Hydrate/ice-containing low-temperature stratum well cementation simulation experiment reaction kettle

A hydrate-containing, simulated experiment technology, applied in chemical/physical/physicochemical processes, material inspection products, chemical/physical processes, etc., can solve problems such as poor concrete consolidation quality and stratum collapse, so as to avoid accidents in wells, The effect of high degree of modularization and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

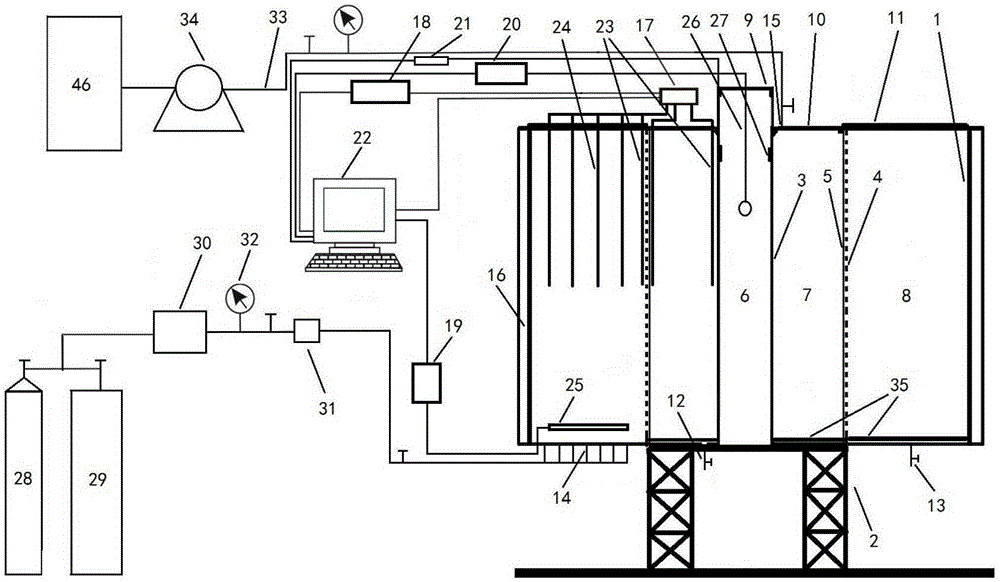

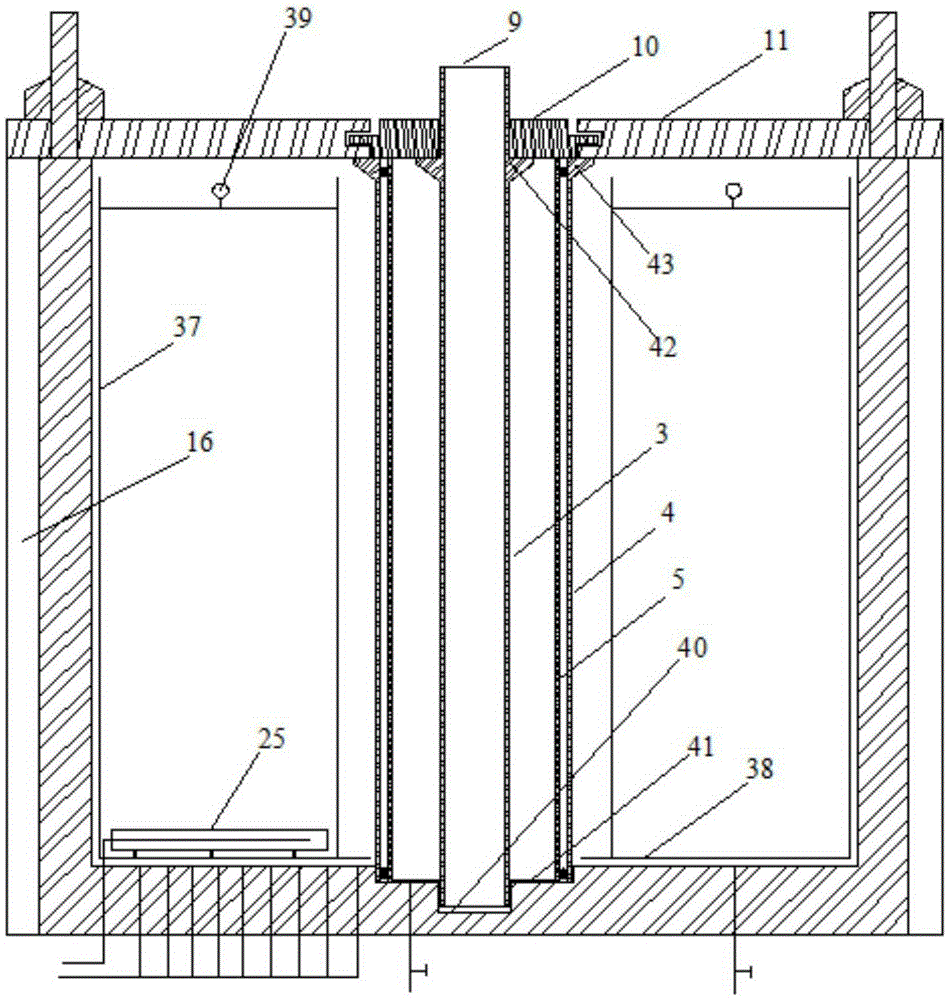

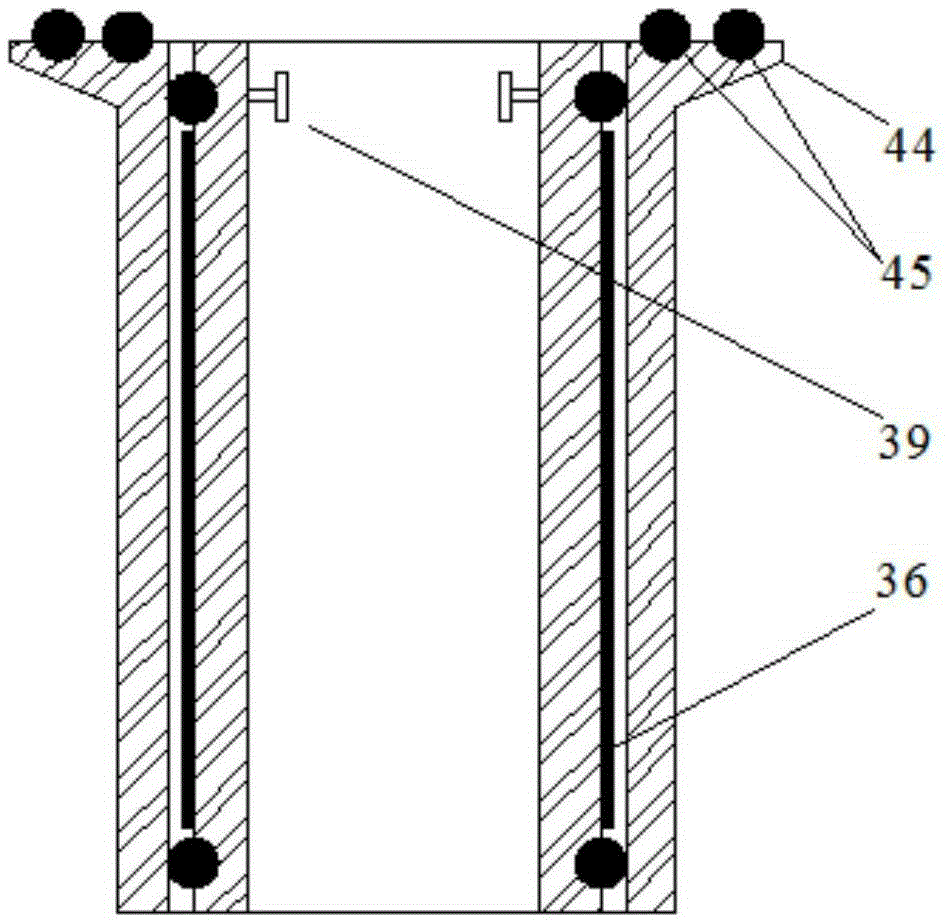

[0022] A low-temperature formation cementing simulation experiment reaction kettle containing hydrate / ice, including a kettle barrel 1, a kettle cover, a support 2, a data processing system, a gas / liquid pressurized injection system and a cement slurry injection system. The kettle barrel is installed in On the bracket, the outer wall of the kettle barrel is provided with an integrated temperature-control circulating bath sealing cover 16 to adjust the temperature in the kettle barrel. It is a coaxial acoustic wave detection chamber 6, a cement slurry chamber 7 and a simulated formation chamber 8, and the screen pipe is inserted into the second chamber wall 5; the bottom of the cement slurry chamber is provided with a first liquid discharge port 12, and the bottom of the simulated formation chamber is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com