A silicon-based thin epitaxial single-resurf level-shift structure

A level shifting and epitaxy technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve problems such as early breakdown of devices, large lateral diffusion of junction isolation, and long thermal process time, so as to reduce the impact of device withstand voltage , The effect of increasing the breakdown voltage and increasing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

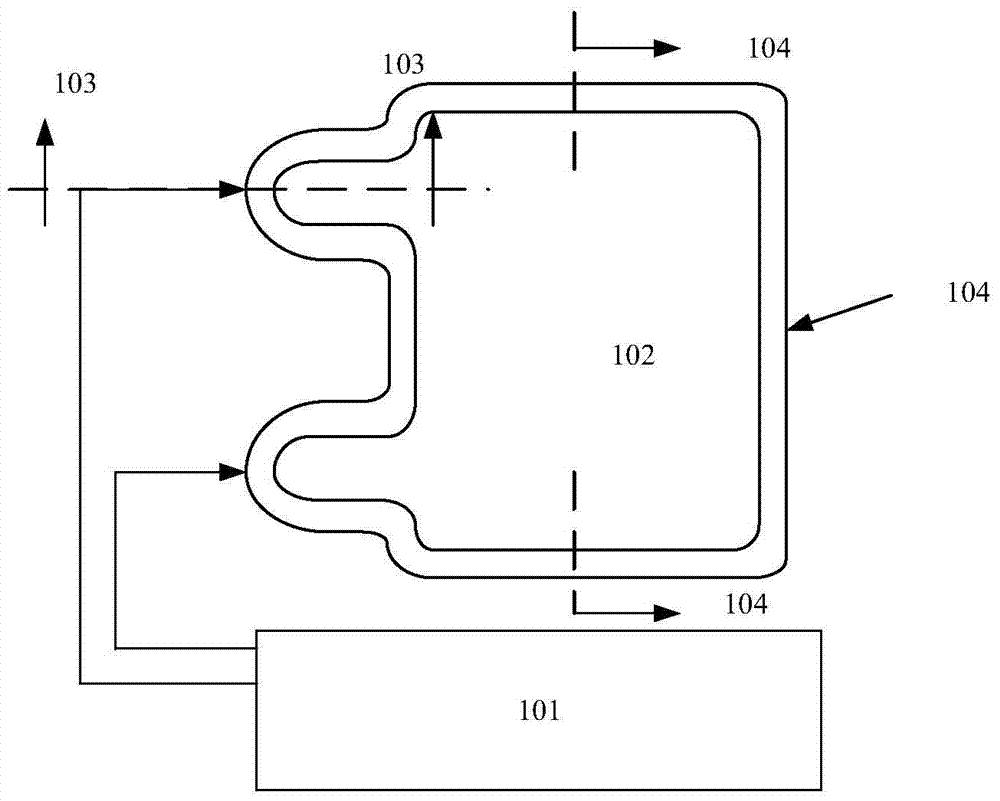

[0045] Figure 10 A schematic diagram of the silicon-based thin epitaxial single RESURF level shift structure provided by Embodiment 1 of the present invention. Including a pair of LDMOS 401, a high-end circuit 402 based on floating ground, a terminal 403, and two curved areas 404 and 405; for the first curved area 405, the curvature radius of the drain is increased to meet the withstand voltage requirement; for the second curved area In area 404, when side H remains unchanged, the radius of curvature of the arc on side B is reduced, and at the same time, the drift area in the straight track area gradually changes to the drift area in the curve area; and the radius of curvature of side B cannot be too low, and the basic withstand voltage requirements must be guaranteed.

Embodiment 2

[0047] Figure 11 It is a schematic diagram of the silicon-based thin epitaxial single RESURF level shift structure provided by Embodiment 2 of the present invention. Including a pair of LDMOS 401, a high-end circuit 402 based on floating ground, a terminal 403, and two curved areas 404 and 405; for the first curved area 405, the curvature radius of the drain is increased to meet the withstand voltage requirement; for the second curved area zone 404, increasing the radius of curvature of the B side and H side arcs at the same time, and the radius of curvature of the H side is much greater than that of the B side, so as to ensure that the length of the drift zone of the second curve zone is increased; at the same time, the drift zone of the straight track zone Fade to corner zone drift zone.

Embodiment 3

[0049] Figure 12 It is a schematic diagram of the silicon-based thin epitaxial single RESURF level shift structure provided by Embodiment 3 of the present invention. Including a pair of LDMOS 401, a high-end circuit 402 based on floating ground, a terminal 403, and two curved areas 404 and 405; for the first curved area 405, the curvature radius of the drain is increased to meet the withstand voltage requirement; for the second curved area In area 404, when increasing the radius of curvature of the arc on the H side, the radius of curvature of the arc on the B side is reduced to ensure that the length of the drift zone in the second curve area is increased; Press demand; at the same time, the drift zone in the straight track area gradually changes to the drift zone in the curve area.

[0050] The invention is also applicable to the thin epitaxial double RESURF structure, only needing to add ptop layer.

[0051] The invention is equally applicable in thick epitaxial structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com