A preparation method of boron-affinity double-recognition molecularly imprinted material

A dual recognition, molecular imprinting technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor method selectivity and low product purity, achieve good acid response, solve complex elution process, and fast adsorption kinetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of graphene oxide (GO)

[0043] 3g of graphite powder and 0.15g of sodium nitrate were added to 30mL of concentrated sulfuric acid and cooled to below 10°C. Secondly, 3g of potassium permanganate was added into the reaction system to stir at 35°C for 1 hour in a 250ml three-neck flask. Subsequently, 138 mL of distilled water was slowly added to the flask until the temperature reached 80 °C. Finally, 30 mL of hydrogen peroxide (30%) was added to the reaction system for 15 min. After that, 200mL of concentrated hydrochloric acid (10%) was added to the mixture at room temperature and washed with distilled water several times, and finally dried at 60°C.

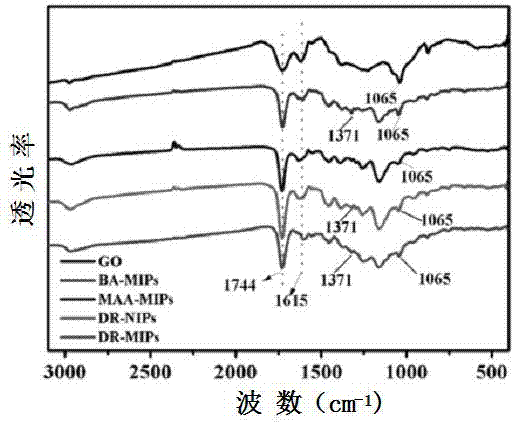

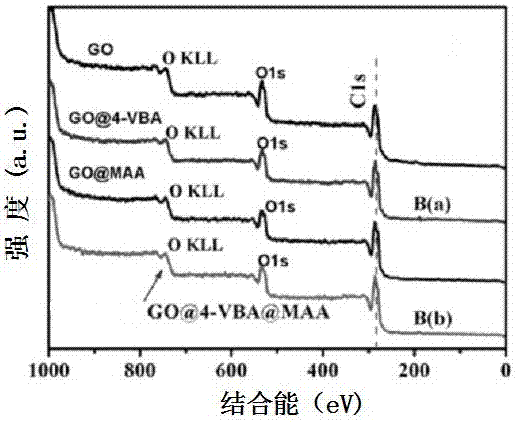

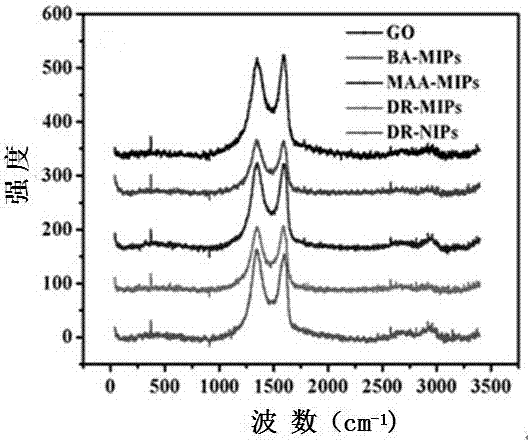

[0044] (2) Preparation of graphene oxide dual surface imprinted nanoparticles (DR-MIPs)

[0045] Wrap the double recognition molecular imprinted layer on the surface of graphene oxide: 100mg graphene oxide (GO), 0.5mmol luteolin (LTL), 5mmol ethylene glycol dimethacrylate (EGDMA), 0.1mmola-methacrylic ac...

Embodiment 2

[0054] (1) Preparation of graphene oxide (GO)

[0055] 3g of graphite powder and 0.6g of sodium nitrate were added to 120mL of concentrated sulfuric acid and cooled to below 10°C. Secondly, 3g of potassium permanganate was added into the reaction system to stir at 35°C for 5 hours in a 250ml three-neck flask. Subsequently, 138 mL of distilled water was slowly added into the flask until the temperature reached 100 °C. Finally, 30 mL of hydrogen peroxide (30%) was added to the reaction system for 15 min. After that, 200mL of concentrated hydrochloric acid (10%) was added to the mixture at room temperature and washed with distilled water several times, and finally dried at 60°C.

[0056] (2) Preparation of graphene oxide dual surface imprinted nanoparticles (DR-MIPs)

[0057] Wrap the double recognition molecular imprinted layer on the surface of graphene oxide: 100mg graphene oxide (GO), 2mmol luteolin (LTL), 12mmol ethylene glycol dimethacrylate (EGDMA), 1mmola-methacrylic a...

Embodiment 3

[0061] (1) Preparation of graphene oxide (GO)

[0062] 3g of graphite powder and 0.5g of sodium nitrate were added to 69mL of concentrated sulfuric acid and cooled to below 10°C. Secondly, 3g of potassium permanganate was added into the reaction system to stir at 35°C for 2 hours in a 250ml three-neck flask. Subsequently, 138 mL of distilled water was slowly added to the flask until the temperature reached 98 °C. Finally, 30 mL of hydrogen peroxide (30%) was added to the reaction system for 15 min. After that, 200mL of concentrated hydrochloric acid (10%) was added to the mixture at room temperature and washed with distilled water several times, and finally dried at 60°C.

[0063] (2) Preparation of graphene oxide dual surface imprinted nanoparticles (DR-MIPs)

[0064] Wrap the double recognition molecular imprinted layer on the surface of graphene oxide: 100mg graphene oxide (GO), 1mmol luteolin (LTL), 8mmol ethylene glycol dimethacrylate (EGDMA), 0.5mmola-methacrylic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com