Nested cutting machining device for boron carbide material workpiece

A processing device and boron carbide technology, applied in the field of mechanical processing, can solve the problems of low blank processing efficiency, crack and slag generation, etc., and achieve the effects of efficient processing to remove the blank, increase the clamping area, and facilitate disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to solve the problem of low processing efficiency of the blank allowance of boron carbide air bearing parts, the invention proposes a sleeve cutting processing device for workpieces made of boron carbide.

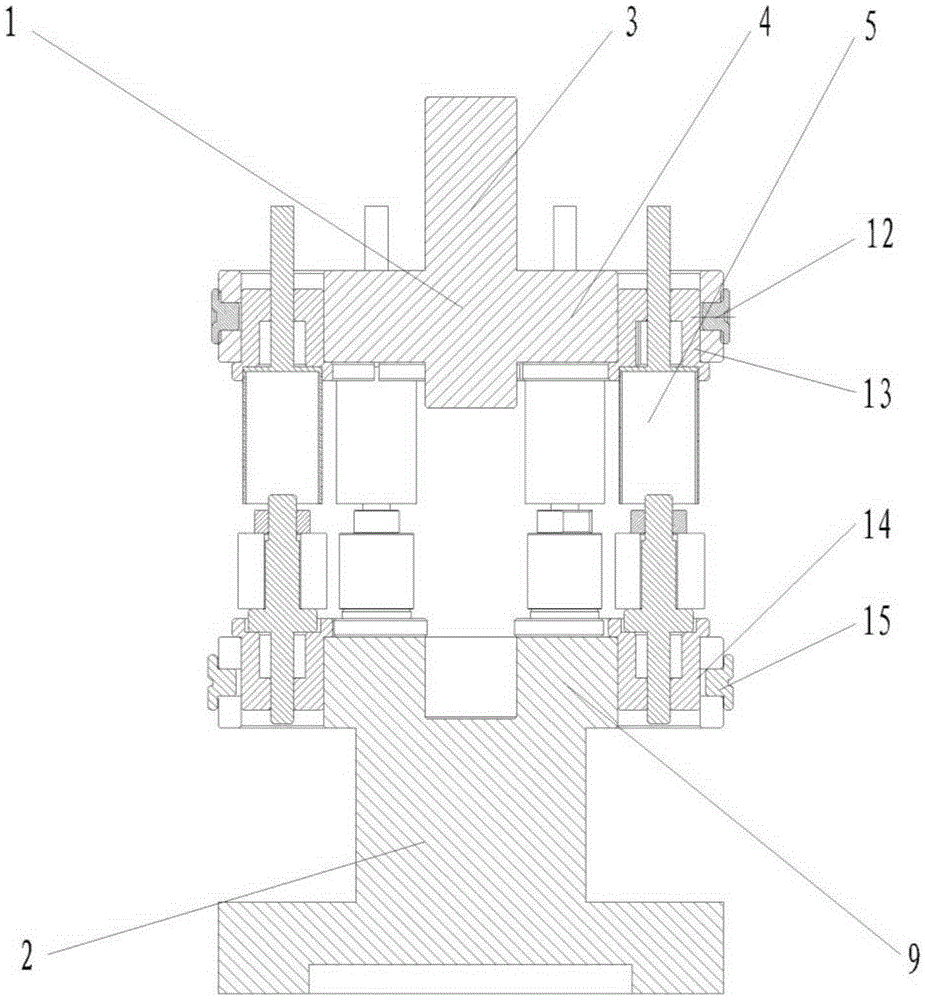

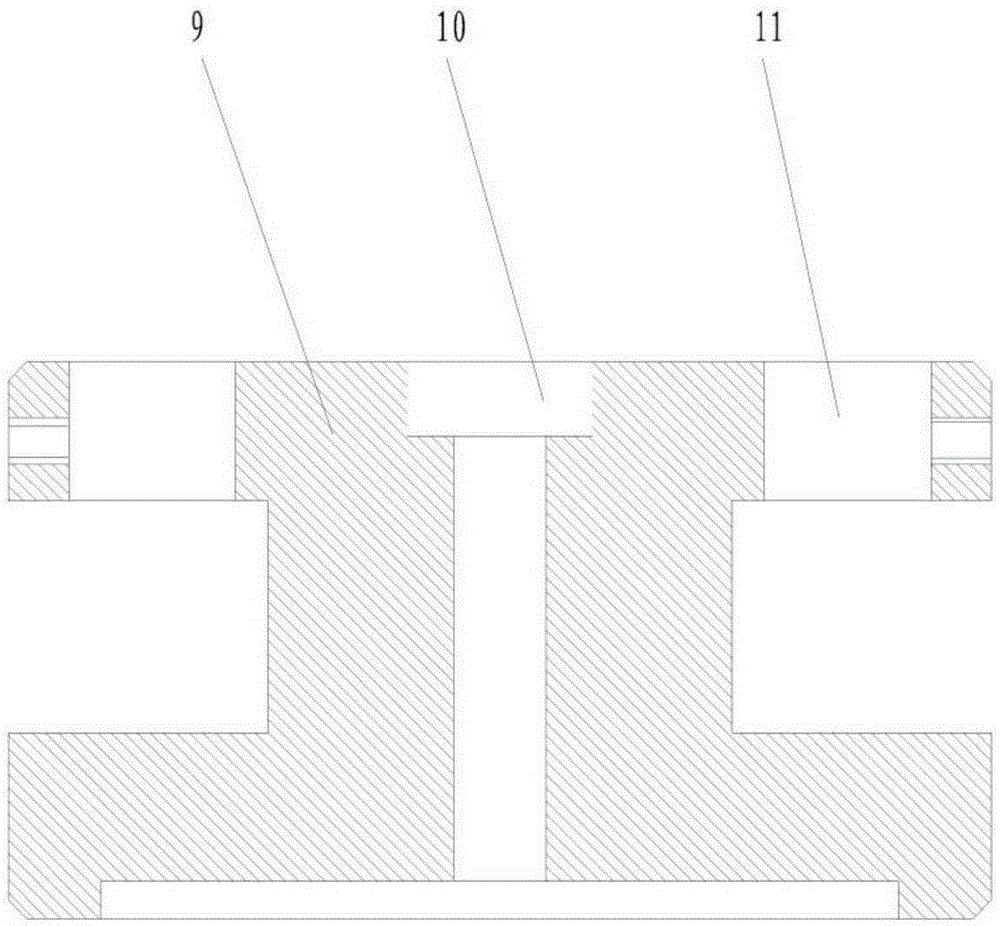

