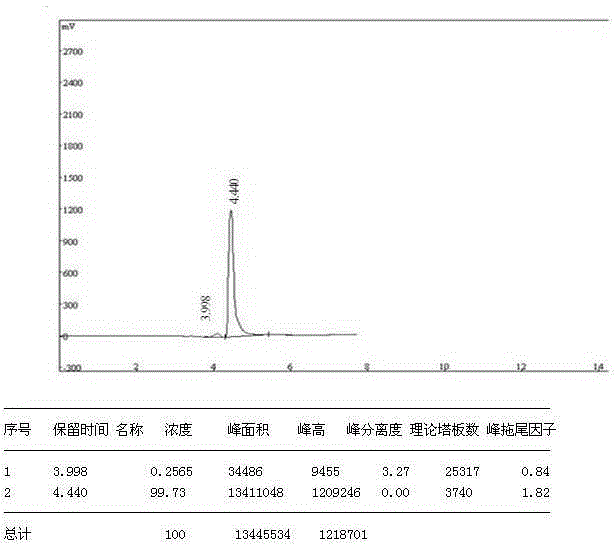

Embodiment 2

[0039] 1. Instruments and conditions

[0040] High performance liquid chromatography: Beijing Innovation Tongheng 3000 high performance liquid chromatography system and workstation

[0041] Chromatographic column: InertexC18, 4.6×250mm, 5μm

[0042] Mobile phase: methanol-water (50:50)

[0043] Flow rate: 0.8mL / min Column temperature: 25°C

[0044] Detection wavelength: 220nm

[0045] Injection volume: 10 μL.

[0046] 2. Experimental steps

[0047] (1) Preparation of reference substance solution: Weigh 10mg of sodium polyacrylate solid into a small beaker, add 1-2ml of pure methanol solution, stir to completely disperse the sodium polyacrylate solid, then add 35-45ml of water to dissolve it Dissolve and stir evenly, pour the above-mentioned solution into a 100ml volumetric flask, scrub the small beaker several times with a methanol:water ratio of 50:50, and pour the scrubbed solution into a 100ml volumetric flask , until the amount of the solution reaches 100ml, take 5.0...

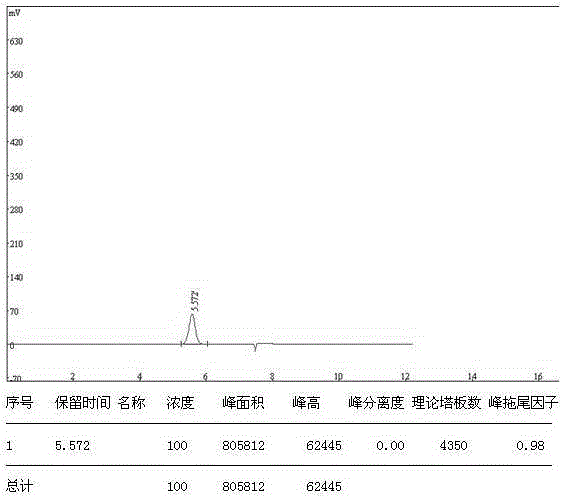

Embodiment 3

[0053] 1. Instruments and conditions

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com