Natural gas hydrate pipeline conveying and decomposing device

A technology of hydrate decomposition and pipeline transportation, applied in the direction of pipes, rigid pipes, pipe components, etc., can solve the problems of high equipment cost, poor economy, blocked pipes, etc., and achieve high spiral strength, no attenuation of spiral strength, and reduced resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with the accompanying drawings and specific embodiments, the content of the present invention is described in further detail:

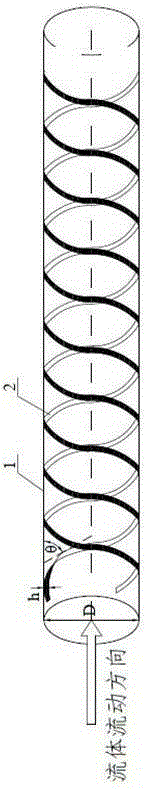

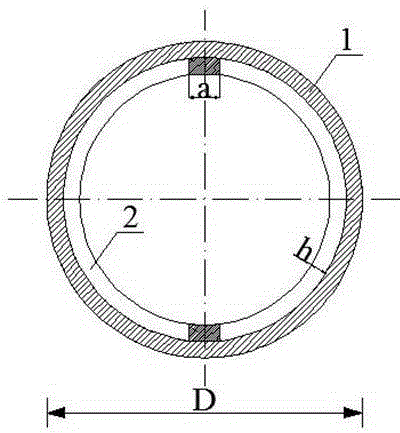

[0037] The helical flow generator in the present invention is as figure 1, consisting of a double-headed diversion strip, which is set along the inner wall of the pipeline; for the diversion strip, the width a is 0.01~0.1D, and the height h is 0.15~0.25D. Considering that the circumferential velocity of hydrate particles needs to be greater than the critical velocity, But it does not affect the axial flow, so the angle with the pipe wall is 15°~45°, the material is 16Mn, and the welding connection with the inner wall of the pipe is adopted. The schematic diagram of the installation section is as follows figure 2 shown.

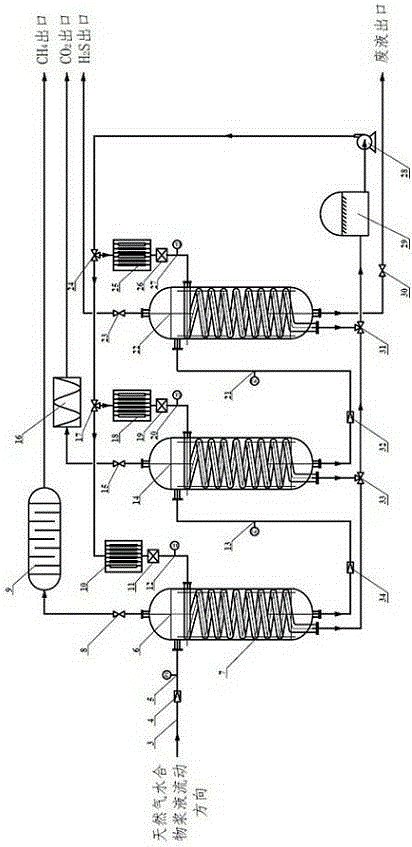

[0038] The hydrate decomposition process of the present invention is as follows image 3 As shown, the detailed scheme is as follows, the adopted device includes: the spiral pipeline 3 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com