Preparation method of filament-like W18O49 material

A W18O49, filamentous technology, applied in the field of preparation of filamentous W18O49 materials, can solve the problems of complex methods, low chemical purity, and uneven morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Add 0.7931gWCl 6 Add it to 40mL of absolute ethanol to prepare a 0.05mol / L solution A;

[0025] 2) Add 0.5390g analytically pure octadecylamine (CH 3 (CH 2 ) 16 CH 2 NH 2 ), to obtain solution B;

[0026] 3) Seal solution B with a plastic wrap to avoid contact with the air, first use magnetic stirring for 20 minutes, and then ultrasonic (60 Hz) treatment for 30 minutes to obtain solution C;

[0027] 4) Add solution C to a 100mL polytetrafluoroethylene-lined autoclave with a volume filling ratio of 40%, then seal the autoclave, and react in a homogeneous reactor at 160°C for 24h Cool to room temperature with the furnace, centrifuge with absolute ethanol, wash 3 times, and dry in a vacuum oven at 60°C for 3 hours to obtain filamentous W 18 o 49 Material.

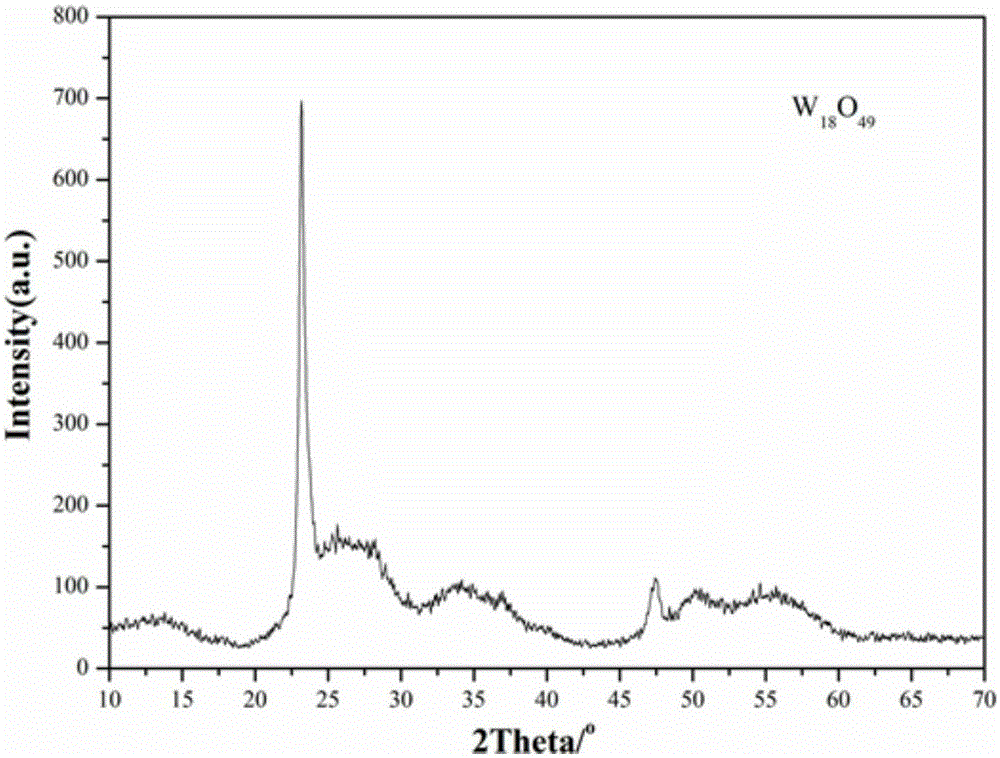

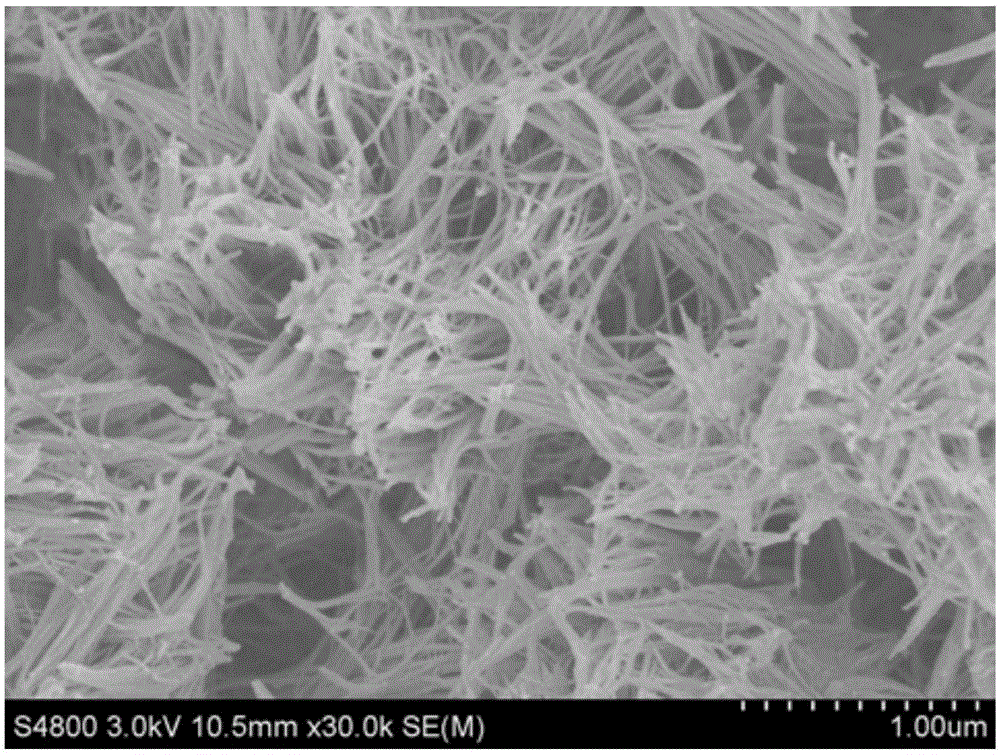

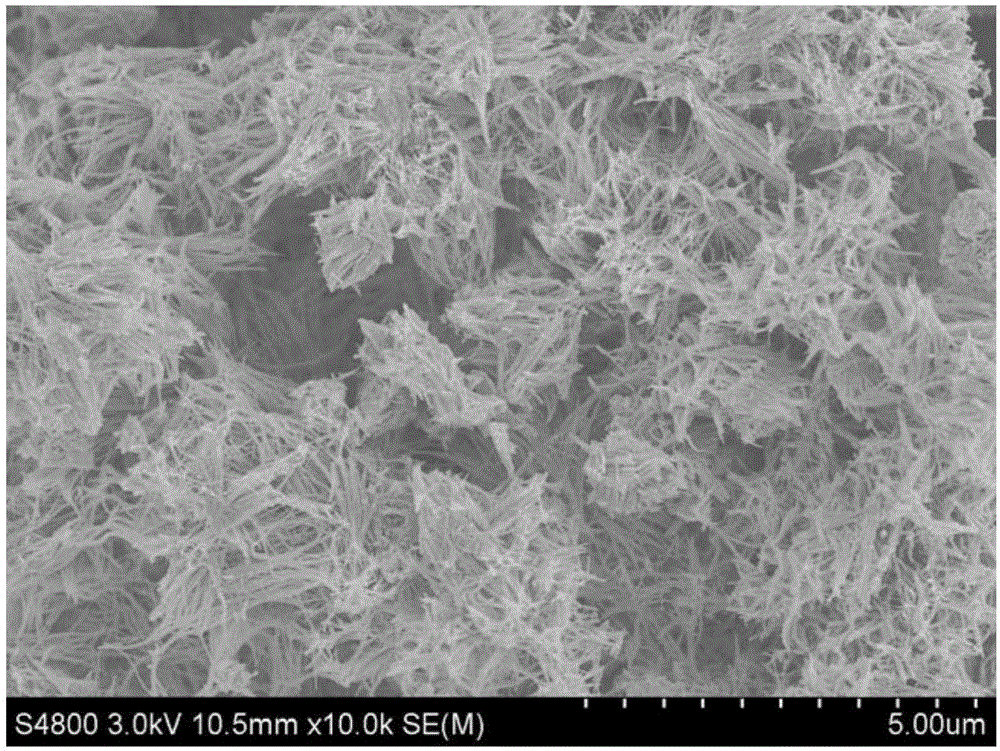

[0028] Depend on figure 1 It can be seen that: the W of the pure phase of the product prepared by the present invention 18 o 49 Material. Depend on figure 2 It can be seen that the W obtained by the pr...

Embodiment 2

[0031] 1) Add 0.9914gWCl 6 Add it into 50mL of absolute ethanol to prepare 0.06mol / L solution A;

[0032] 2) Add 0.6468g analytically pure octadecylamine (CH 3 (CH 2 ) 16 CH 2 NH 2), to obtain solution B;

