Samarium-tin-copper alloy electroplating solution and electroplating method thereof

A copper alloy and electroplating solution technology, applied in the field of electroplating solution, can solve the problems of poor wear resistance and corrosion resistance of the coating, difficulty in obtaining a stable coating, poor stability, etc., and achieve strong corrosion resistance, good stability and Dispersion ability, combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

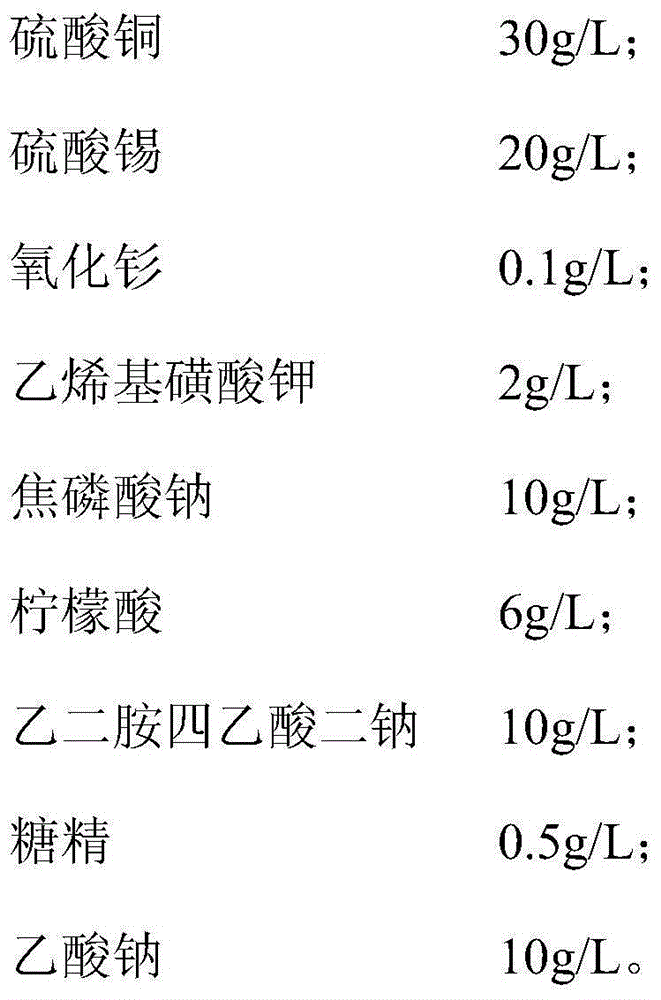

[0021] Embodiment 1: the samarium-tin-copper alloy electroplating solution of the present embodiment comprises following components:

[0022]

[0023] Use above-mentioned samarium-tin-copper alloy electroplating solution electroplating method as follows:

[0024] Configure samarium-tin-copper alloy electroplating solution: dissolve citric acid, potassium vinylsulfonate and sodium pyrophosphate in deionized water to form a solution, add copper sulfate, tin sulfate and samarium oxide to the solution, stir and dissolve to prepare into a mixed solution, adding saccharin, sodium acetate and disodium edetate to the mixed solution to dissolve to obtain a samarium-tin-copper alloy electroplating solution; wherein, in the samarium-tin-copper alloy electroplating solution Copper sulfate 30g / L, tin sulfate 20g / L, samarium oxide 0.1g / L, potassium vinylsulfonate 2g / L, sodium pyrophosphate 10g / L, citric acid 6g / L, disodium edetate 10g / L L, saccharin 0.5g / L and sodium acetate 10g / L, pH i...

