Method for preparing hydroxyapatite and chitosan with shrimp and crab shells as raw materials

A technology of hydroxyapatite and shrimp and crab shells, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as the inability to utilize shrimp and crab shells, achieve simplified pretreatment processes, reduce production costs, and improve utilization rates high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Shrimp shell pretreatment: directly dry the shrimp shell and pulverize it into powder for later use.

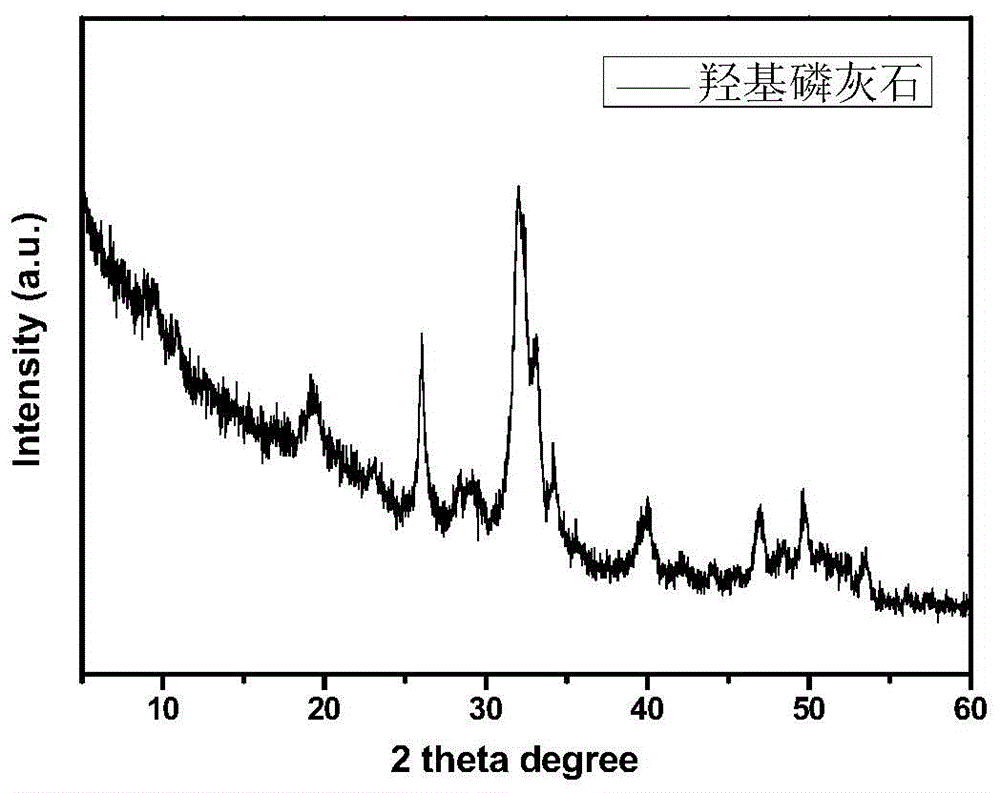

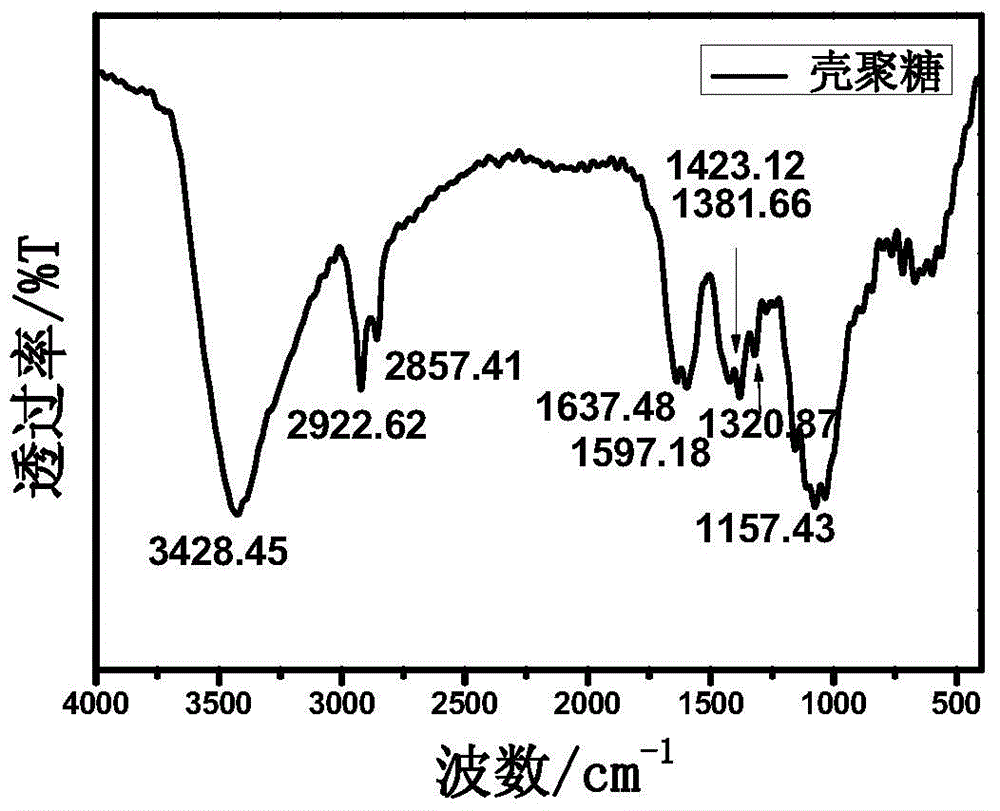

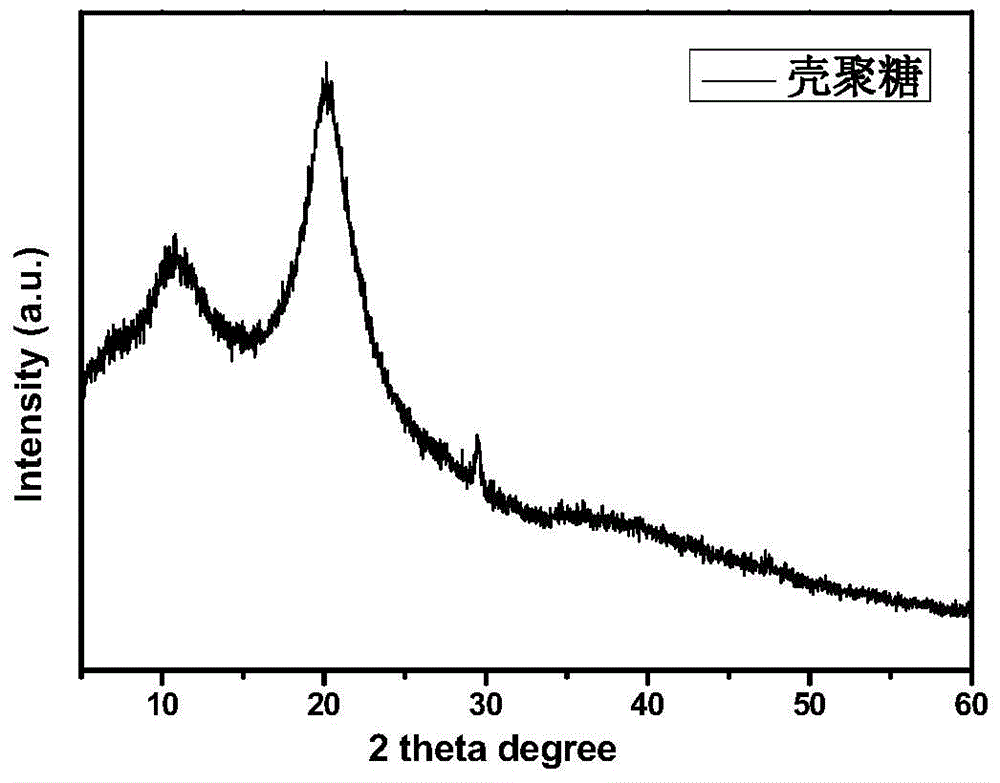

[0029] (2) Microwave reaction: Weigh 40g shrimp shell raw material powder and put it into a microwave reactor, add 4.67g diammonium hydrogen phosphate and 4.07g ammonium dihydrogen phosphate and 2.5L deionized water, stir well, and oxidize with 10wt% hydroxide Adjust the pH value of the sodium solution at 10.0, control the reaction temperature at 90°C by adjusting the microwave reaction power of 400w, and the reaction time is 4h. The product after the microwave reaction is washed with deionized water and dried to obtain nano-hydroxyapatite-chitosan powder Body 16.8520g.

[0030] (3) product separation: the 16.8520g nano-hydroxyapatite-chitosan powder body that step (2) obtains is added deionized water, slowly adds the dilute hydrochloric acid of 10wt% while stirring at room temperature and adjusts the pH value to 4.0, in After stirring for 2 hours at room temperat...

Embodiment 2

[0034] (1) Shrimp shell pretreatment: directly dry the shrimp shell and pulverize it into powder for later use.