[0033] 3) Seal solution B with plastic wrap to avoid contact with air, first use magnetic stirring for 40 minutes, and then ultrasonic (60 Hz) treatment for 20 minutes to obtain solution C;

[0034] 4) Add solution C to a 100mL polytetrafluoroethylene-lined autoclave with a volume filling ratio of 40%, then seal the autoclave and react in a homogeneous reactor at 150°C for 18 hours Cool to room temperature with the furnace, centrifuge with absolute ethanol, wash 3 times, and dry in a vacuum oven at 60°C for 3 hours to obtain filamentous W 18 o 49 Material.

[0035] The filamentous W obtained in this example 18 o 49 A single length of about 1 ~ 1.5μm.

Embodiment 3

[0037] 1) 1.0259gWCl 6 Add it to 60mL of absolute ethanol to prepare a 0.08mol / L solution A;

[0038] 2) Add 2.5870g analytically pure octadecylamine (CH 3 (CH 2 ) 16 CH 2 NH 2 ), to obtain solution B;

[0039] 3) Seal solution B with a plastic wrap to avoid contact with the air, first use magnetic stirring for 20 minutes, and then ultrasonic (60 Hz) treatment for 30 minutes to obtain solution C;

[0040] 4) Add solution C to a 100mL polytetrafluoroethylene-lined autoclave with a volume filling ratio of 60%, then seal the autoclave, and react in a homogeneous reactor at 170°C for 18 hours Cool to room temperature with the furnace, centrifuge with absolute ethanol, wash 3 times, and dry in a vacuum oven at 60°C for 3 hours to obtain filamentous W 18 o 49 Material.

[0041] The filamentous W obtained in this example 18 o 49 A single length of about 1.3 ~ 1.8μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com