Equipment and process for condensing and collecting steam and waste gas at tail end of multi-grade flash evaporation device

A flash evaporation device and steam technology, which can be used in steam condensation, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as air pollution and harm the environment, and achieve the effect of protecting the environment and avoiding air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

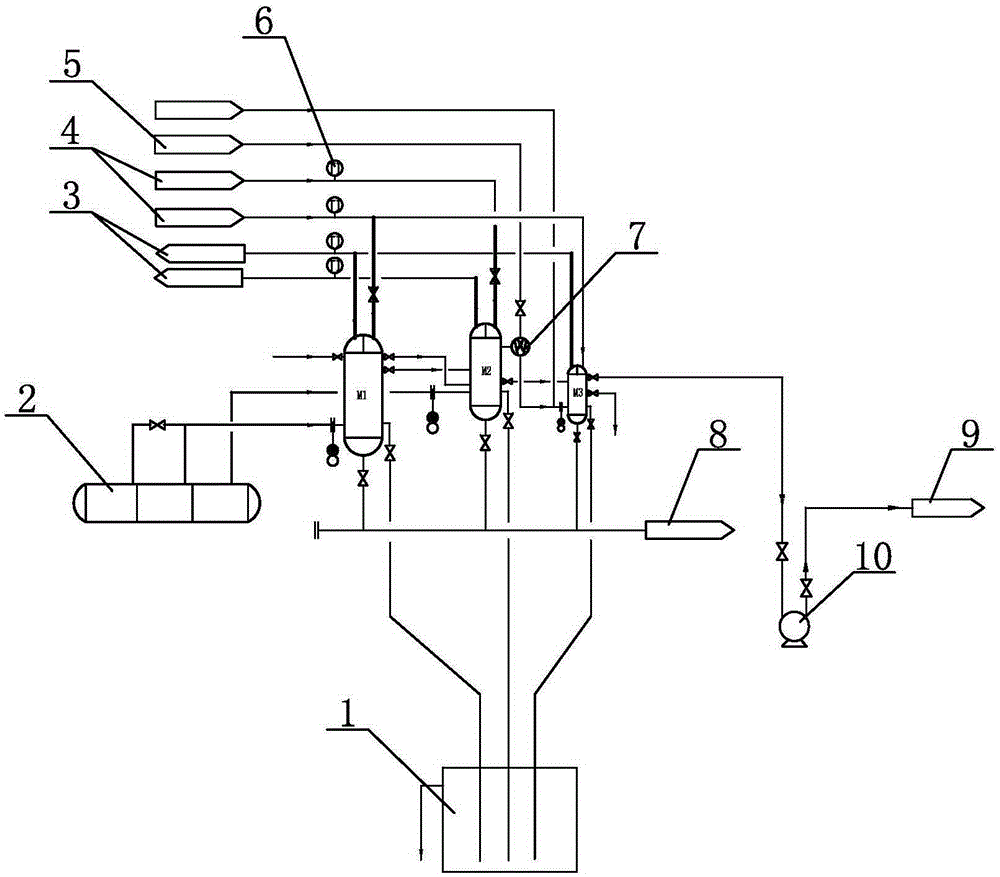

[0017] Such as figure 1 As shown, the equipment for condensing and collecting steam and exhaust gas at the end of the multi-stage flash evaporator includes a multi-stage flash evaporator 2, and the end of the multi-stage flash evaporator 2 is connected to the first-level indirect condenser M1 and the second-level condenser M2 through pipelines, The first-stage indirect condenser M1 and the second-stage condenser M2 are connected through pipelines, the second-stage condenser M2 is connected to the steam jet pump 7 and the third-stage condenser M3 through the pipeline in turn, the steam jet pump 7 is connected to the steam source 5, and the third-stage condensing The device M3 is sequentially connected to the vacuum pump 10 and the waste gas treatment system 9 through the pipeline;

[0018] The first-stage indirect condenser M1, the second-stage condenser M2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com