Rear earth-doped luminescent glass for white light emitting diode and preparation method therefor

A technology of rare earth doping and glass, which is applied in lighting engineering technology and optoelectronics field, can solve the problems of insufficient green light emission and achieve high color rendering index, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

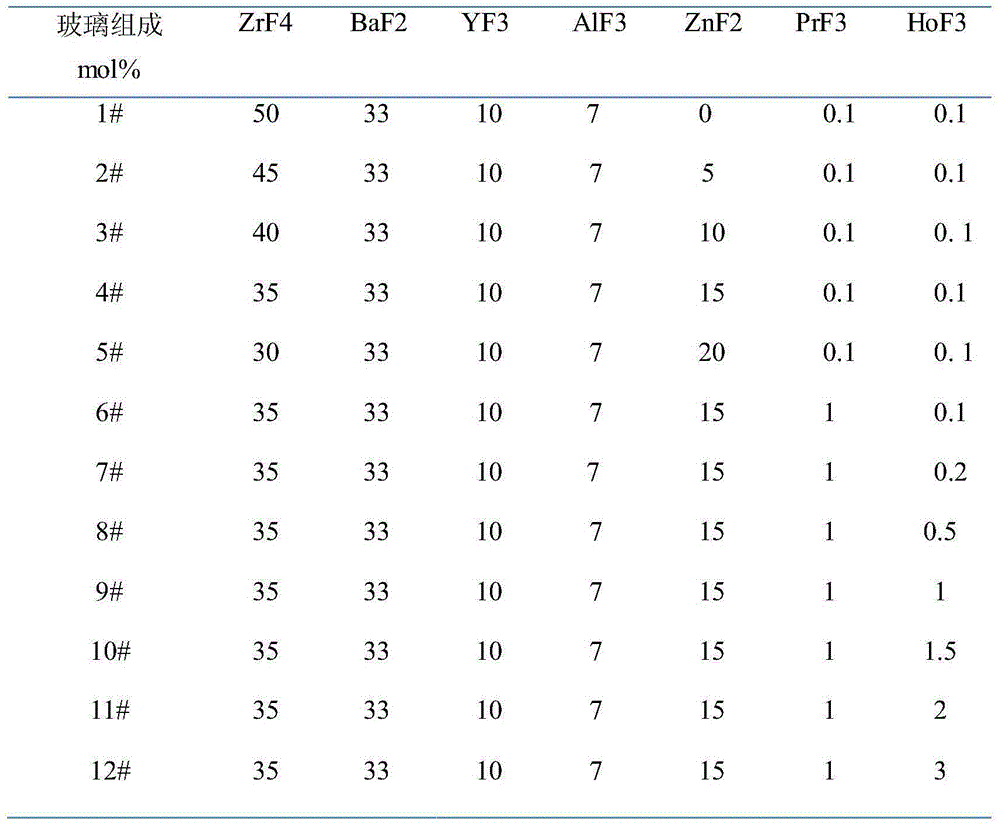

[0028] The raw material composition is as shown in Table 1#, and the specific preparation process is as follows:

[0029] According to the molar percentage of the 1# glass composition in the table, calculate the corresponding weight percentage of each composition, weigh each raw material and mix them evenly; put the mixed material into a platinum crucible and melt it in a silicon carbide rod electric furnace at 900 °C until it is completely melted After clarifying for 10 minutes, pour the molten glass on the preheated mold at 300°C; quickly move the glass into a muffle furnace that has been heated to 330°C for annealing, keep it warm for 4 hours, and then lower it to room temperature at a rate of 10°C / hour , and the glass sample was taken out after complete cooling to obtain a rare earth doped fluoride glass.

Embodiment 2

[0031] The raw material composition is as shown in Table 2#, and the specific preparation process is as follows:

[0032] According to the molar percentage of the 2# glass composition in the table, calculate the corresponding weight percentage of each composition, weigh each raw material and mix them evenly; put the mixed material into a platinum crucible and melt it in a silicon carbide rod electric furnace at 910°C until completely melted After clarifying for 15 minutes, pour the molten glass on the mold preheated at 300°C; quickly move the glass into a muffle furnace that has been heated to 340°C for annealing, keep it warm for 6 hours, and then lower it to room temperature at a rate of 10°C / hour , and the glass sample was taken out after complete cooling to obtain a rare earth doped fluoride glass.

Embodiment 3

[0034] The raw material composition is as shown in Table 3#, and the specific preparation process is as follows:

[0035] According to the molar percentage of the 3# glass composition in the table, calculate the corresponding weight percentage of each composition, weigh each raw material and mix them evenly; put the mixed material into a platinum crucible and melt it in a silicon carbide rod electric furnace at 920°C until completely melted After clarifying for 15 minutes, pour the molten glass on the mold preheated at 320°C; quickly move the glass into a muffle furnace that has been heated to 340°C for annealing, keep it warm for 6 hours, and then lower it to room temperature at a rate of 15°C / hour , and the glass sample was taken out after complete cooling to obtain a rare earth doped fluoride glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com