A composite treatment system and method for oilfield produced water

A composite treatment and water production technology, applied in the field of water treatment, can solve the problems of large fluctuations in effluent water quality, long process routes, and many treatment equipments, and achieve the effects of low environmental pollution, simple operation and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will now be further described in conjunction with the drawings and embodiments.

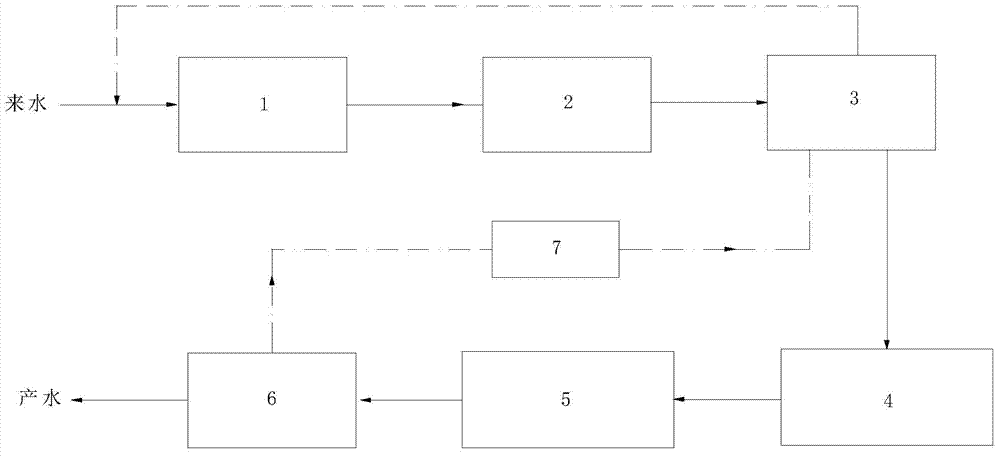

[0022] Depend on figure 1 It can be seen that the oilfield produced water composite treatment system is composed of an oil-water separator 1, a buffer water tank 2, an inorganic carbon film processor 3, a water storage tank 4, a filter adsorption processor 5, a backwash pump 7 and a purified water tank 6 through pipelines. constitute.

[0023] Among them: the oil-water separator 1 belongs to the pretreatment unit, which can be a cyclone or an inclined plate degreaser or a three-phase separator, which is a commonly used equipment. The pipeline is connected, and the water outlet of this oil-water separator 1 is communicated with the water inlet of buffer water tank 2 through pipeline, and the water outlet of buffer water tank 2 is communicated with the water inlet of inorganic carbon membrane processor 3 through pipeline, and the filtration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com