Method for manufacturing rare earth enhanced type magnalium gadolinium tin alloy plate

A type of magnesium-aluminum-gadolinium-tin and magnesium-aluminum-gadolinium-tin technology is applied in the field of preparation of rare earth-enhanced magnesium-aluminum-gadolinium-tin alloy plates, which can solve problems such as poor corrosion resistance, poor hardness, and poor high-temperature resistance, and achieve advanced technology, Improved corrosion resistance, accurate and detailed technical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with accompanying drawing:

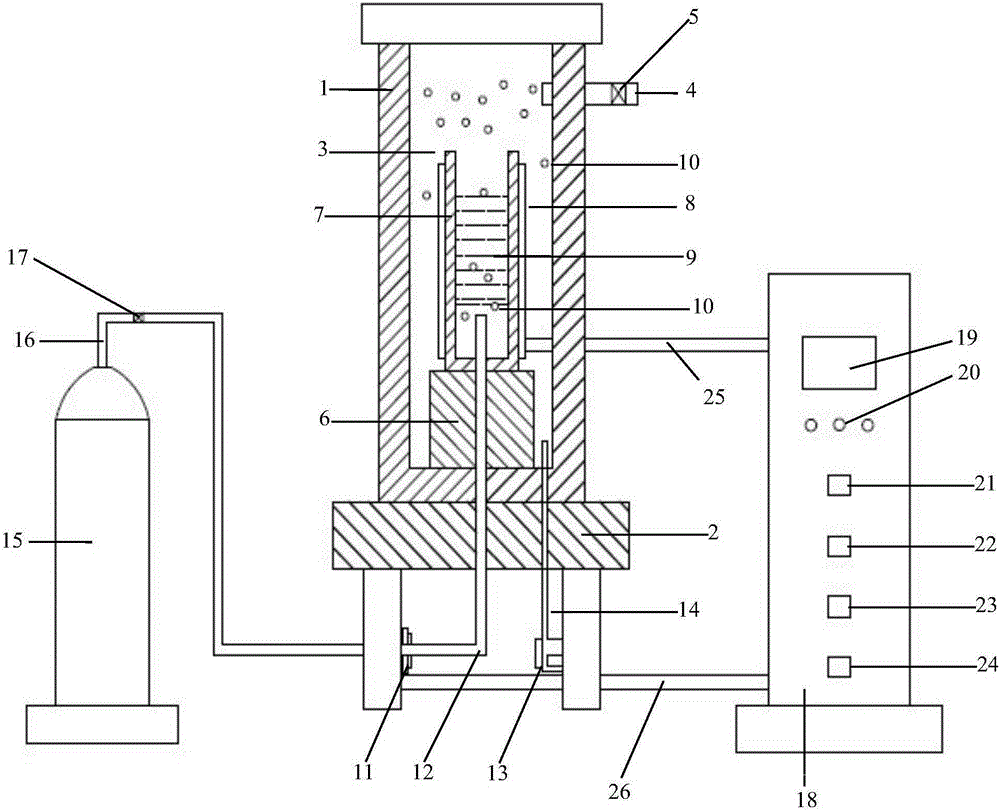

[0082] figure 1 As shown, it is the smelting state diagram of the magnesium-aluminum-gadolinium-tin alloy liquid. The position and connection relationship of each part must be correct, and the proportion should be adjusted according to the quantity, and the operation should be carried out in sequence.

[0083] Quantities of chemicals used in preparation are determined in pre-set ranges in grams, milliliters, centimeters 3 is the unit of measurement.

[0084] The smelting of magnesium-aluminum-gadolinium-tin alloy liquid is carried out in a vacuum smelting furnace, which is completed in the process of heating smelting, vacuuming, and argon bottom blowing;

[0085] The vacuum melting furnace is vertical, the lower part of the vacuum melting furnace 1 is the furnace seat 2, and the inside is the furnace chamber 3; the inner bottom of the furnace chamber 3 is a workbench 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com