Sludge special-conveying system and method

A sludge and sludge treatment technology, applied in transportation and packaging, tilt-bearing vehicles, garbage receptacles, etc., can solve problems such as traffic hazards, sludge dumping, pollution, etc. The effect of environmental protection and reduction of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

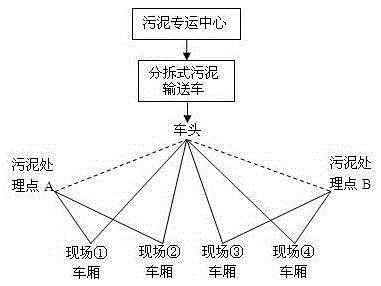

[0023] like figure 1 As shown, a sludge transport system includes a sludge transport center, a split sludge transport vehicle, a split sludge transport vehicle head, a sludge dehydration workshop site in a sewage treatment plant, and a split sludge transport vehicle Compartments and sludge treatment points; the sludge dewatering workshop of the sewage treatment plant has on-site ① compartment, on-site ② compartment, on-site ③ compartment, on-site ④ compartment, or more, and each sludge dewatering workshop site is equipped with at least two splits One of the compartments of the type sludge conveying vehicle, one of which is in the working state of filling sludge to play a storage function, and the other is in the state of being ready to load sludge. The sludge treatment points include sludge treatment point A, sludge treatment point B, or More, the sludge transport center adopts the head of the detachable sludge conveying vehicle, which pulls the compartment of the detached slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com