Chlorinated polyvinyl chloride tube stock and preparation method thereof

A technology of chlorinated polyvinyl chloride and chlorinated polyethylene, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problem that it is difficult to improve the performance indicators of CPVC products at the same time, and achieve product qualification rate and productivity improvement, corrosion resistance. Good performance and the effect of optimizing the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

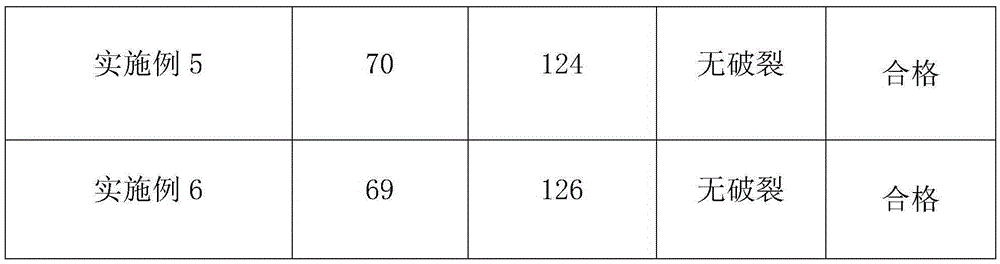

Examples

Embodiment 1

[0021] A chlorinated polyvinyl chloride pipe, which is composed of the following raw materials in parts by weight: 75 parts of CPVC resin, 50 parts of PVC resin, 25 parts of light calcium carbonate, 12.5 parts of MBS resin, 8 parts of heat stabilizer, and 1 part of lubricant , 5 parts of chlorinated polyethylene, 2 parts of ACR processing aid and 0.5 parts of molybdenum chrome red.

[0022] In this embodiment, the chlorine content in the CPVC resin is 60%.

[0023] In this embodiment, the lubricant is oxidized polyethylene wax.

[0024] A preparation method of chlorinated polyvinyl chloride pipe, comprising the following steps:

[0025] (1) Take each raw material according to the formula, put CPVC resin, PVC resin, light calcium carbonate, MBS resin, heat stabilizer, lubricant, chlorinated polyethylene, ACR processing aid and molybdenum chrome red in a high-speed mixer Mix well at 102°C and keep in this temperature range for 5-10 minutes;

[0026] (2) After the above mixtur...

Embodiment 2

[0033] A chlorinated polyvinyl chloride pipe, which is composed of the following raw materials in parts by weight: 75 parts of CPVC resin, 50 parts of PVC resin, 25 parts of light calcium carbonate, 13 parts of MBS resin, 9 parts of heat stabilizer, and 1 part of lubricant , 6 parts of chlorinated polyethylene, 3 parts of ACR processing aid and 0.8 parts of molybdenum red.

[0034] In this embodiment, the chlorine content in the CPVC resin is 60%.

[0035] In this embodiment, the lubricant is oxidized polyethylene wax.

[0036] A preparation method of chlorinated polyvinyl chloride pipe, comprising the following steps:

[0037] (1) Take each raw material according to the formula, put CPVC resin, PVC resin, light calcium carbonate, MBS resin, heat stabilizer, lubricant, chlorinated polyethylene, ACR processing aid and molybdenum chrome red in a high-speed mixer Mix well at 104°C and keep in this temperature range for 5-10 minutes;

[0038] (2) After the above mixture is stir...

Embodiment 3

[0044] A chlorinated polyvinyl chloride pipe, characterized in that it consists of the following raw materials in parts by weight: 75 parts of CPVC resin, 50 parts of PVC resin, 25 parts of light calcium carbonate, 123 parts of MBS resin, 9 parts of heat stabilizer, 1 part of lubricant, 8 parts of chlorinated polyethylene, 3 parts of ACR processing aid and 0.6 part of molybdenum red.

[0045] In this embodiment, the chlorine content in the CPVC resin is 60%.

[0046] In this embodiment, the lubricant is polyethylene wax.

[0047] A preparation method of chlorinated polyvinyl chloride pipe, comprising the following steps:

[0048](1) Take each raw material according to the formula, put CPVC resin, PVC resin, light calcium carbonate, MBS resin, heat stabilizer, lubricant, chlorinated polyethylene, ACR processing aid and molybdenum chrome red in a high-speed mixer Mix well at 105°C and keep in this temperature range for 5-10 minutes;

[0049] (2) After the above mixture is sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com