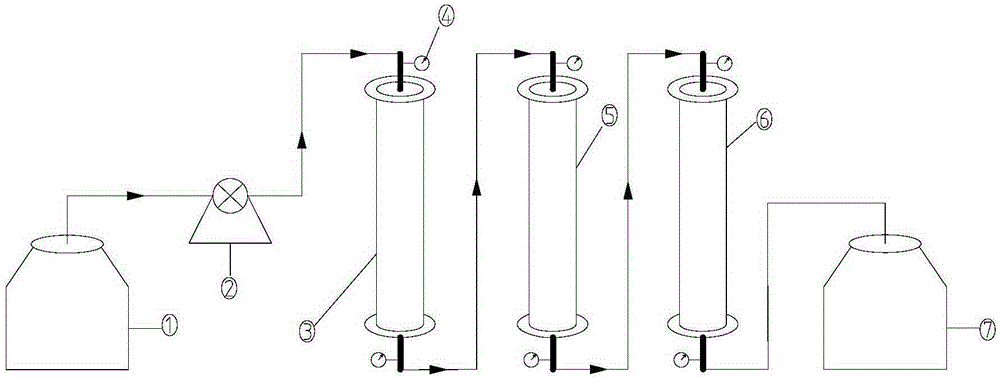

Method used for processing biogas slurry via boilogical filter combination filtering

A technology of biological filter material and biogas slurry, which is applied in the field of waste resource utilization, can solve the problems of single-stage filtration that cannot take into account the processing capacity, poor processing capacity buffering, clogged filter membrane, etc., and achieve good environmental benefits and economical efficiency. Benefits, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

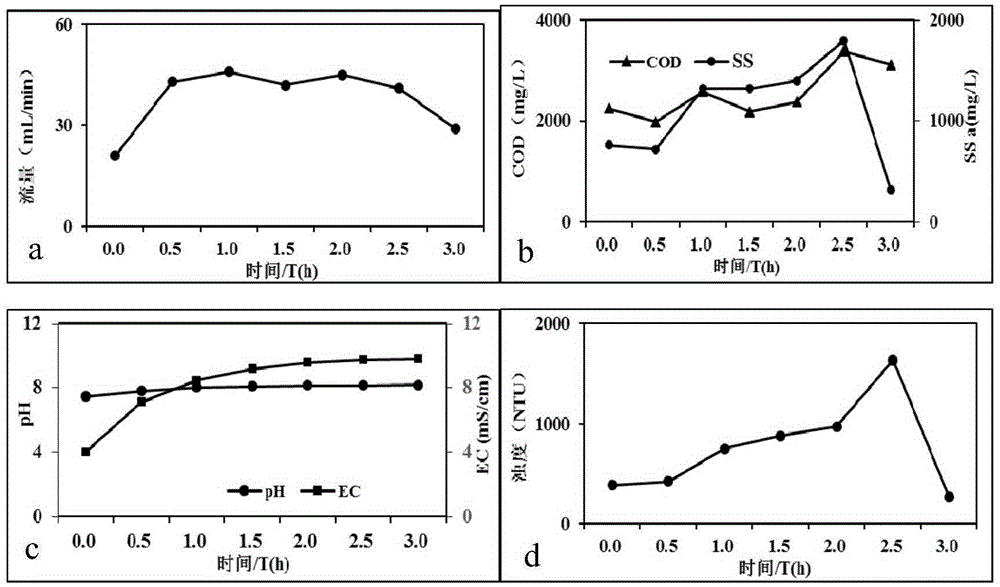

[0044] The influence of embodiment 1 different filter materials on filter effect under different conditions

[0045] Taking the type of filter material, the specification of the filter material, and the influent flow rate as three factors, each factor is set to three levels, and the single-stage filtration test is carried out according to the orthogonal design conditions shown in Table 5, and the pressure at the water inlet end is recorded during the filtration process. , water flow, water output, and regularly collect liquid samples to measure their pH, EC, COD, SS, and turbidity. Garden prunings and walnut sand materials are relatively hard and naturally piled up for filling, and their filling density and bulk density are the same, while corn straw is relatively fluffy, elastic and compressed, so it should be filled firmly, and the three specifications of thin, medium and thick straws should be packed firmly. The packing density is 0.09952, 0.1019, 0.09394g / cm3 .

[0046] T...

Embodiment 2

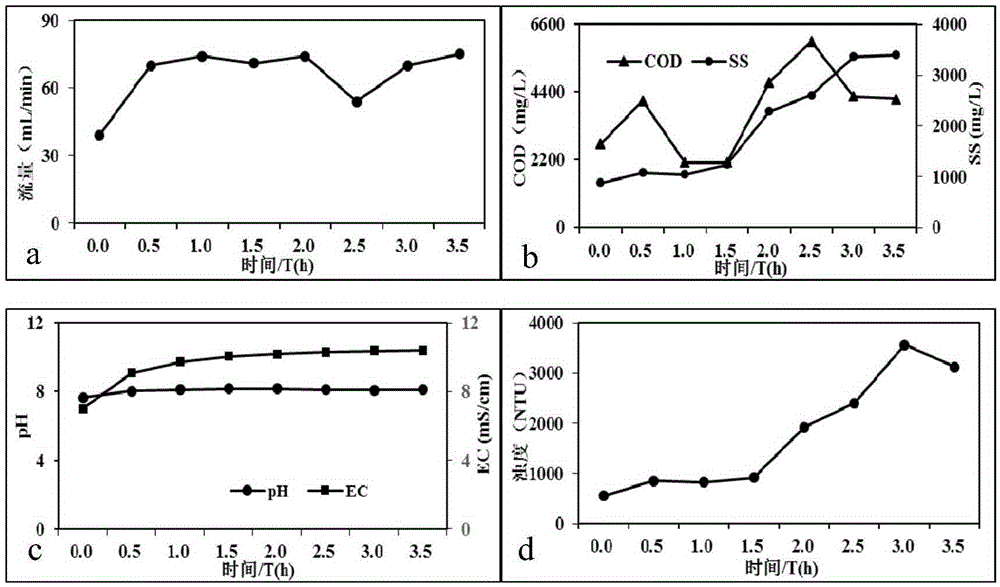

[0061] Example 2 Orthogonal test effect verification and three-stage series combination filter effect analysis

[0062] Coarse corn stalks were used as the primary filter, fine corn stalks were used as the secondary filter, and fine walnut sand was used as the tertiary filter. The influent water of the secondary filtration and the effluent water of the secondary filtration are used as the influent water of the tertiary filtration. The operation of each level of filtration is monitored, and the statistical analysis of the water volume and effluent indicators of each level of filtration, and the treatment volume and effluent status of each level of filtration As shown in Table 9. When the first stage of coarse corn stalks is filtered, a total of 24L of water is discharged from the beginning of water discharge to the clogging of the column, and the treated water volume per unit volume of the filter material reaches 3.82, which is 38% higher in processing capacity than the largest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com