Self-cleaning fluidized bed biofiltration device for aquaculture

A technology of biological filtration and mariculture, applied in seawater treatment, sustainable biological treatment, application, etc., can solve problems such as inability to attach biological communities, loss of filter material, difficulty in inoculation success, etc., to facilitate attachment and reproduction, and stable expansion height , the effect of promoting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

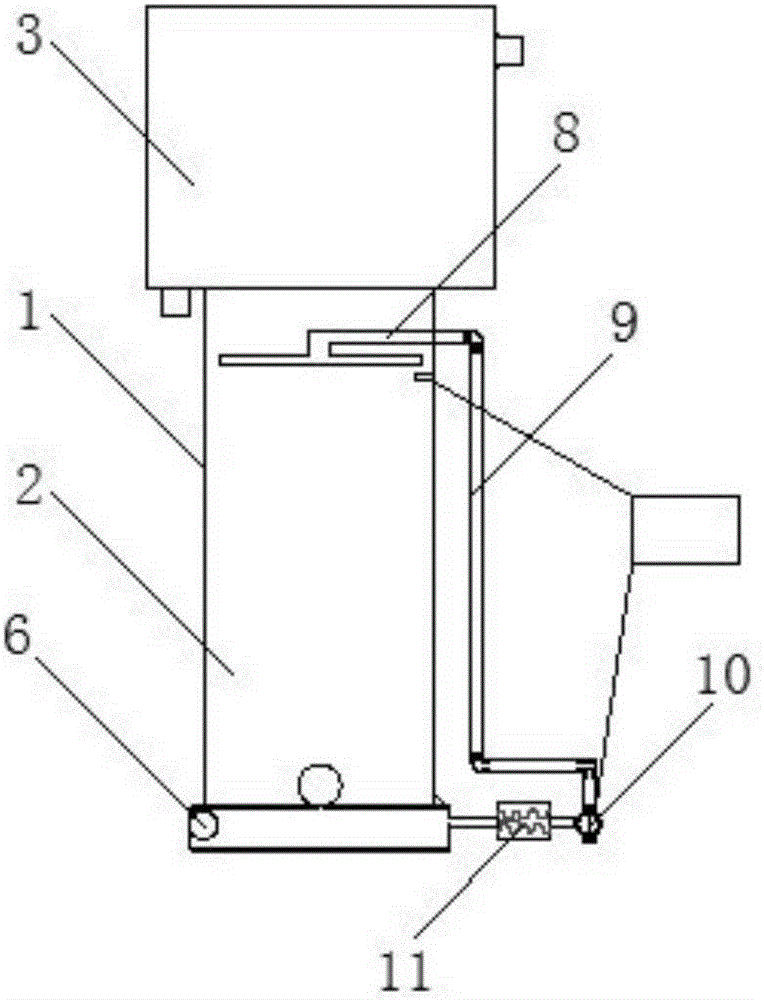

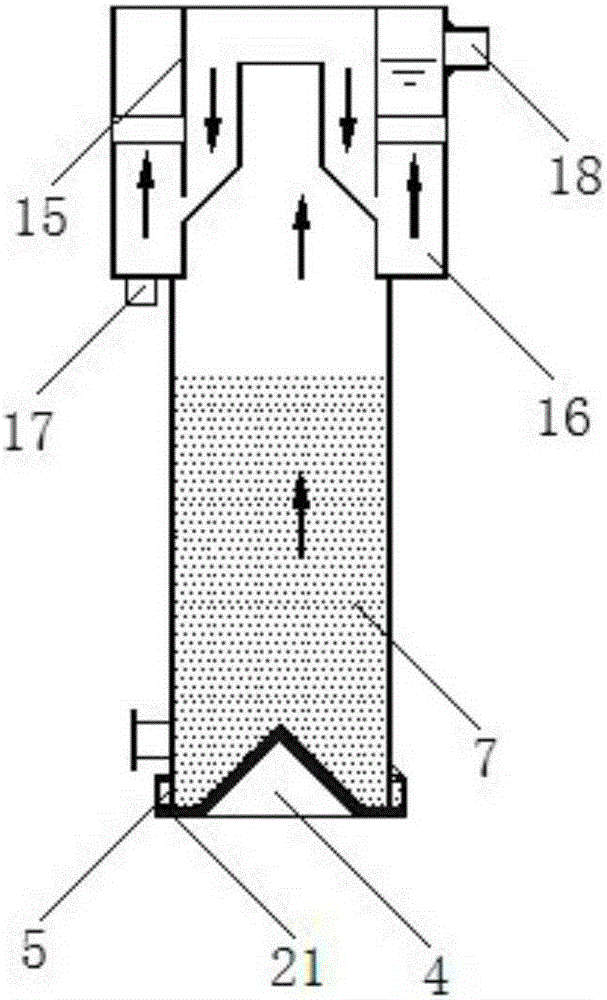

[0036] see figure 1 and figure 2 , a self-cleaning fluidized bed biological filter device for marine aquaculture, comprising a cylinder 1, a bed expansion zone 2 and a suspended matter sedimentation zone 3 are arranged inside the cylinder 1.

