Electromagnetic wave shielding sheet comprising carbon composite fiber manufactured by electrospinning and method for manufacturing same

一种制造方法、屏蔽板的技术,应用在静电纺丝、人造丝制造、磁场/电场屏蔽等方向,能够解决金属易发生氧化等问题,达到防止氧化、保证传导性、高电磁波屏蔽效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

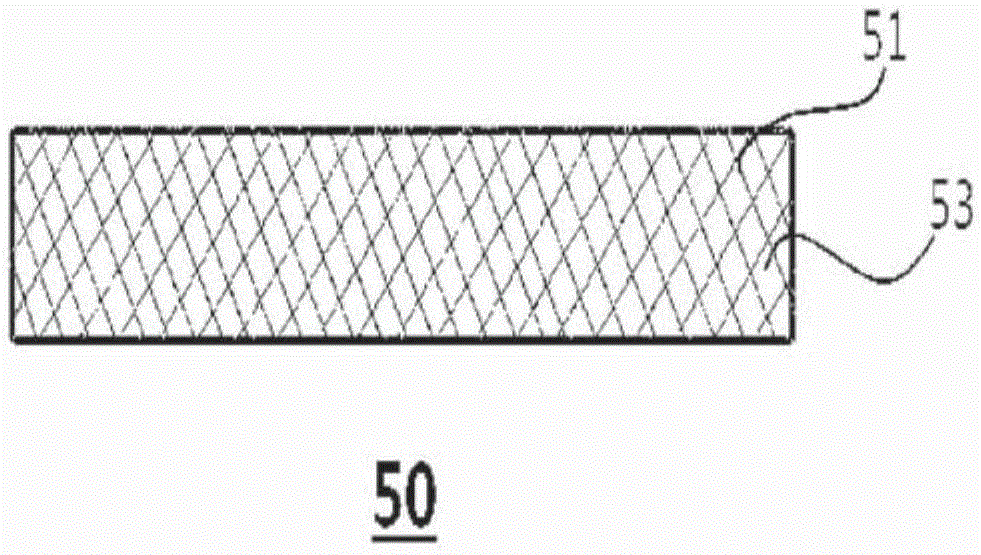

[0104] Example 1: Manufacturing of electromagnetic wave shielding board based on composite fiber mesh impregnation

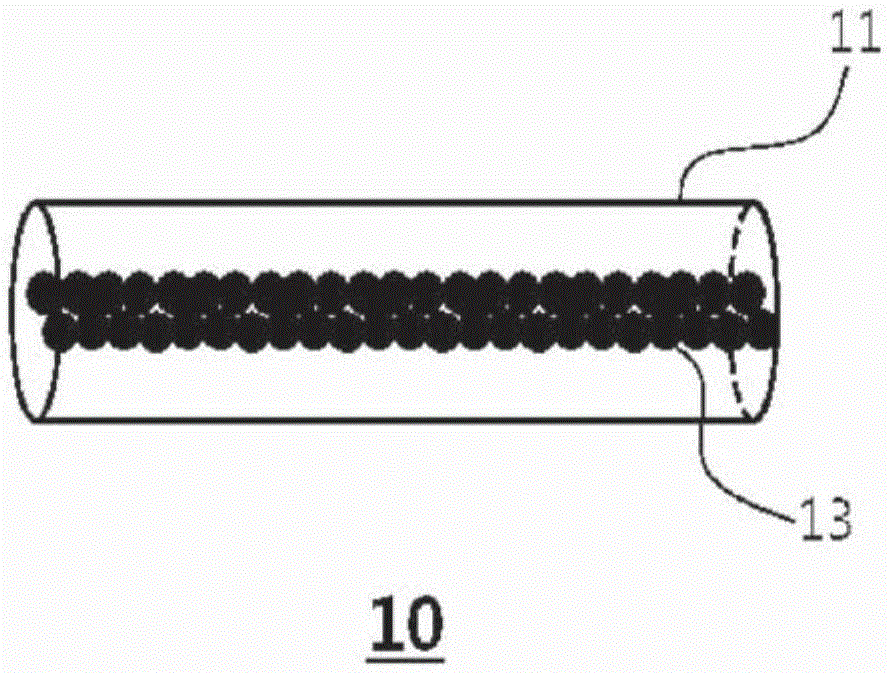

[0105] A solution (core) obtained by mixing 5 g of Cu with a particle size of 20-40 nm in ethanol was prepared as the first spinning solution, and a 12w% PAN solution (external) dissolved in DMF was prepared as the second spinning solution.

