Pulverized coal combustion system with porous wall wind coupled air classification

A technology of air classification and pulverized coal combustion, applied in burners, combustion chambers, combustion methods, etc., can solve the problems of high temperature corrosion of water-cooled walls, aggravated heat absorption deviation of heating surfaces, safety accidents, etc., to prevent high temperature corrosion and eliminate absorption. Thermal deviation, contamination reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

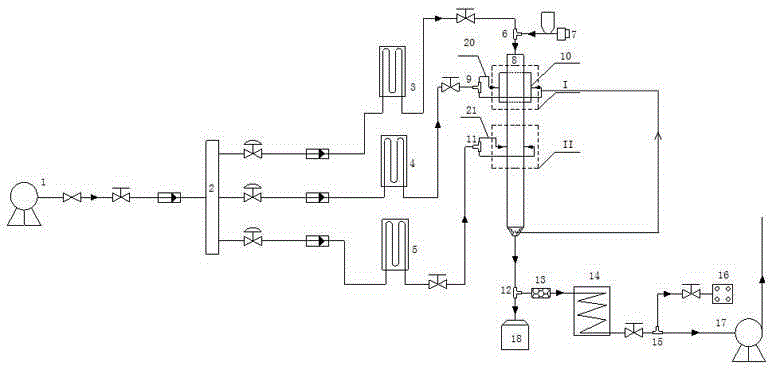

[0012] refer to figure 1 , the pulverized coal combustion system with porous wall wind coupling air staging, including air compressor 1, air distribution box 2, first air preheater 3, second air preheater 4, third air preheater 5, first Three-way joint 6, powder feeder 7, porous wall coupled air classification combustion reactor 8, second three-way joint 9, air chamber 10, third three-way joint 11, fourth three-way joint 12, pipeline filter 13, Flue gas cooler 14, fifth tee joint 15, flue gas analyzer 16, induced draft fan 17, ash pool 18. The outlet of blower 1 is connected to the inlet of air distribution box 2 after passing through the pressure reducing valve, stop valve and air flow meter; the outlet of air distribution box 2 is three air branches, and the first branch passes through the regulating valve and air flow on the branch. After the flow meter, it is connected to the inlet of the first air preheater 3, and the outlet of the first air preheater 3 is connected to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com