Printed AM-QDLED and preparation method thereof

A technology of AM-QDLED and manufacturing method, applied in the field of light-emitting devices, can solve problems such as uneven film formation of AM-QDLED, and achieve the effects of improving device performance, flat uniformity, and increasing wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

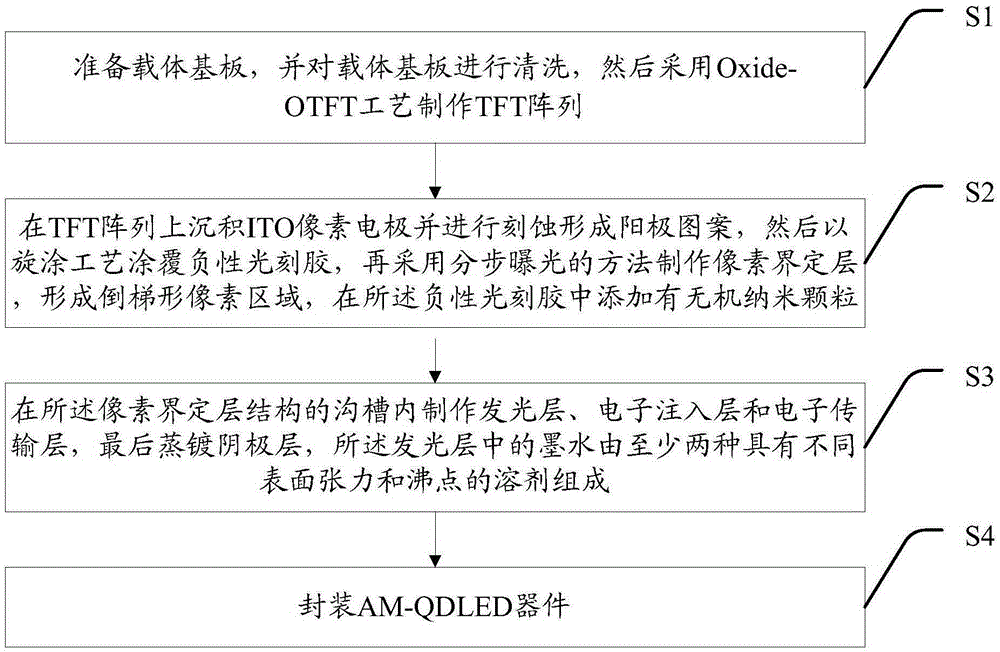

[0042] The present invention provides a printed AM-QD LED and its manufacturing method. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

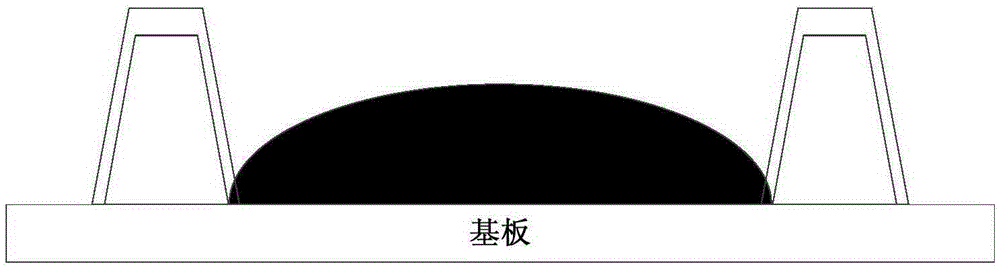

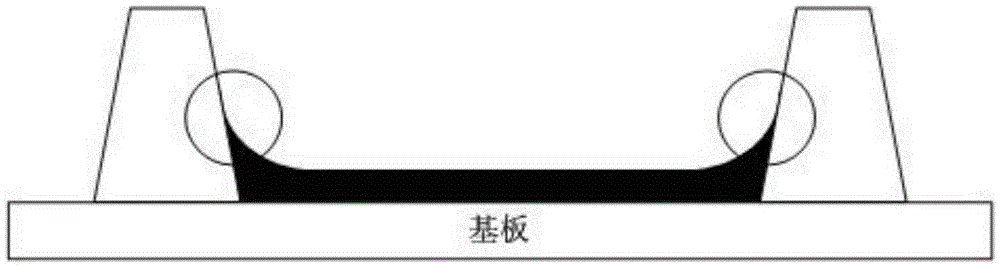

[0043] Based on the existing printing system, process and equipment structure, the present invention adjusts the fluidity and film-forming properties of the ink in the pixel defining layer through two key steps to produce printed AM-QD LED devices. One: By adding (insoluble) inorganic nanoparticles to the negative photoresist and making them uniformly distributed, the roughness of the inner slope of the pixel defining layer increases after exposure, development and curing to form the Wenzel effect, so as to enlarge the ink and the pixel defining layer Affinity and hydrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com