A manufacturing system and method for three-dimensional molding of absorbing materials

A wave-absorbing material and three-dimensional molding technology, applied in the direction of additive manufacturing, processing and manufacturing, manufacturing tools, etc., can solve the problems of poor designability, single product structure, high proportion of wave-absorbing particles, etc., and achieve the effect of improving designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

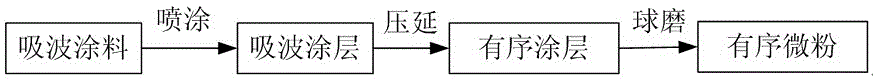

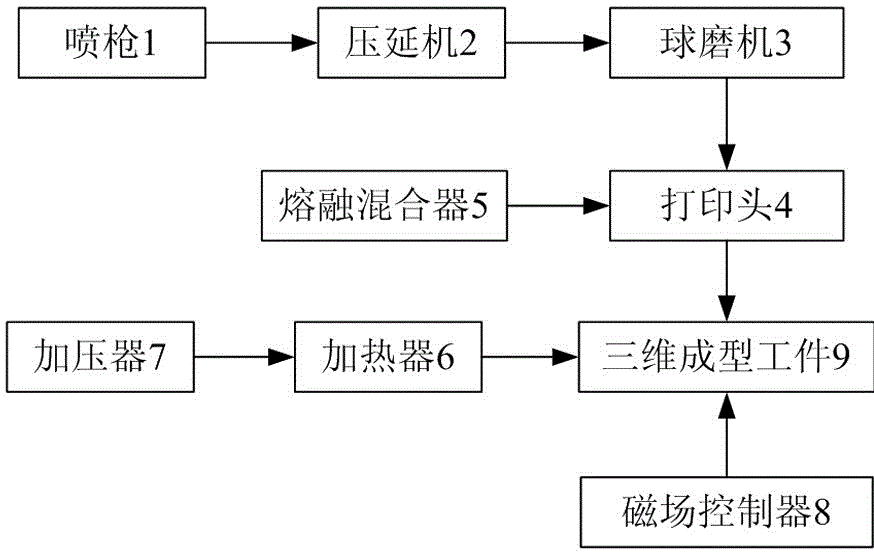

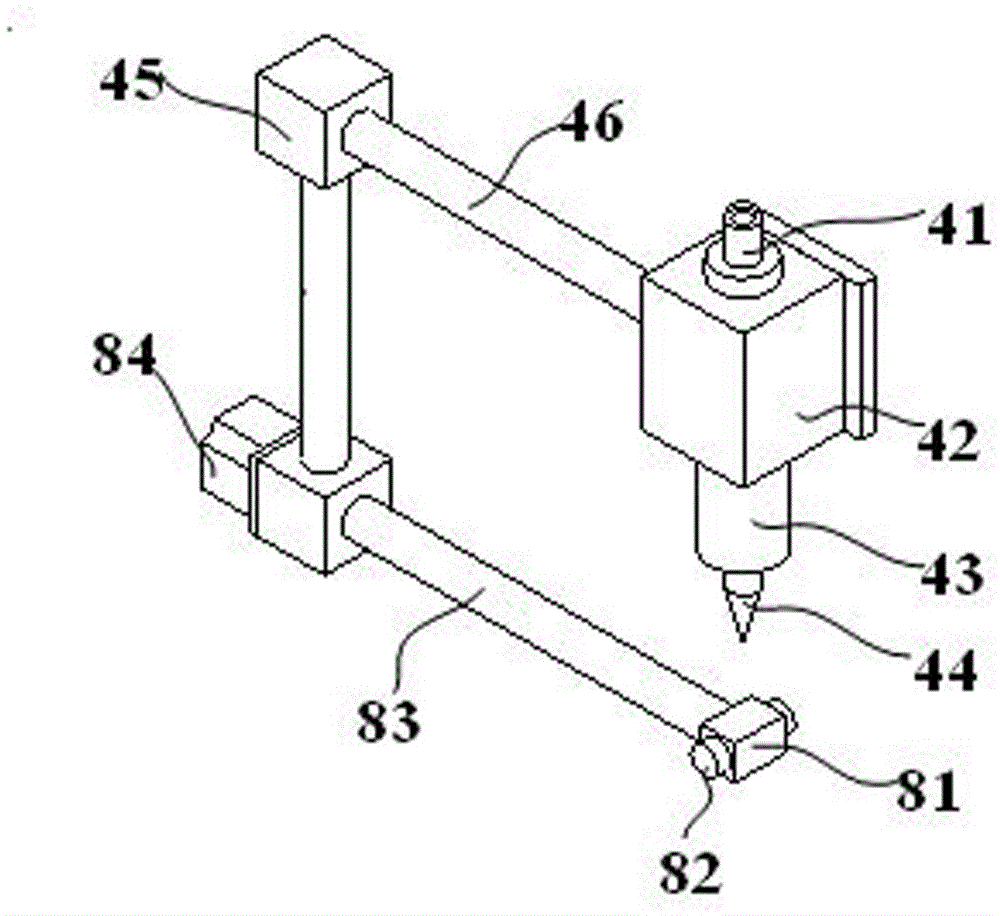

[0051] The manufacturing system and method of three-dimensionally shaped electromagnetic materials provided by the present invention include:

[0052] First, use absolute ethanol to clean the surface of the sample to be sprayed, mix epoxy resin and diluent, add white carbon black and mix evenly, then gradually add microwave-absorbing micropowder, stir the mixed material evenly with a disperser, and take out the dispersed Add the coating to the spray gun 1, use the spray gun 1 to spray the wave-absorbing coating, the diameter of the spray gun 1 is 1.5mm, and the pressure is 0.2MPa. The thickness is about 0.4mm.

[0053] When the wave-absorbing material on the plate is semi-cured, take out the surface of the wave-absorbing material, test its thickness, and then stick a layer of PE film on its surface, the film thickness range is 0.1mm, and use the calender 2 to carry out the calendering process. The distance between the two rollers of the calender 2 can gradually be 0.6 times t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com