Granular bio-organic fertilizer and preparation method thereof

A bio-organic fertilizer and granule technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of high manufacturing cost, many raw materials, unfavorable promotion, etc., and achieve the effects of reducing production costs, easy absorption, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

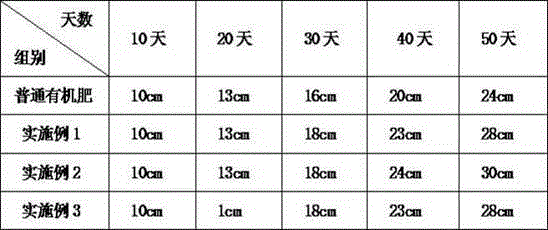

Examples

Embodiment 1

[0026] A preparation method of granular bio-organic fertilizer, comprising the following steps:

[0027] 1) Put 12 parts of lignite, 8 parts of urea, 6 parts of silkworm excrement, 10 parts of vermicompost, 15 parts of edible fungus residue, and 15 parts of straw into the mixer for 10-12 minutes, then discharge into the pulverizer crushed, filtered through a filter to obtain particles with a diameter of less than 20 mesh, and set aside;

[0028] 2) Put the granules obtained in step 1) into the heating barrel, add water to submerge the raw materials for 5-8cm, boil on high heat for 30-50 minutes, turn off the fire, wait until the temperature drops to room temperature, and set aside;

[0029] 3) Mix 1 part of yeast, 1 part of Lactobacillus plantarum, 2 parts of Enterococcus faecalis, 5 parts of protease, 7 parts of corn gluten powder, 6 parts of whey powder, and 3 parts of lactose, add the same quality of water, and put it in the basin , covered with a wet towel, stored in an e...

Embodiment 2

[0035] A preparation method of granular bio-organic fertilizer, comprising the following steps:

[0036] 1) Put 13 parts of lignite, 9 parts of urea, 8 parts of silkworm excrement, 11 parts of vermicompost, 17.5 parts of edible fungus residue, and 20 parts of straw into the mixer for 10-12 minutes, then discharge into the pulverizer crushed, filtered through a filter to obtain particles with a diameter of less than 20 mesh, and set aside;

[0037] 2) Put the granules obtained in step 1) into the heating barrel, add water to submerge the raw materials for 5-8cm, boil on high heat for 30-50 minutes, turn off the fire, wait until the temperature drops to room temperature, and set aside;

[0038] 3) Mix 2 parts of yeast, 2 parts of Lactobacillus plantarum, 3 parts of Enterococcus faecalis, 5.5 parts of protease, 8 parts of corn gluten powder, 8 parts of whey powder, and 4 parts of lactose, add the same quality of water, and put it in the pot , covered with a wet towel, stored in ...

Embodiment 3

[0044] A preparation method of granular bio-organic fertilizer, comprising the following steps:

[0045] 1) Put 14 parts of lignite, 10 parts of urea, 10 parts of silkworm excrement, 12 parts of vermicompost, 20 parts of edible fungus residue, and 25 parts of straw into the mixer and stir for 10-12 minutes, then discharge into the pulverizer crushed, filtered through a filter to obtain particles with a diameter of less than 20 mesh, and set aside;

[0046] 2) Put the granules obtained in step 1) into the heating barrel, add water to submerge the raw materials for 5-8cm, boil on high heat for 30-50 minutes, turn off the fire, wait until the temperature drops to room temperature, and set aside;

[0047] 3) Mix 3 parts of yeast, 3 parts of Lactobacillus plantarum, 4 parts of Enterococcus faecalis, 6 parts of protease, 9 parts of corn gluten powder, 10 parts of whey powder, and 5 parts of lactose, add the same quality of water, and put it in the basin , covered with a wet towel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com