Sludge splitting and gasifying method

A technology of sludge cracking and cracking gas, which is applied in the field of sludge treatment, can solve the problems of difficult secondary pollution control of flue gas, low degree of sludge resource utilization, etc., to avoid corrosion of equipment, high cracking efficiency, and fast reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

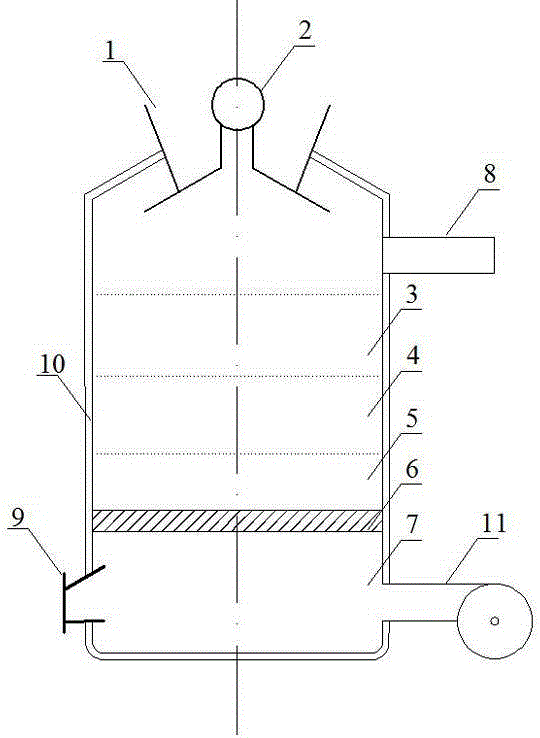

[0043] The sludge cracking and gasification device is provided with a shell 10 on the outside, a sludge feed port 1 is provided on the top of the shell 10, and a drying chamber 3, a pyrolysis chamber 4, an oxidation Room 5 and Ash Room 7.

[0044]The shell 10 is in the shape of an upright barrel, the inner wall of the shell 10 is made of steel plate lined with refractory bricks or refractory cement, and the surface is covered with thermal insulation materials. The sludge feed port 1 is provided with a feed valve 2; the sludge feed port 1 is funnel-shaped, and is closely matched with the feed valve 2 to form a seal to prevent cracking gas from escaping. The upper part of the drying chamber 3 is provided with a pyrolysis gas outlet pipe 8 . The side wall of the ash chamber 7 is provided with a slag outlet 9 and a gasification medium introduction pipe 11 . A grate 6 is arranged between the oxidation chamber 5 and the ash chamber 7 . The grate 6 is made of refractory material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com