Technology for extracting potato protein through hot flocculence method

A technology of potato protein and potato protein powder, which is applied in the direction of protein food components, protein components of waste, protein composition of microorganisms, etc., to achieve the effect of less investment, high purity and quality, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

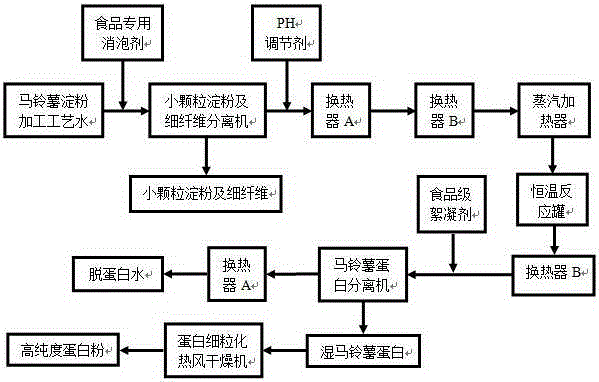

Image

Examples

Embodiment 1

[0030] (1) Separation of small granule starch and fine fiber: Use a built-in centripetal pump horizontal screw centrifuge to separate the mixture of small granule starch and fine fiber and potato protein juice in the potato processing starch process water. Potato processing starch process water intake is 30m 3 / h, extract the mixture of small granular starch and fine fiber at 6kg / m 3 ;The separated juice is used for protein separation;

[0031] (2) Separation of potato protein: add dilute sulfuric acid to the potato protein juice to adjust the pH value to 5.0, first use the spiral plate heat exchanger A and heat exchanger B to preheat, then use the direct steam heater to heat the temperature to 120 °C, and then pass Heat exchanger B recovers, preheats and cools down, and then separates through a horizontal screw centrifuge with a built-in centripetal pump, and the moisture content of the obtained wet potato protein is 80%; then continues to cool down to below 35°C through spi...

Embodiment 2

[0034] (1) Separation of small granule starch and fine fiber: add liquid defoamer (F-604) to the potato processing starch process water, the addition amount is 5mg / L, and use a built-in centripetal pump horizontal screw centrifuge to separate small granule starch and fine fiber Fine fiber mixture with potato protein juice. The water intake is 35m 3 / h, the amount of extracting small granular starch and fine fiber mixture is 6.2kg / m 3 ;The separated juice is used for protein separation;

[0035] (2) Separation of potato protein: add dilute hydrochloric acid to the potato protein juice to adjust the pH value to 4.8, first use the spiral plate heat exchanger A and heat exchanger B to preheat, and then use the direct steam heater to heat the temperature to 115 °C, and then Preheating and cooling through heat exchanger B, followed by separation through a horizontal screw centrifuge with a built-in centripetal pump, and the moisture content of the wet potato protein obtained is 81...

Embodiment 3

[0038] (1) Separation of small granule starch and fine fiber: add liquid defoamer (F-604) to the starch process water of potato processing, the addition amount is 8mg / L, and use a built-in centripetal pump horizontal screw centrifuge to separate small granule starch and fine fiber Fine fiber mixture with potato protein juice. The water intake is 40m 3 / h, the amount of extracting small granular starch and fine fiber mixture is 6.2kg / m 3 ;The separated juice is used for protein separation;

[0039] (2) Separation of potato protein: add acetic acid to the potato protein juice to adjust the pH value to 4.8, preheat with spiral plate heat exchanger A and heat exchanger B, and then use a direct steam heater to heat the temperature to 110°C, and then pass heat exchange Container B recovers, preheats and cools down, and then separates through a horizontal screw centrifuge with a built-in centripetal pump, and the moisture content of the obtained wet potato protein is 78%. Then con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com