[0106] The first spinning solution and the second spinning solution are respectively connected to the inner and outer sides of the dual nozzles and set on a syringe pump, and then the flow rate is fixed at 0.005 ml / h. At this time, the collector and the spinneret are set vertically, and the collector is designed with conductive metal electrodes. The distance between the spinneret and the collector is fixed at 15 cm, and a voltage of 15 kV is applied to obtain a mesh-like composite fiber (100-500 nm in diameter).

[0107] The composite fiber was put into a heating furnace, and a carbonization process was performed at 1000° C. for ...

Embodiment 2

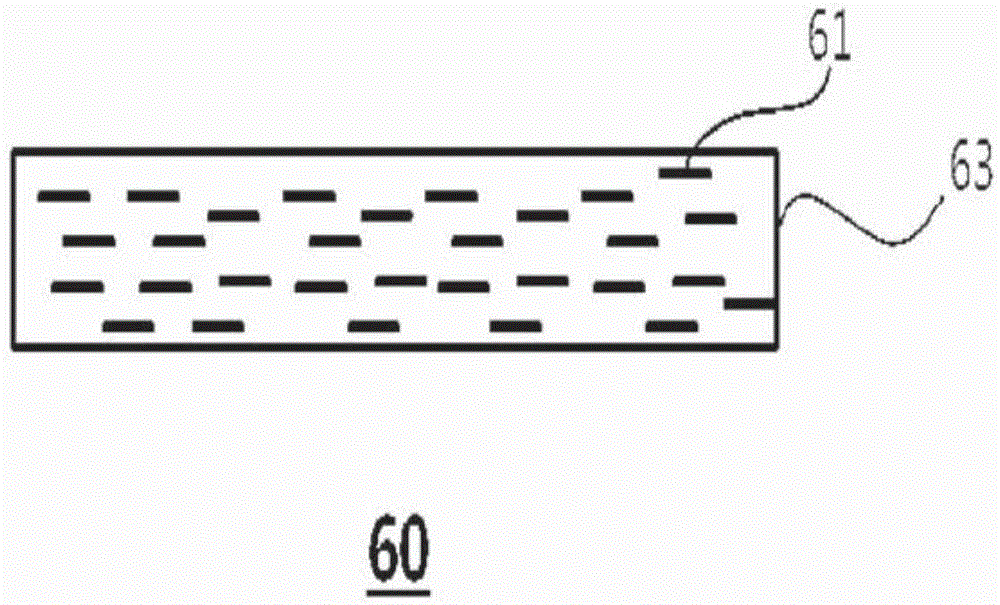

[0109] Example 2: Manufacturing based on short-cut composite fiberboard molding

[0110] The net-shaped core-shell carbon composite fiber manufactured in Example 1 was crushed with a length of 0.001 to 1 mm using a shredder. The obtained short-cut composite fiber is mixed with polymethyl methacrylate (PMMA) in a weight ratio of 1:3, and then pressure is applied, and an electromagnetic wave shielding plate is manufactured by plate molding.

Embodiment 3

[0111] Example 3: Manufacturing of electromagnetic wave shielding plate including Ag nanofibers in the core

[0112] It was carried out in the same manner as in Example 1, in which, as the first spinning solution, 3 g of AgNO was mixed with 3 A solution (core) obtained by mixing 5 grams of Cu with a particle size of 20-40 nm with 0.5 grams of PVP in 10 ml of ethanol solution (core). After manufacturing core-shell carbon composite fibers (Cu, Ag / CNF), perform the impregnation process To make an electromagnetic wave shielding board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com