[0030] like figure 1 As shown, the device includes an EDM machine tool, an electrode mounting body 1 installed on the spindle of the EDM machine tool, and a workpiece mounting body 2 installed on the platform of the EDM machine tool;

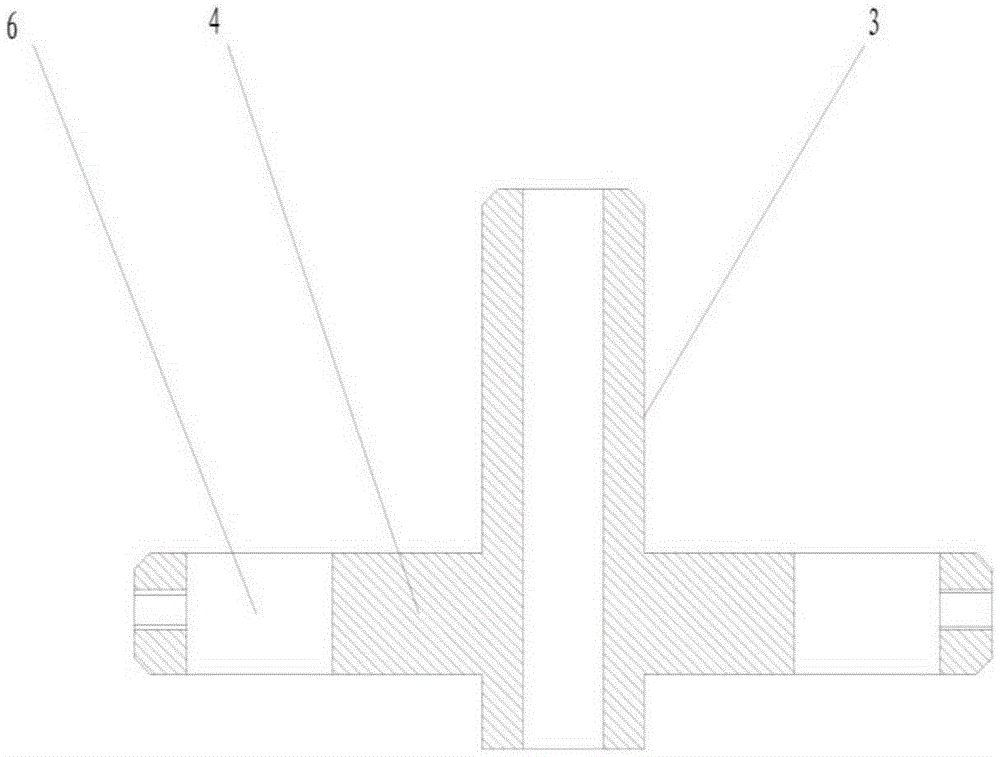

[0031] like figure 1 and figure 2 As shown, wherein, the electrode mounting body 1 includes a positioning shaft 3, a positioning disc 4 and an electrode head 5; one end of the positioning shaft 3 is connected to the main shaft of the EDM machine tool, and the other end passes through the center of the positioning disc 4 and extends for a section; the positioning disc 4 is provided with an electrode head installation hole 6; the electrode head 5 includes a handle 7 fixedly installed in the electrode head installation hole an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com