Halogen-free flame-retardant polyurethane resin slurry for leather and application thereof

A technology of polyurethane resin and wet-process polyurethane, which is applied in the field of polyurethane resin slurry for superfine fiber synthetic leather, can solve the problems of high price, high cost of flame retardancy, loss of practical application value, etc., and achieve the effect of little dyeing effect and soft hand feeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

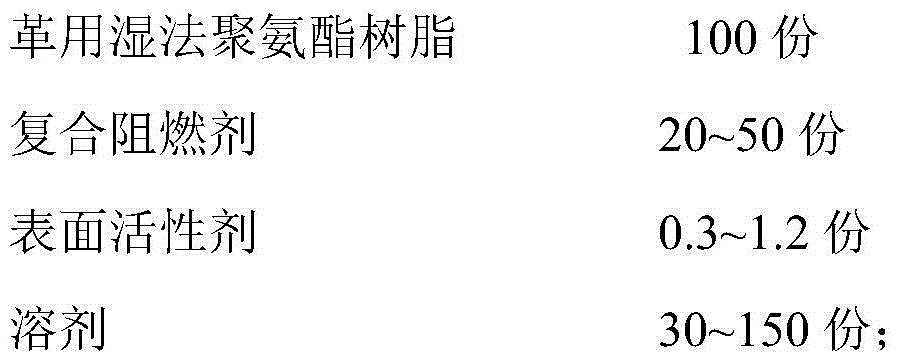

[0025] Mix leather with wet-process polyurethane resin, water-insoluble ammonium polyphosphate, aluminum dialkylphosphinate, surfactant, color paste, coupling agent and solvent to form a wet-process impregnation slurry. The components of the slurry are :

[0026] Polyester polyether copolymerized polyurethane resin…………100 parts

[0027] Water-insoluble ammonium polyphosphate…………………10 parts

[0028] Aluminum diethylphosphinate……………………10 parts

[0029] Surfactant JS-MS…………………… 0.3 parts

[0030] Solvent DMF………………………… 30 parts;

[0031] Among them: the water-insoluble ammonium polyphosphate is the APP-OM ammonium polyphosphate product of Zhenjiang Xingxing Flame Retardant Co., Ltd. with a degree of polymerization n=1500 and an average particle size of 6-7.5 μm;

[0032] The total solid weight portion of the flame-retardant polyurethane resin slurry for the leather of this component is 33.27%; With nylon 6 and polyethylene as raw material, the sea-island type short fiber is ir...

Embodiment 2

[0034] Mix leather with wet-process polyurethane resin, water-insoluble ammonium polyphosphate, aluminum dialkylphosphinate, surfactant, color paste, coupling agent and solvent to form a wet-process impregnation slurry. The components of the slurry are :

[0035] Polyether polyurethane resin……………………100 parts

[0036] Water-insoluble ammonium polyphosphate………………… 22 parts

[0037] Aluminum ethyl propyl phosphinate………………… 28 parts

[0038] Surfactant JS-MS…………………… 0.5 parts

[0039] Solvent DMF……………………… 150 parts

[0040] Silane coupling agent……………………… 0.7 parts

[0041] Polyethylene wax dispersant…………………… 0.7 parts;

[0042] Among them: the water-insoluble ammonium polyphosphate has a degree of polymerization n=2500 and an average particle size of 6-7.5 μm;

[0043] The total solid weight portion of the flame-retardant polyurethane resin slurry for the leather of this component is 26.50%; With nylon 6 and polyethylene as raw material, the sea-island type short fiber is iron...

Embodiment 3

[0045] Mix leather with wet-process polyurethane resin, water-insoluble ammonium polyphosphate, aluminum dialkylphosphinate, surfactant, color paste, coupling agent and solvent to form a wet-process impregnation slurry. The components of the slurry are :

[0046] Polyester-polycarbon-copolymerized polyurethane resin…………100 parts

[0047] Water-insoluble ammonium polyphosphate…………………15 parts

[0048] Aluminum dipropylphosphinate……………………30 parts

[0049] Surfactant JS-MS…………………… 0.9 parts

[0050] Surfactant JS-BT…………………… 0.3 parts

[0051] Solvent DMF………………………… 90 parts

[0052] Titanate coupling agent…………………… 1.5 parts

[0053] Black dye water……………………… 4 parts;

[0054] Among them: the water-insoluble ammonium polyphosphate is the APP-0S ammonium polyphosphate product of Zhenjiang Senhua Flame Retardant Engineering Technology Co., Ltd. with a degree of polymerization n≥1500 and an average particle size of 60-70 μm;

[0055] The total solid weight portion of the flame-re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com