A method for knocking out PCKA to promote the synthesis of acetylglucosamine by Bacillus subtilis

A technology of Bacillus subtilis and acetamido, applied in the field of genetic engineering, can solve problems such as low yield of acetylglucosamine, and achieve the effects of reducing the generation of by-products, having good application prospects and improving accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

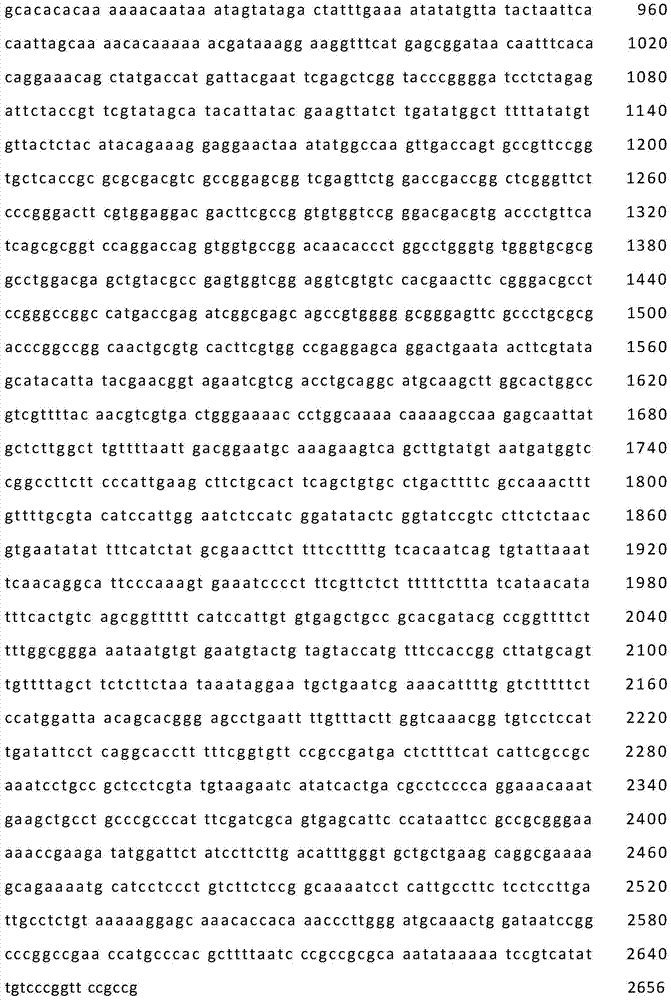

[0024] Example 1: Knockout of the gene pckA encoding phosphoenolpyruvate carboxylase

[0025] According to the upstream and downstream sequences of the phosphoenolpyruvate carboxylase encoding gene pckA of Bacillus subtilis (Bacillus subtilis 168 purchased from the American Type Microorganism Collection, ATCC No.27370) published on NCBI, and the bleomycin resistance For the sequence of the gene, a knockout frame whose sequence is shown in SEQ ID NO.1 is constructed.

[0026] Transform the constructed knockout frame into recombinant Bacillus subtilis BSGNK-P xylA -glmS -P 43-GNA1 (that is, the recombinant Bacillus subtilis BSGNK constructed in patent application 201510394205.7), through bleomycin resistance plate screening and colony PCR verification, confirmed that the knockout of phosphoenolpyruvate carboxylase (pckA) was successful, The recombinant Bacillus subtilis BSGNKA was obtained. Recombinant Bacillus subtilis BSGNK-P xylA -glmS -P 43 -GNA1 is BSGN6-P constructed ...

Embodiment 2

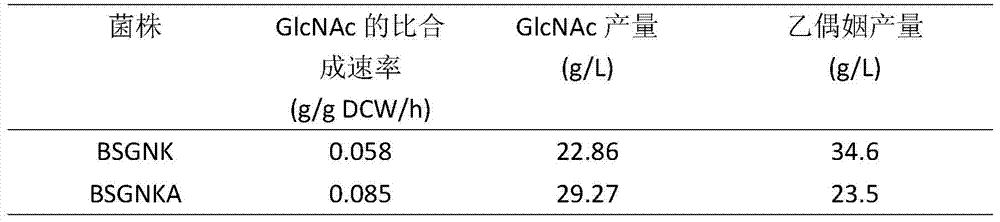

[0027] Example 2: Fermentative production of acetylglucosamine

[0028] The seeds cultivated at 37° C. and 220 rpm for 8 hours were transferred to the fermentation medium at an inoculum size of 3%, and cultured in a 3L fermenter at 35-37° C. and 600-800 rpm for 52-72 hours. When fermented for 52 hours, the content of acetylglucosamine in the fermentation supernatant reached 29.27g / L, which was different from that of the control bacterium BSGNK-P xylA -glmS -P 43 - Compared with GNA1, it increased by 28.1% (results are shown in Table 1), realizing the increase of the extracellular production of acetylglucosamine in recombinant Bacillus subtilis. In addition, the specific synthesis rate of acetylglucosamine of the BSGNKA bacterial strain of the present invention reaches 0.085g / g DCW / h, which is 46.5% higher than that of the control bacterial strain BSGNK. Simultaneously, the output of the by-product acetoin of the bacterial strain of the present invention is 23.5g / L, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com