Embodiment 2

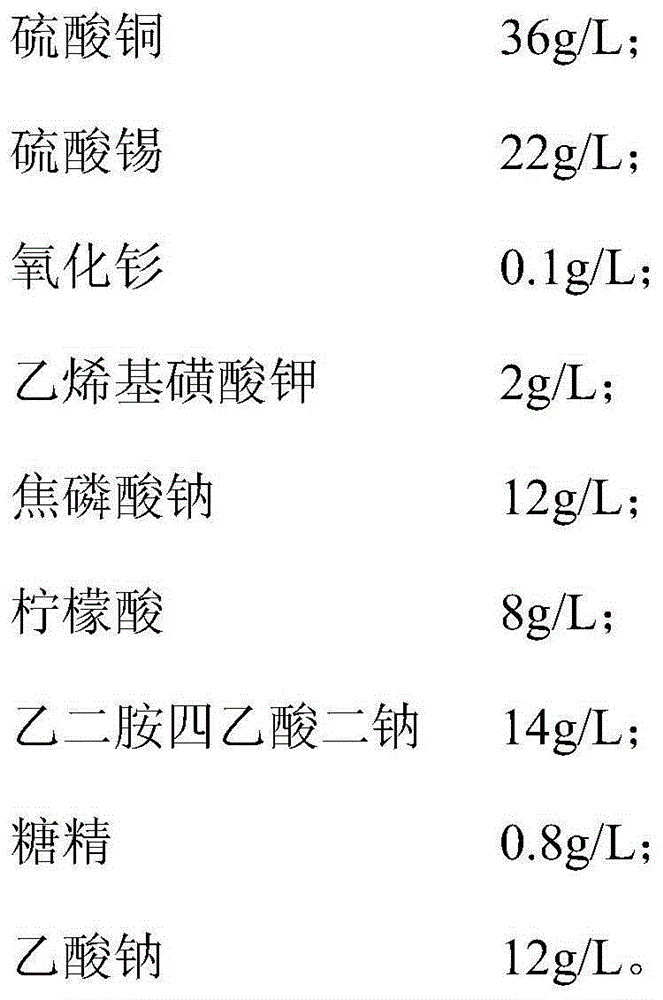

[0026] Embodiment 2: the samarium-tin-copper alloy electroplating solution of the present embodiment comprises following components:

[0027]

[0028] Use above-mentioned samarium-tin-copper alloy electroplating solution electroplating method as follows:

[0029] Configure samarium-tin-copper alloy electroplating solution: dissolve citric acid, potassium vinylsulfonate and sodium pyrophosphate in deionized water to form a solution, add copper sulfate, tin sulfate and samarium oxide to the solution, stir and dissolve to prepare into a mixed solution, adding saccharin, sodium acetate and disodium edetate to the mixed solution to dissolve to obtain a samarium-tin-copper alloy electroplating solution; wherein, in the samarium-tin-copper alloy electroplating solution Copper sulfate 36g / L, tin sulfate 22g / L, samarium oxide 0.1g / L, potassium vinylsulfonate 2g / L, sodium pyrophosphate 12g / L, citric acid 8g / L, disodium edetate 14g / L L, saccharin 0.8g / L and sodium acetate 12g / L, pH i...

Embodiment 3

[0031] Embodiment 3: the samarium-tin-copper alloy electroplating solution of the present embodiment comprises following components:

[0032]

[0033]

[0034] Use above-mentioned samarium-tin-copper alloy electroplating solution electroplating method as follows:

[0035] Configure samarium-tin-copper alloy electroplating solution: dissolve citric acid, potassium vinylsulfonate and sodium pyrophosphate in deionized water to form a solution, add copper sulfate, tin sulfate and samarium oxide to the solution, stir and dissolve to prepare into a mixed solution, adding saccharin, sodium acetate and disodium edetate to the mixed solution to dissolve to obtain a samarium-tin-copper alloy electroplating solution; wherein, in the samarium-tin-copper alloy electroplating solution Copper sulfate 38g / L, tin sulfate 25g / L, samarium oxide 0.2g / L, potassium vinylsulfonate 3g / L, sodium pyrophosphate 14g / L, citric acid 10g / L, edetate disodium 14g / L L, saccharin 1.2g / L and sodium acetat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com