Novel method for comprehensively utilizing potassium feldspar

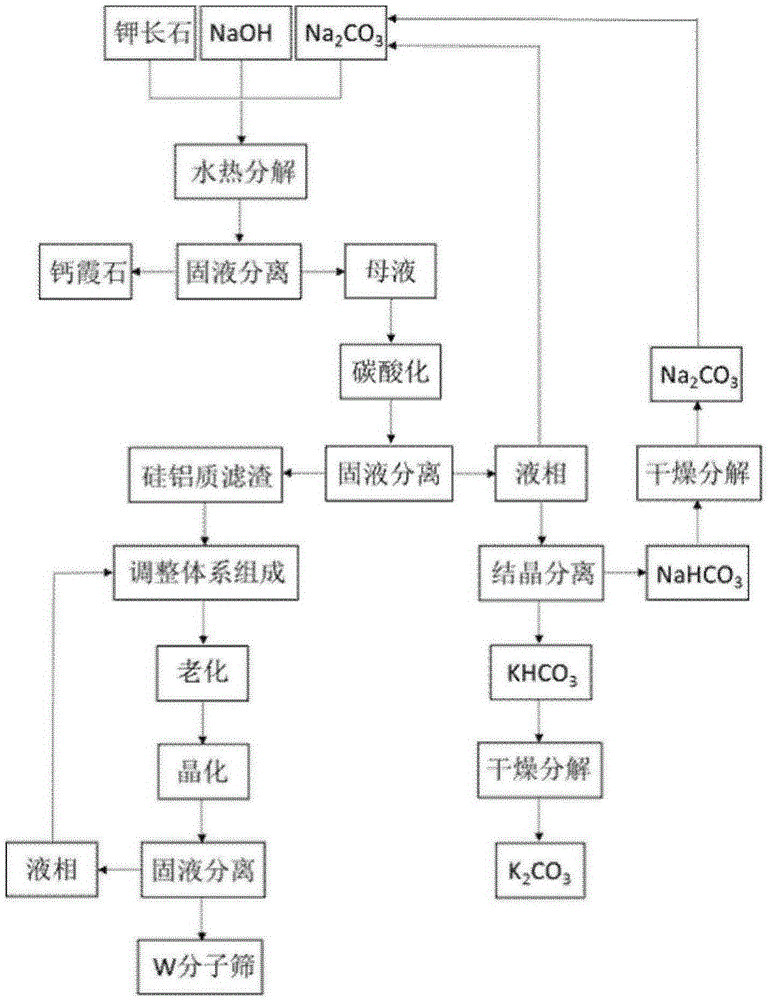

A technology of potassium feldspar and a new method, which is applied in the new field of comprehensive utilization of potassium feldspar, can solve the problems of waste of potassium resources and high energy consumption, and achieve the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

