A kind of ecological planting ceramsite and preparation method thereof

A technology of ecological planting and ceramsite, which is applied in the field of resource utilization of waste clay, can solve the problems of limited landfill and reclamation area, occupation of land resources, and damage to soil structure, so as to improve disease resistance, germination rate, and durability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

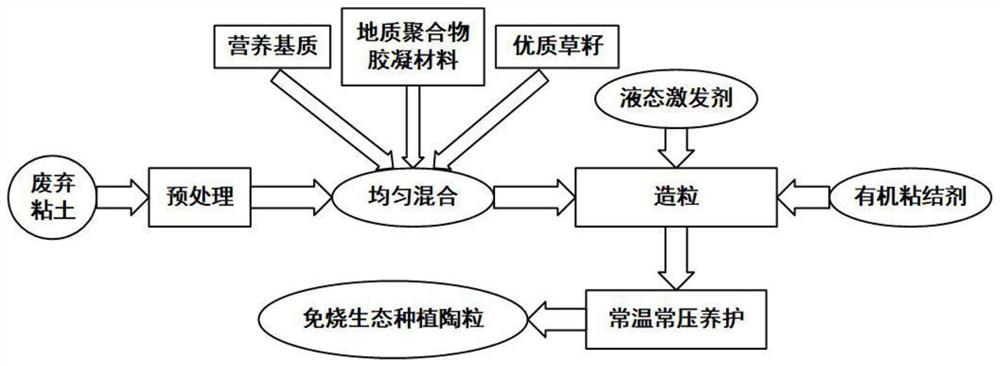

Method used

Image

Examples

Embodiment 1

[0029] Preparation of nutrient matrix: Mix leaf humus, chicken manure and probiotic group liquid with water, stack and ferment for a week, turn over the pile when the central temperature reaches 50-55°C, and continue fermentation, and stop fermentation when the central temperature exceeds 65°C , to obtain the nutrient matrix. Wherein the mass ratio of humus soil and chicken manure is 1:1, and the probiotic group liquid is mixed with lactobacillus, bifidobacteria, bacillus and yeast according to the mass ratio of 1:1:1:1, and the nutrient matrix (leaf humus soil , total amount of chicken manure): probiotics liquid: water = 1:300:150.

[0030] Weigh raw materials: 60 parts of clay, 5 parts of fly ash, 20 parts of fermented leaf humus, chicken manure nutrient matrix (mass ratio 1:1), 17 parts of water, 1 part of water glass, 2 parts of polyvinyl alcohol, Zoysia grass seeds 10 parts.

[0031] Preparation process: water glass and polyvinyl alcohol are dissolved in water for stand...

Embodiment 2

[0035] Preparation of nutrient matrix: mix plant ash, crushed straw, chicken manure and probiotic liquid with water, stack and ferment for a week, turn the pile when the center temperature reaches 50-55°C, and continue fermentation, when the center temperature exceeds 65°C, stop Fermentation to obtain a nutrient substrate. Among them, the mass ratio of plant ash, crushed straw, and chicken manure is 1:1:1, and the probiotic group liquid is mixed with lactobacillus, bifidobacterium, bacillus and yeast according to the mass ratio of 1:1:1:1, and the nutrient matrix ( Total amount of mulch and chicken manure): probiotics liquid: water = 1.5:400:160.

[0036] Weighing raw materials: 65 parts of clay, 3 parts of slag powder, 15 parts of fermented nutrient substrate, 16 parts of water, 2 parts of triethanolamine, 2 parts of vinyl acetate, and 12 parts of tall fescue seeds.

[0037] Preparation process: triethanolamine and vinyl acetate are dissolved in water for standby;

[0038] ...

Embodiment 3

[0041] Preparation of nutrient matrix: mix wheat straw, horse manure and probiotic group liquid with water, pile up and ferment for a week, turn over the pile when the central temperature reaches 50-55°C, and continue fermentation. When the central temperature exceeds 65°C, stop the fermentation to obtain Nutrient matrix. Wherein the mass ratio of wheat straw and horse manure is 1:1, and the probiotic group liquid is mixed with lactobacillus, bifidobacterium, bacillus and yeast according to the mass ratio of 1:1:1:1, and the nutrient matrix (leaf humus, chicken total feces): probiotics liquid: water = 1.5:350:160.

[0042] Weigh raw materials: 60 parts of clay, 3 parts of fly ash, 15 parts of fermented nutrient substrate, 16 parts of water, Na 2 SO 4 2 parts, 2 parts of dextrin, 15 parts of four seasons grass seeds.

[0043] Preparation process: Na 2 SO 4 , dextrin dissolved in water for later use;

[0044] Thoroughly mix clay, fly ash, nutrient matrix and grass seeds to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com