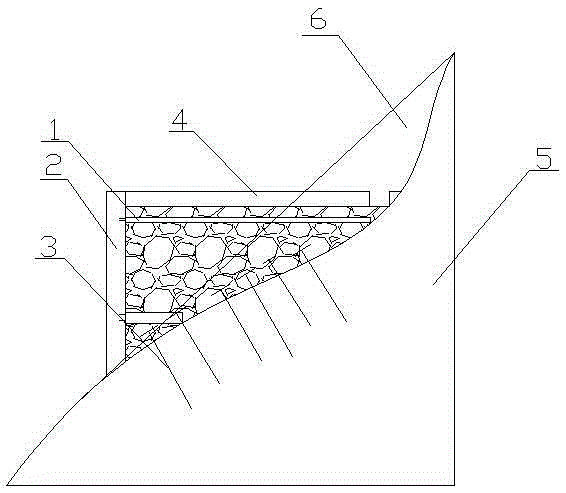

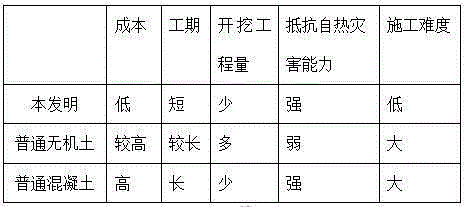

Lightweight foam soil applied to roadbed filling of mountainous-area steep road section

A lightweight foam and subgrade technology, applied in the field of lightweight foam soil, can solve the problems of low utilization rate of excavation surface, high support cost, and reduced excavation volume, achieving uniform and independent hole diameter, small settlement, and reduced effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The present invention is applied to the light soil for the replacement of special roadbeds in subways, and is made of the following raw materials in parts by weight: 120 parts of cement, 5 parts of silica fume powder, 5 parts of diatomaceous earth, 60 parts of water, 2 parts of water reducing agent, 1 part of early strength agent, 5 parts of synthetic fiber, 5 parts of foaming agent, 2 parts of microfoaming agent.

[0055] The cement is preferably PO42.5 Portland cement.

[0056] The water reducer is preferably a polycarboxylate water reducer.

[0057] The early strengthening agent is calcium chloride.

[0058] The foaming agent is preferably a HT composite foaming agent, and its components include animal protein and vegetable protein, and one or more of rosin soap, hydrogen peroxide and aluminum powder.

[0059] The microfoam is preferably prepared by diluting the foaming agent with water at a ratio of 1:2000 and microfoaming through a plunger pump.

[0060] The syn...

Embodiment 2

[0066] The present invention is applied to the lightweight soil for the replacement of special roadbeds in subways. It is made of the following components by weight: 200 parts of cement, 35 parts of silica fume powder, 55 parts of diatomaceous earth, 150 parts of water, 20 parts of water reducing agent, 3 parts of early strength agent, 20 parts of synthetic fiber, 10 parts of foaming agent, and 15 parts of microfoaming agent.

[0067] The cement is preferably PO52.5R Portland cement.

[0068] The water reducer is preferably a polycarboxylate water reducer.

[0069] The early strengthening agent is sodium chloride.

[0070] The foaming agent is preferably a HT composite foaming agent, and its components include animal protein and vegetable protein, and one or more of rosin soap, hydrogen peroxide and aluminum powder.

[0071] The microfoam is preferably prepared by diluting the foaming agent with water at a ratio of 1:2000 and microfoaming through a plunger pump.

[0072] Th...

Embodiment 3

[0078] The present invention is applied to the lightweight soil for the replacement of special roadbeds in subways, and is made of the following raw materials in parts by weight: 150 parts of cement, 20 parts of silica fume powder, 30 parts of diatomite, 90 parts of water, 15 parts of water reducing agent, 2 parts of early strength agent, 15 parts of synthetic fiber, 8 parts of foaming agent, and 9 parts of microfoaming agent.

[0079] The cement is preferably PO42.5 Portland cement.

[0080] The water reducer is preferably a polycarboxylate water reducer.

[0081] The early strengthening agent is calcium chloride.

[0082] The foaming agent is preferably a HT composite foaming agent, and its components include animal protein and vegetable protein, and one or more of rosin soap, hydrogen peroxide and aluminum powder.

[0083] The microfoam is preferably prepared by diluting the foaming agent with water at a ratio of 1:2000 and microfoaming through a plunger pump.

[0084] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com