Method for preparation of long-chain alkane from unsaturated fatty acid at zero hydrogen consumption

A technology of unsaturated fatty acids and long-chain alkanes, which is applied in the field of preparation of long-chain alkanes, can solve the problems of low efficiency, low yield of alkanes or alkenes, etc., and achieve the effects of low energy consumption, low catalyst cost, and zero hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

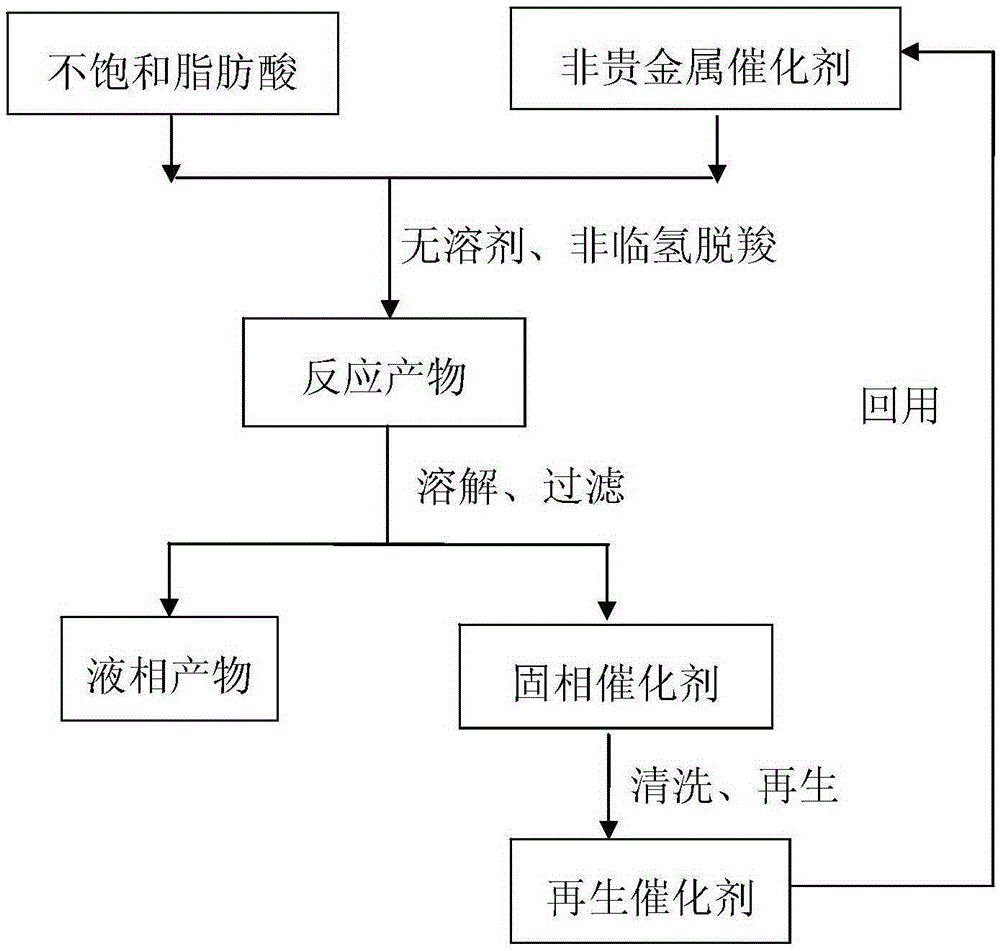

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 200g hexadecenoic acid and 10g10%Cu-30%Ni / ZrO in a 500mL batch autoclave 2 Catalyst, start stirring, heat up to 350 ℃ and react for 5 hours; after the reaction is completed, the reaction product is cooled, dissolved with acetone, and filtered; the liquid phase product is analyzed by GC-FID after constant volume with acetone, and the molar yield of long-chain alkanes is calculated as 61.2%.

Embodiment 2

[0030] Add 200g of erucic acid and 16.7g of 20%Zu-20%Co / ZrO in a 500mL batch autoclave 2 Catalyst, start stirring, heat up to 330 ℃ and react for 4 hours; after the reaction is completed, the reaction product is cooled, dissolved and filtered with acetone; the liquid phase product is analyzed by GC-FID after constant volume with acetone, and the molar yield of long-chain alkanes is calculated as 26.4%.

Embodiment 3

[0032] Add 200g of eicosenoic acid and 25g of 10%Cu-40%Ni / ZSM-5 catalyst into a 500mL intermittent high-pressure reactor, start stirring, and raise the temperature to 370°C for 3 hours; after the reaction is completed, the reaction product is cooled and dissolved in acetone , filtration; the liquid phase product is analyzed by GC-FID after constant volume with acetone, and the molar yield of long-chain alkanes calculated is 60.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com