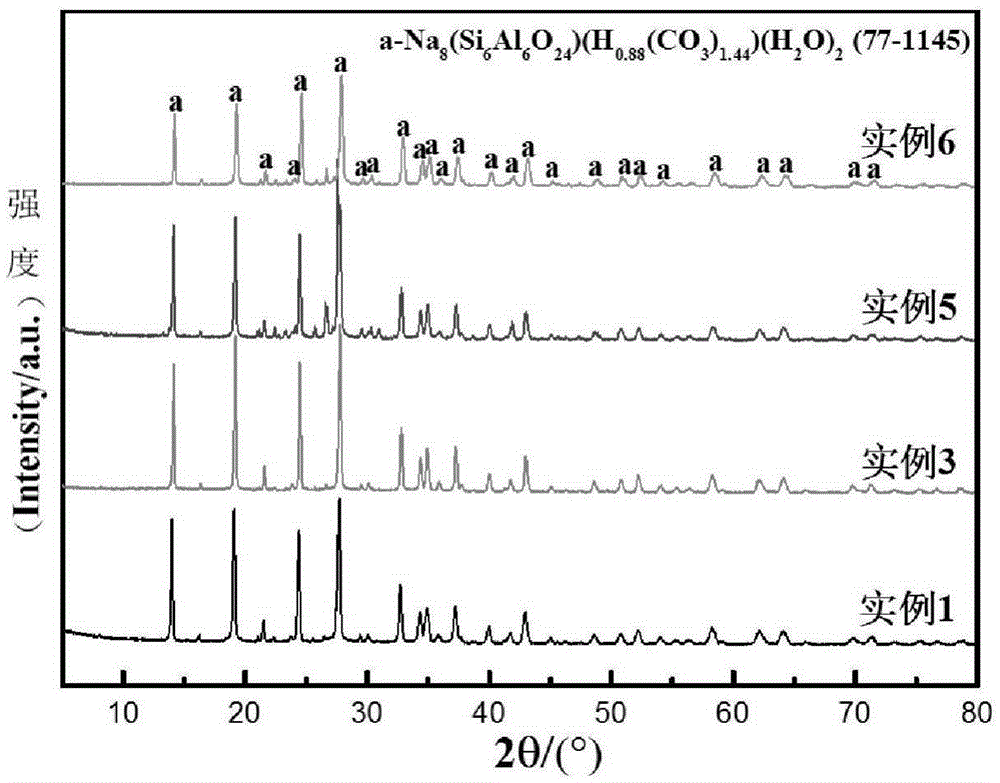

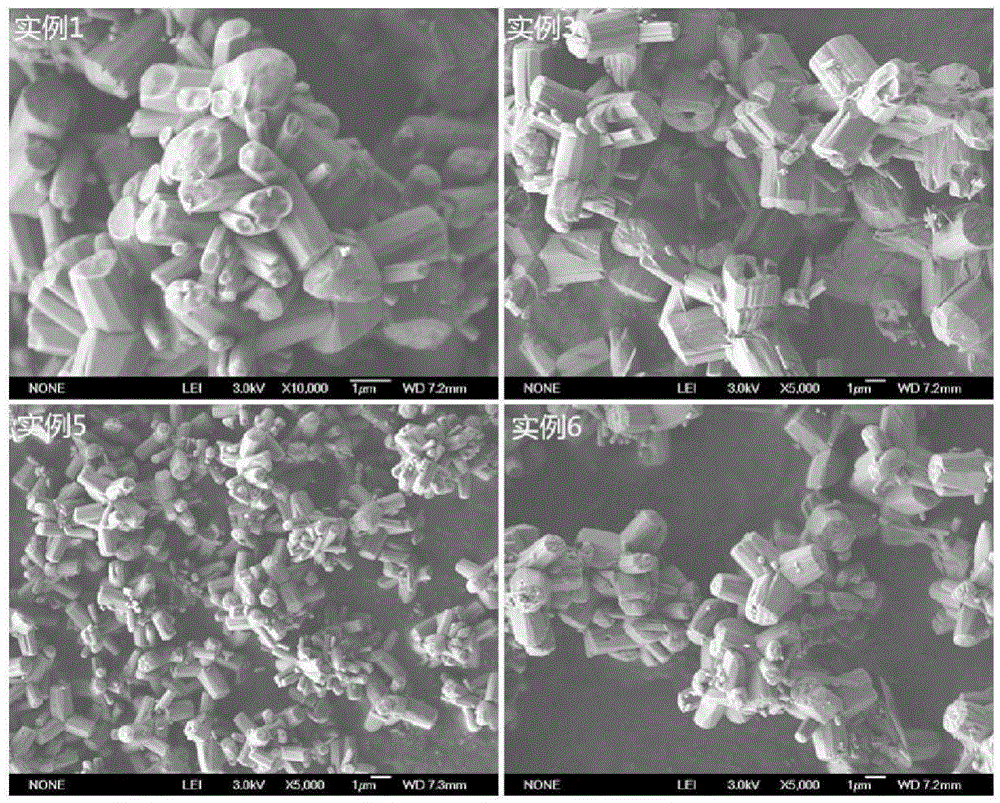

Examples

example 1

[0043] (1) Combine 7.50gNaOH and 7.50gNaOH 2 CO 3 with 15.00gH 2 O mix well and add to 100ml polytetrafluoroethylene liner, then add 10.00gK 2 Potassium feldspar powder with an O content of 8.61% passed through a 150-mesh sieve, stirred evenly, put it into an autoclave, and fixed it in a homogeneous stirring reactor (HZ-6), and the reactor was heated to 200°C, Start timing, stop heating after 4 hours of reaction, take out the lining after the reaction kettle is cooled, filter and wash the sample until the filter cake is free of CO 3 2- Afterwards, dry at 105°C for 2 hours. The obtained filtrate is a potassium-containing filtrate, that is, the potassium feldspar decomposition mother liquor, and the dissolution rate of potassium ions in the potassium feldspar is measured to be 95.33wt%.

[0044] (2) Pass CO into the potassium-containing filtrate in step (1) 2 Perform acidification to control SiO in the filtrate 3 2- The concentration is about 0.5mol / L, CO 2 The flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com