High-precision portable optical surface three-dimensional topography online detector

A three-dimensional topography and optical surface technology, which is used in high-precision online batch detection devices and ultra-precision machining components in the field of fast processing, can solve problems such as the inability to achieve surface detection of large-diameter optical components, the limitation of online detection by instruments, and the lack of structural stability. , to achieve the effect of superior anti-vibration performance, easy operation and reduced workpiece inspection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

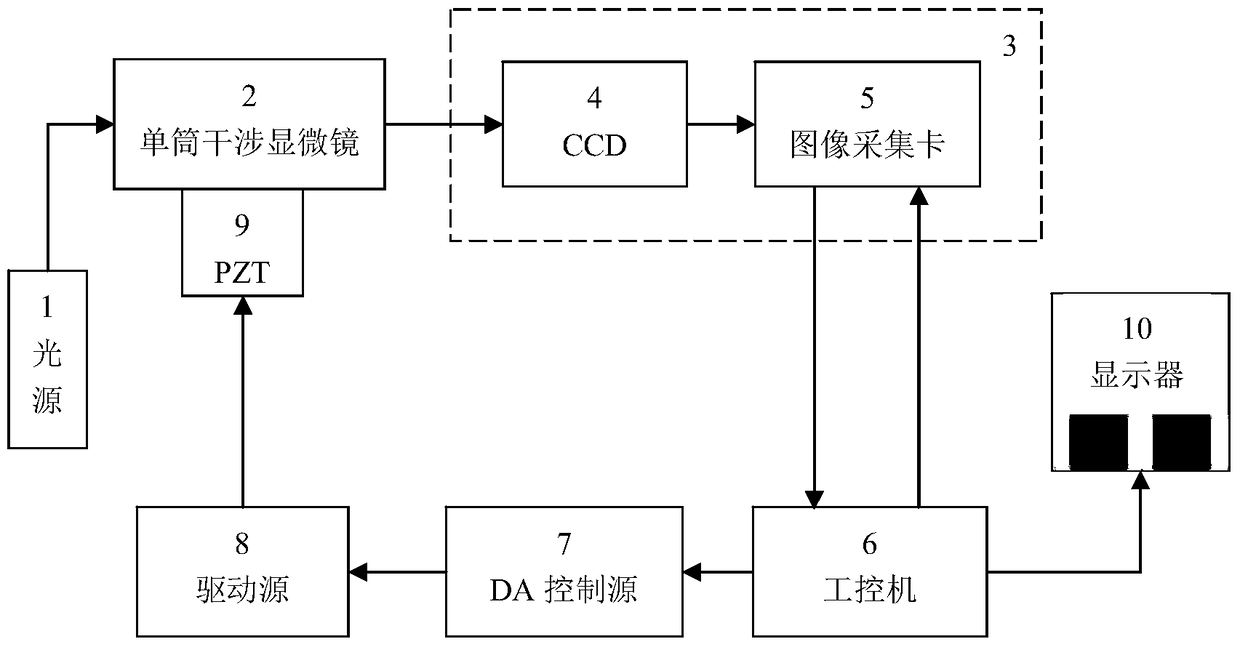

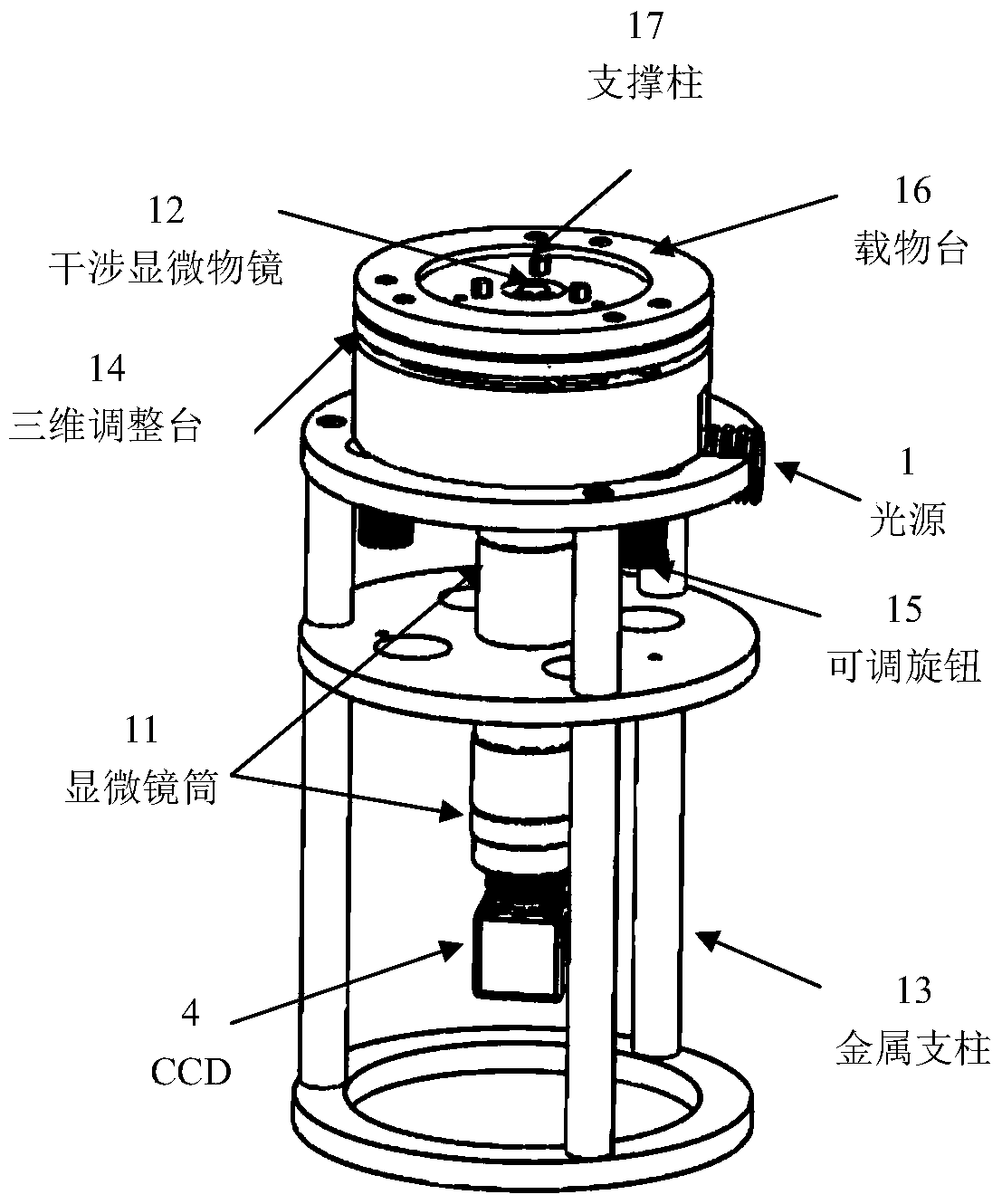

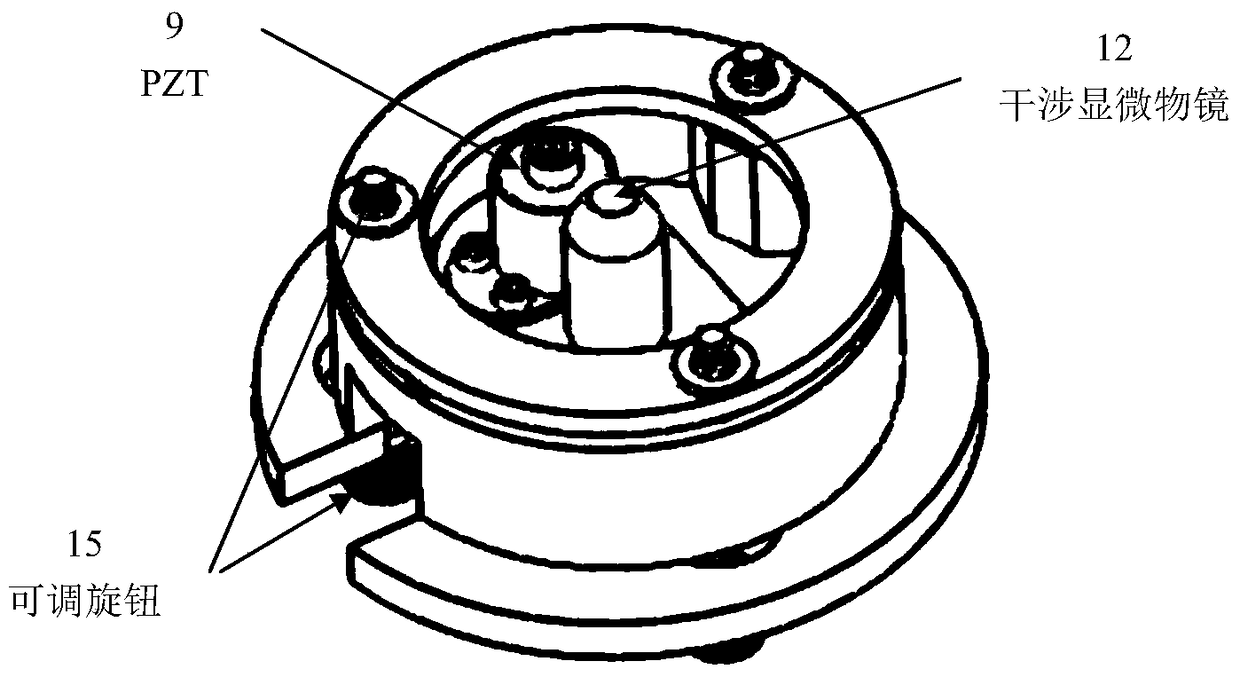

[0013] combine figure 1 , figure 2 , image 3 , the high-precision portable optical surface three-dimensional topography online detector described in the present invention mainly includes a light source 1, a monocular interference microscope 2 (consisting of a microscope tube 11 and an interference microscope objective lens 12), an image acquisition system 3, and an industrial computer 6. Control source 7, drive source 8, PZT9 phase shifter and display 10. The PZT phase shifter 9 is located between the microscope barrel 11 and the interference microscope objective lens 12, and is driven by the drive source 8 to move the microscope objective lens. The image acquisition system 3 is composed of a CCD camera 4 and an image acquisition card 5. The output of the CCD camera 4 end is connected with the image acquisition card 5, the image acquisition card 5 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com