Rhenium extracting method

A reaction zone and roasting technology, which is applied in the field of extracting rhenium, extracting rhenium from rhenium-containing ore to obtain rhenium-containing extract solution, can solve the problems of large loss of rhenium, low volatilization rate of rhenium, low efficiency of rhenium oxidation and roasting, etc., and achieve improvement Production efficiency, increase rhenium volatilization rate, and improve the effect of oxidation roasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

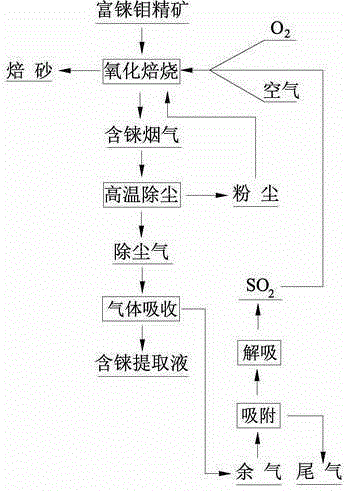

[0049] The method for extracting rhenium of the present invention, technological process such as figure 1 As shown, including the following process steps:

[0050] (1) Oxidation roasting of rhenium-containing ore

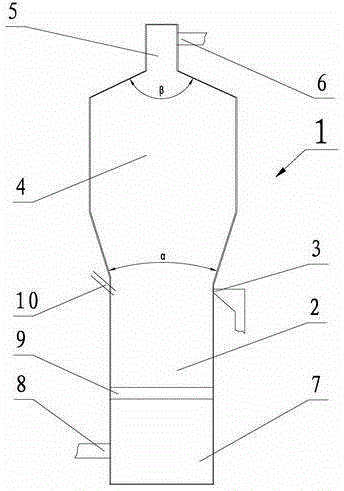

[0051] Send the rhenium-containing ore into the fluidized fluidized furnace, and contact with oxygen-containing air for roasting; the specific structure of the fluidized fluidized furnace is as follows: image 3 As shown, the lower part of the fluidized fluidized furnace is provided with a perforated gas distribution partition 9, that is, the furnace bottom. Below the furnace bottom is an air chamber 7 provided with an air inlet pipe 8. The air inlet pipe 8 is connected to the air supply system, and the furnace body 1 is upwards 1.0 along the furnace bottom At a height of ~1.5m, there are respectively a feed inlet 10 and a discharge outlet 3. The feed inlet 10 is slightly higher than the discharge outlet 3. The fluidized furnace body 1 is provided with a mixed reac...

Embodiment 2

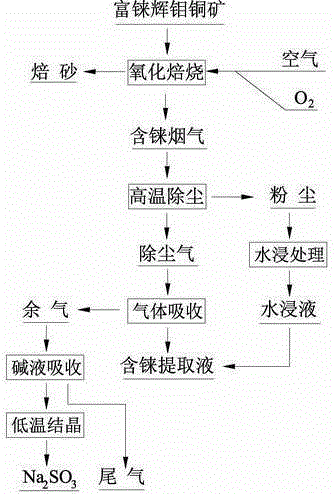

[0072] Using rhenium-rich molybdenite as raw material, the rhenium in the mineral is extracted by oxidizing and roasting. The rhenium content of the raw material is 530g / t. The process flow is as follows figure 2 As shown, including the following process steps:

[0073] (1) Oxidation roasting of rhenium-containing ore

[0074] Send the rhenium-containing ore raw materials into the fluidized fluidized furnace, and contact with oxygen-containing air for roasting; the specific structure of the fluidized fluidized furnace is as follows: image 3As shown, the fluidized furnace body 1 is provided with a mixed reaction zone 2 and a second reaction zone, the second reaction zone is higher than the discharge port 3 and is provided with an enlarged diameter section 4 and a reduced diameter section 5 along the furnace body 1 upwards. The diameter ratio between section 4 and mixing reaction zone 2 is 1.4:1. The junction of diameter expanding section 4 and mixing reaction zone 2 is in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com