Method for controlling temperature of copper brazing furnace

A temperature control method and temperature control technology, applied in the direction of manufacturing tools, welding equipment, welding/welding/cutting items, etc., can solve the problems of overshoot, PID parameters can not be obtained, etc., to achieve no cleaning, fast welding speed, welding good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

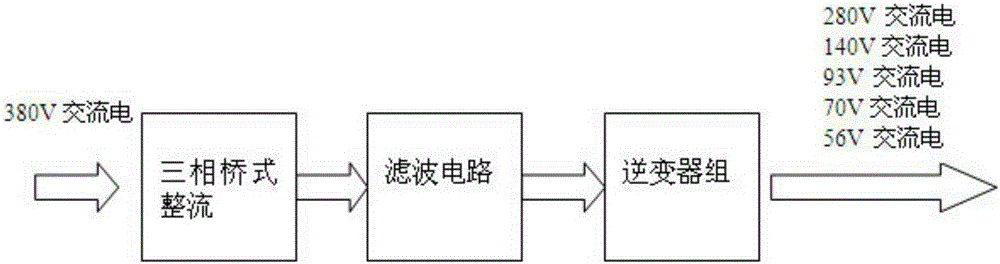

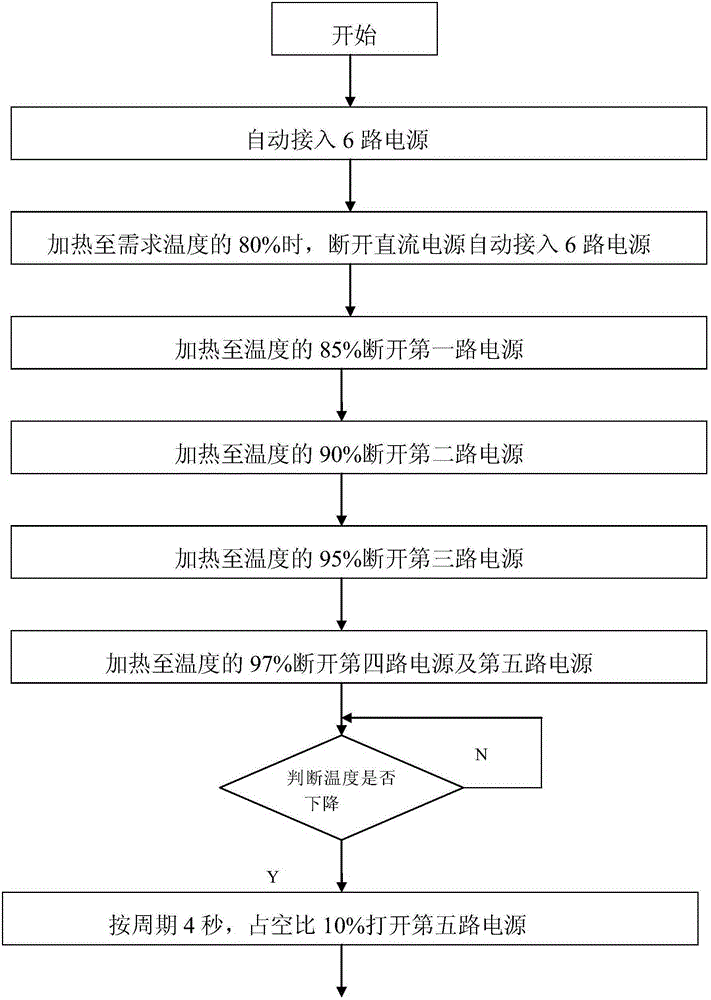

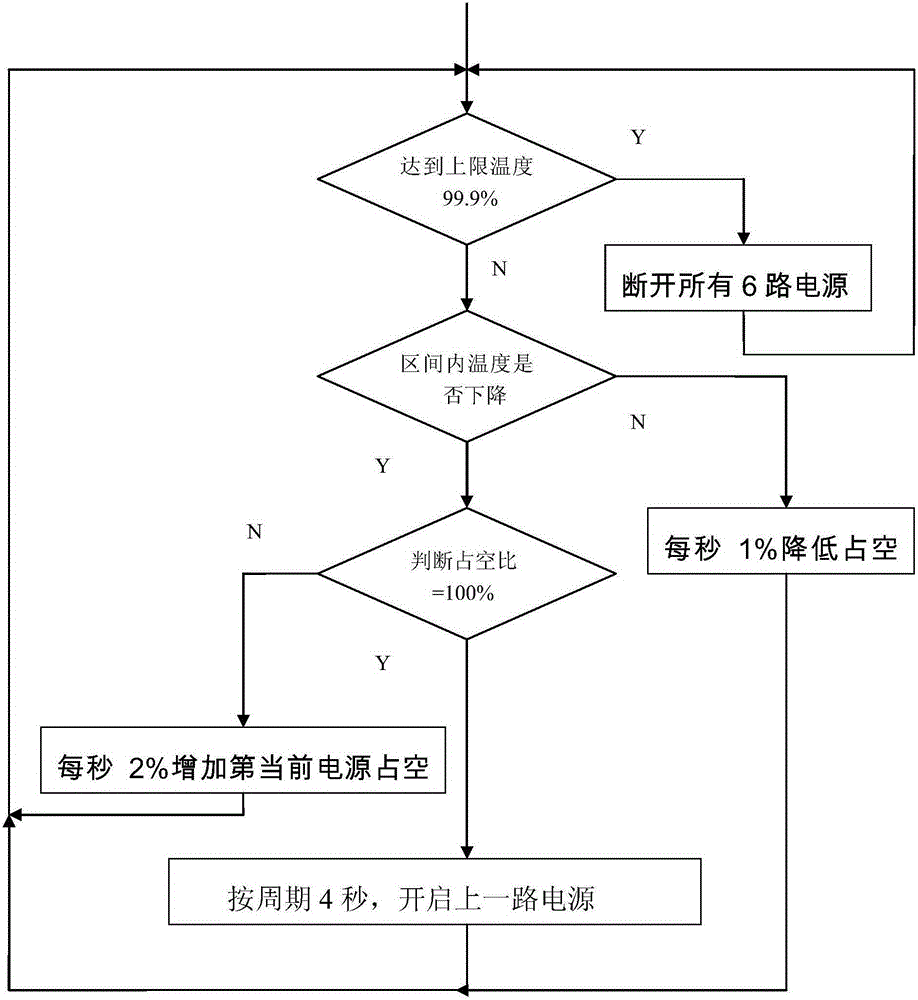

[0024] The temperature control method of copper brazing furnace is to convert 380V AC into DC through three-phase bridge rectification and filtering, and use the DC as the power supply for heating resistors, and then use the power inverter to convert the DC into AC with different amplitudes. The first power supply, the second power supply, the third power supply, the fourth power supply, the fifth power supply, and the above six power supplies are superimposed to form the total power supply of the heating resistor. The temperature in the copper brazing furnace is detected by PLC, and then Analysis and judgment control the number of heating resistor power supplies connected. The direct current is composed of 6 diodes to form a three-phase bridge rectifier circuit, and a ∏ filter circuit is formed through a capacitor and an inductance.

[0025] The amplitude of the first AC power supply is 280, and the frequency is 50Hz;

[0026] The amplitude of the second AC power supply is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com