Cyclone overflow pulp classification system and pulp classification process

A classification system and cyclone technology, which is applied in the cyclone overflow pulp classification system, cyclone overflow pulp classification process, and mineral processing systems, can solve the problems of high sorting cost, increased equipment load, and reduced target mineral recovery. The efficiency and other issues, to achieve simple and reliable process flow, improve economic efficiency, reduce the effect of equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

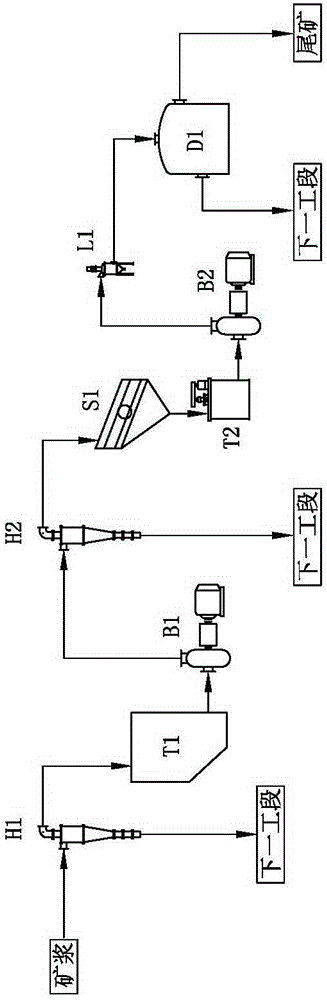

[0032] Such as figure 1As shown, the cyclone overflow slurry classification system of the present invention includes a primary cyclone H1, a buffer tank T1, a primary slurry pump B1, a secondary cyclone H2, a secondary slurry pump B2, and a slag separation screen S1, stirring tank T2, filter L1 and swash plate classifier D1, the overflow port of the primary cyclone H1 is connected to the inlet of the buffer tank T1, the outlet of the buffer tank T1 is connected to the inlet of the primary slurry pump B1, The outlet of the primary slurry pump B1 is connected to the inlet of the secondary cyclone H2, the overflow port of the secondary cyclone H2 is connected to the inlet of the slag separation screen S1, and the undersize outlet of the slag separation screen S1 is connected to the mixing tank The inlet of T2 is connected, the outlet of mixing tank T2 is connected with the inlet of secondary slurry pump B2, the outlet of secondary slurry pump B2 is connected with the inlet of fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com