Nano antibacterial bone filling materials and production method thereof

A filling material and nanotechnology, applied in the field of medical materials, can solve the problems of poor antibacterial effect, easy infection of the affected area, low porosity, etc., and achieve the effect of preventing inflammation of the affected area, reducing pain of patients, and increasing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

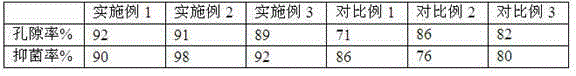

Examples

Embodiment 1

[0016] A nano antibacterial bone filling material, comprising the following raw materials in parts by weight: 30 parts of hydroxyapatite, 5 parts of nano-silver powder, 2 parts of nano-titanium dioxide, 8 parts of glycerin, 10 parts of polyethyl acetate, 20 parts of citronella extract Parts, 2 parts of nano silicon dioxide, 12 parts of epoxy resin.

[0017] The preparation method of the above-mentioned nano antibacterial bone filling material comprises the following steps:

[0018] Step 1, mix hydroxyapatite, nano-silver powder, nano-titanium dioxide, nano-silicon dioxide and epoxy resin, grind to 800 mesh, put it into the reaction kettle, raise the temperature to 2000°C at a constant speed, keep it warm for 5 minutes, and continue to heat up to 2800°C °C to obtain the first mixed solution, wherein the rate of constant temperature rise is 5 °C / min, and the heating time is 0.5 hours;

[0019] Step 2, when the first mixed liquid is cooled to 40°C, add glycerin and citronella ex...

Embodiment 2

[0021] A nano antibacterial bone filling material, comprising the following raw materials in parts by weight: 35 parts of hydroxyapatite, 8 parts of nano-silver powder, 6 parts of nano-titanium dioxide, 12 parts of glycerin, 15 parts of polyethyl acetate, 26 parts of citronella extract Parts, 6 parts of nano-silica, 15 parts of epoxy resin

[0022] The preparation method of the above-mentioned nano antibacterial bone filling material comprises the following steps:

[0023] Step 1, mix hydroxyapatite, nano-silver powder, nano-titanium dioxide, nano-silica and epoxy resin, grind to 800 mesh, put it into the reaction kettle, raise the temperature to 2200°C at a constant speed, keep it warm for 8 minutes, and continue to heat up to 2800°C °C to obtain the first mixed solution, wherein the rate of constant temperature rise is 8 °C / min, and the heating time is 0.8 hours;

[0024] Step 2, when the first mixed liquid is cooled to 45°C, add glycerin and citronella extract, and stir at...

Embodiment 3

[0026] A nano antibacterial bone filling material, comprising the following raw materials in parts by weight: 38 parts of hydroxyapatite, 10 parts of nano-silver powder, 8 parts of nano-titanium dioxide, 15 parts of glycerin, 18 parts of polyethyl acetate, 28 parts of citronella extract Parts, 8 parts of nano silicon dioxide, 18 parts of epoxy resin.

[0027] The preparation method of the above-mentioned nano antibacterial bone filling material comprises the following steps:

[0028] Step 1, mix hydroxyapatite, nano-silver powder, nano-titanium dioxide, nano-silica and epoxy resin, grind to 800 mesh, put it into the reaction kettle, raise the temperature to 2500°C at a constant speed, keep it warm for 10 minutes, and continue to heat up to 2800°C °C to obtain the first mixed solution, wherein the rate of constant temperature rise is 10 °C / min, and the heating time is 1 hour;

[0029] Step 2, when the first mixed liquid is cooled to 50°C, add glycerin and citronella extract, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com