High-temperature-resistance and high-strength precoated sand and preparation method thereof

A technology of coated sand and high strength, applied in the field of molding materials, can solve the problems of low strength and poor thermal stability of coated sand, and achieve the effects of low expansion rate, long heat resistance time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

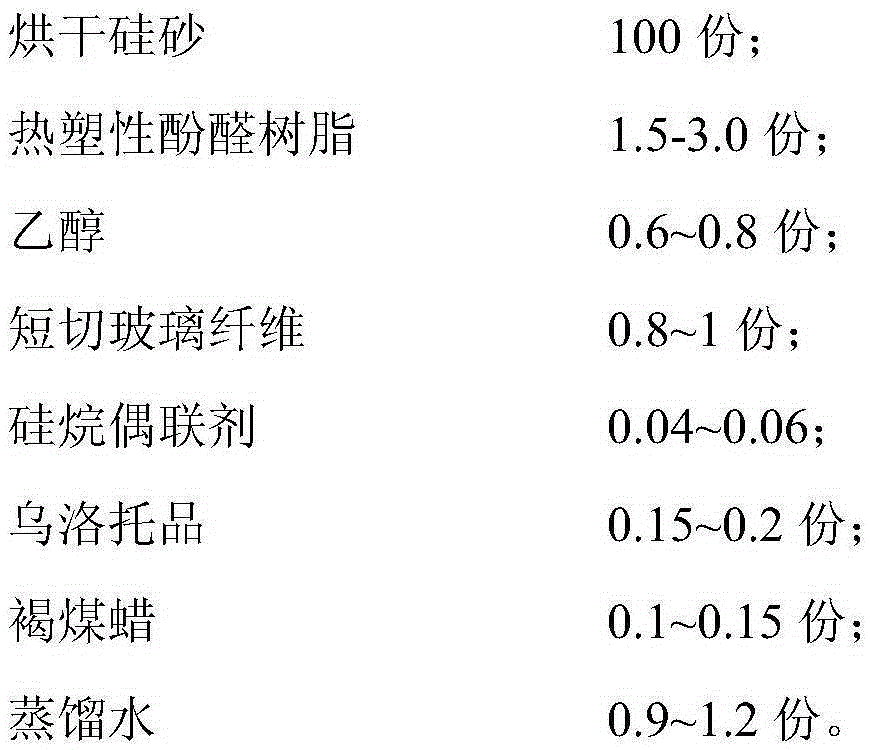

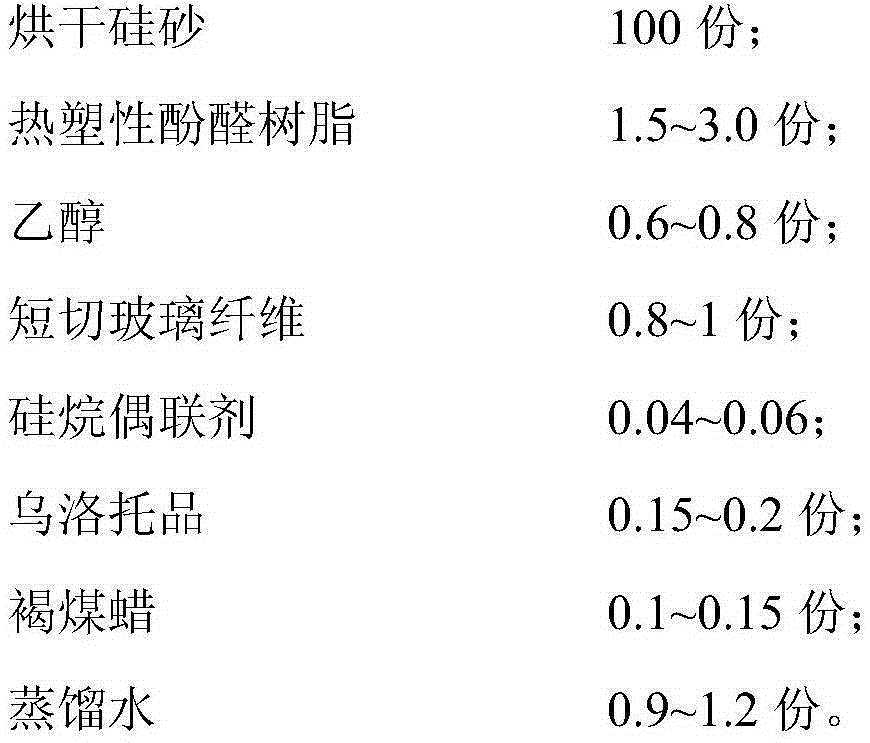

Embodiment 1

[0021] First dissolve 1.1 parts of thermoplastic phenolic resin into solution with 0.6 parts of ethanol, then add 0.8 parts of chopped glass fiber with a length of 0.1mm and 0.04 parts of silane coupling agent to the solution, and simultaneously mix 0.15 parts of urotropine with 1 part Aqueous solution, let the solution stand for 1 hour for later use; then preheat 100 parts of dry sand to 125 ° C, add thermoplastic phenolic resin solution for sand mixing for 60 seconds, then add urotropine aqueous solution for sand mixing for 50 seconds, and finally add 0.12 parts of montan wax Mix sand for 16 seconds, and the above data are the percentage of silica sand. The obtained coated sand is tested with a resin sand high temperature performance tester, and the results are as follows:

[0022] The coated sand produced in this example has a high temperature strength of 0.15 MPa at a high temperature of 1200° C. for 6 seconds, good high temperature stability, and a high temperature linear...

Embodiment 2

[0024] First dissolve 1.2 parts of thermoplastic phenolic resin into solution with 0.7 parts of ethanol, then add 0.9 parts of chopped glass fiber with a length of 0.2 mm and 0.05 parts of silane coupling agent to the solution, and let the solution stand for 1.5 hours for later use; at the same time, add 0.18 1 part of urotropine and 1.1 parts of aqueous solution, then preheat 100 parts of dried sand to 130°C, add thermoplastic phenolic resin solution for sand mixing for 65 seconds, then add urotropine aqueous solution for sand mixing for 53 seconds, and finally add 0.13 parts of montan wax Mix sand for 18 seconds, and the above data are the percentage of silica sand. The prepared coated sand was subjected to normal temperature tensile strength test and high temperature performance test, the results are as follows:

[0025] The normal temperature tensile strength of the coated sand produced in this example reaches 3.5 MPa, the high temperature strength at 1200° C. for 6 second...

Embodiment 3

[0027] First dissolve 1.3 parts of thermoplastic phenolic resin into solution with 0.8 parts of ethanol, then add 1 part of chopped glass fiber with a length of 0.3 mm and 0.06 parts of silane coupling agent to the solution, and let the solution stand for 2 hours for later use; 1 part of urotropine and 1.2 parts of aqueous solution, then preheat 100 parts of dried sand to 132°C, add thermoplastic phenolic resin solution for sand mixing for 70s, then add urotropine aqueous solution for sand mixing for 54s, and finally add 0.15 parts of montan wax Just mix sand for 20 seconds, and the above data are the percentage of silica sand. The obtained coated sand was tested with resin sand normal temperature flexural strength and high temperature performance tester, the results are as follows:

[0028] The coated sand produced in this example has a high temperature strength of 0.180 MPa at a high temperature of 1200° C. for 6 seconds, good high temperature stability, and a high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com