[0035] (2) Microwave reaction: Weigh 40g shrimp shell raw material powder and put it into a microwave reactor, add 4.67g diammonium hydrogen phosphate and 4.07g ammonium dihydrogen phosphate and 2.5L deionized water, stir well, and oxidize with 15wt% hydroxide The pH value of the sodium solution is adjusted to 12.0, the reaction temperature is controlled at 100°C by adjusting the microwave reaction power of 500w, and the reaction time is 2h. The product after the microwave reaction is washed with deionized water and dried to obtain nano-hydroxyapatite-chitosan Powder 15.9876g.

[0036] (3) product separation: the 15.9876g nano-hydroxyapatite-chitosan powder body that step (2) obtains is added deionized water, slowly adds the dilute hydrochloric acid of 15wt% while stirring at room temperature and adjusts the pH value to be 6.5, in After stirring at room temperatur...

Embodiment 3

[0039] (1) Crab shell pretreatment: directly dry the crab shell and pulverize it into powder for later use.

[0040] (2) Microwave reaction: Weigh 40g crab shell raw material powder and put it into a microwave reactor, add 6.34g diammonium hydrogen phosphate and 5.52g ammonium dihydrogen phosphate and 2.5L deionized water, stir well, and oxidize with 5wt% hydroxide The pH value of the sodium solution is adjusted to 8.0, the reaction temperature is controlled at 90°C by adjusting the microwave reaction power of 400w, and the reaction time is 8h. The product after the microwave reaction is washed with deionized water and dried to obtain nano-hydroxyapatite-chitosan Powder 18.9652g.

[0041] (3) product separation: the 18.9652g nano-hydroxyapatite-chitosan powder body that step (2) obtains is added deionized water, slowly adds the dilute hydrochloric acid of 5wt% while stirring at room temperature and adjusts the pH value to 4.0, in After stirring at room temperature for 6 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com