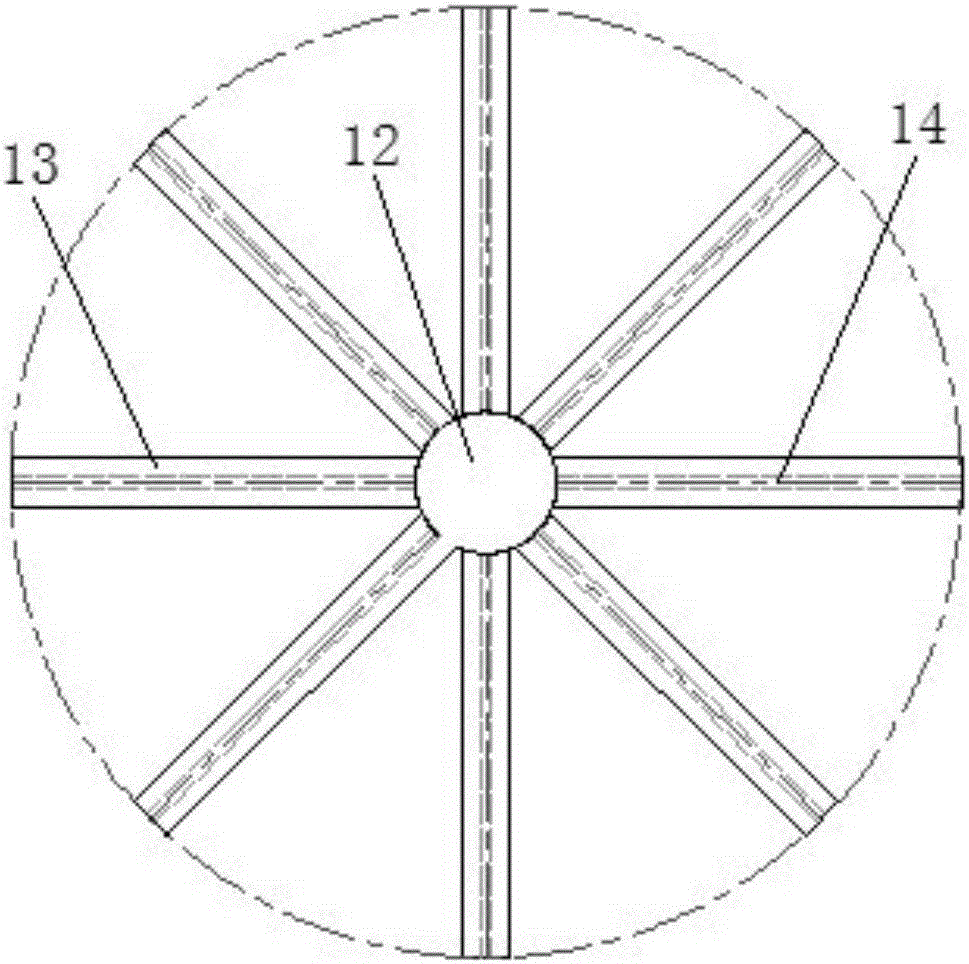

[0037] The bottom of the bed expansion zone 2 is provided with a conical water distribution plate 4 for water inlet, and the outer wall of the bottom of the bed expansion zone 2 is provided with an annular water distribution chamber 5, and the annular water distribution chamber 5 The bottom is connected to the bed expansion zone 2 through the annular water distribution gap 21 at the bottom, and the other end of the annular water distribution chamber 5 is set as a water inlet 6, and the water inlet directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com