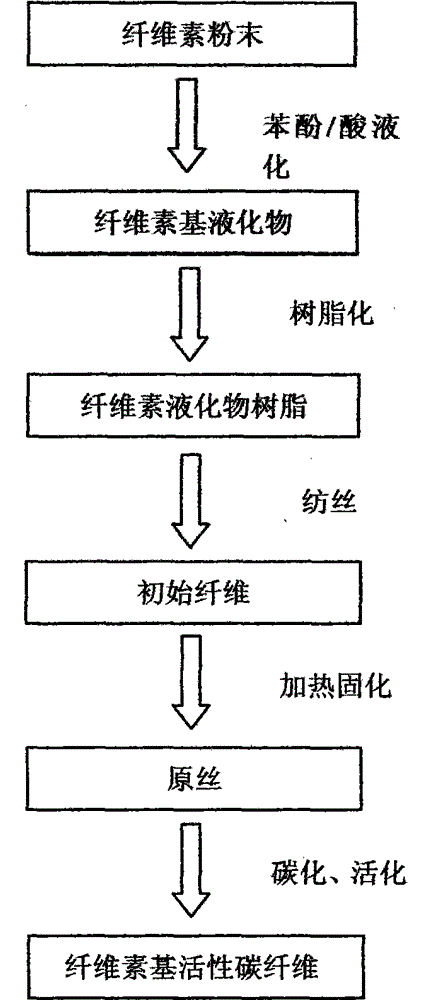

Method for preparing active carbon fibers from cellulose

A technology of activated carbon fiber and cellulose, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of single utilization route and low added value, and achieve the effects of diverse acquisition routes, improved comprehensive utilization rate, and wide range of material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation of embodiment 1 cellulose-based activated carbon fibers

[0034] Get a certain amount of cellulose powder (particle size: 120 mesh) and put it into the liquefaction device. Add phenol 4 times the weight of cellulose powder and sulfuric acid 0.1 times the weight of cellulose powder, mix and heat to 140°C, and keep it warm for 90 minutes to prepare cellulose liquefied resin; while heating, stir appropriately. After the liquefied product is cooled to room temperature, it is put into a spinning machine. When heated to 120°C, melt-spinning (spinning) is carried out at a speed of 100 rpm of the take-up roll to obtain initial fibers. Place the initial fiber in a blast drying oven, heat it to 120°C at a rate of 5°C / min, keep it warm for 2 hours, and take it out after cooling down to room temperature to obtain a carbon fiber precursor; weigh 15.30g of the precursor and place it in an activation device. Under the protection of nitrogen, heat up to 600°C at a rat...

Embodiment 2

[0036] The preparation of embodiment 2 cellulose-based activated carbon fibers

[0037] Get a certain amount of cellulose powder (80 mesh particle size) and put it into the liquefaction device. Add phenol 3 times the weight of cellulose powder and sulfuric acid 0.1 times the weight of cellulose powder, mix and heat to 120°C, and keep it warm for 90 minutes to prepare cellulose liquefied resin; while heating, stir appropriately. After the liquefied product is cooled to room temperature, it is put into a spinning machine. When heated to 120°C, melt spinning (spinning) is carried out at a speed of 80 r / min of the take-up roll to obtain initial fibers. Place the initial fiber in a blast drying oven, heat it to 140°C at a rate of 5°C / min, keep it warm for 2 hours, and take it out after cooling down to room temperature to obtain a carbon fiber precursor; weigh 10.20g of the precursor and place it in an activation device. Under the protection of nitrogen, heat up to 600°C at a rate...

Embodiment 3

[0039] The preparation of embodiment 3 cellulose-based activated carbon fibers

[0040]Get a certain amount of cellulose powder (60 mesh particle size) and put it into the liquefaction device. Add phenol 6 times the weight of cellulose powder and sulfuric acid 0.1 times the weight of cellulose powder, mix and heat to 120°C, and keep it warm for 90 minutes to prepare cellulose liquefied resin; while heating, stir appropriately. After the liquefied product is cooled to room temperature, it is put into a spinning machine. When heated to 120°C, melt-spinning (spinning) is carried out at a speed of 100 rpm of the take-up roll to obtain initial fibers. Place the initial fiber in a blast drying oven, heat it to 140°C at a rate of 5°C / min, keep it warm for 2 hours, and take it out after cooling down to room temperature to obtain a carbon fiber precursor; weigh 10.20g of the precursor and place it in an activation device. Under the protection of nitrogen, heat up to 600°C at a rate o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com