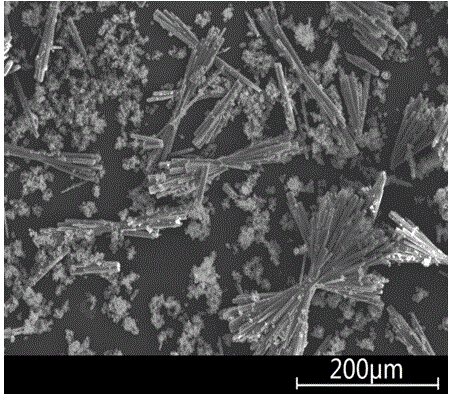

Preparation method of fascicular magnesium carbonate trihydrate crystals

A technology of magnesium carbonate trihydrate and crystals, applied in the direction of magnesium carbonate, etc., can solve the problems affecting the industrial production of magnesium salt fine chemical products, and achieve the effect of improving its own value, prolonging the product production chain, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

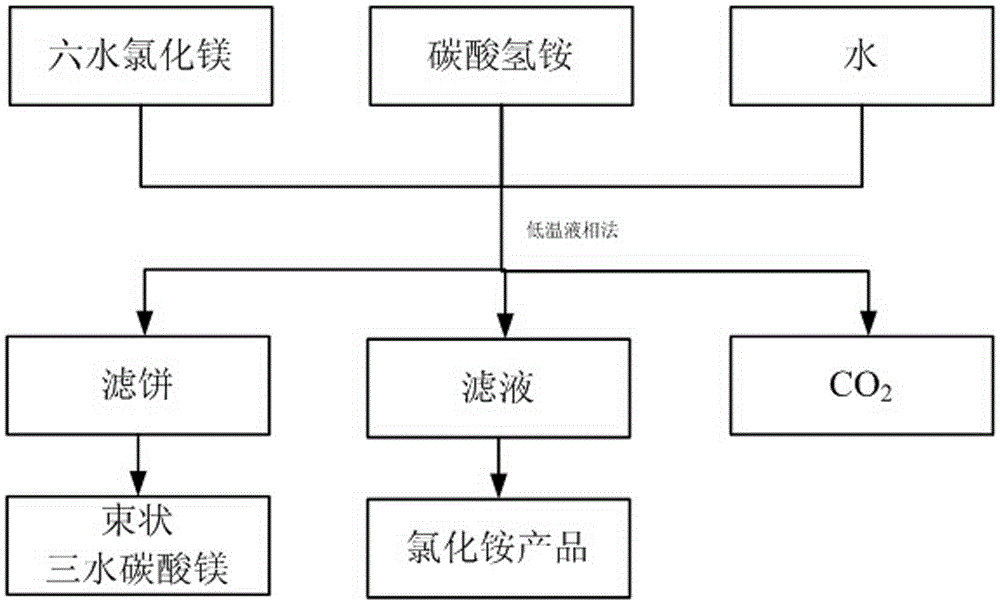

[0030] The preparation method of the beam-shaped magnesium carbonate trihydrate crystal of the present embodiment, as figure 1 shown, follow the steps below:

[0031] (1) Using water as a solvent, magnesium chloride hexahydrate was prepared into a 0.05mol / L solution, and ammonium bicarbonate was prepared into a 0.2mol / L solution;

[0032] (2) Add the magnesium chloride hexahydrate solution into the ammonium bicarbonate solution at room temperature, stir while adding, the stirring speed is 60r / min, after 10min, add the surfactant SDBS, the amount of surfactant SDBS Accounting for 0.01% of the magnesium chloride hexahydrate solution, the ammonium bicarbonate solution and the total mass, the addition is completed after 2 minutes, and then the pH is adjusted to 9.5 with ammonia water to obtain a reaction slurry;

[0033] (3) Move the slurry to a high-pressure reactor, the amount of slurry added accounts for 80% of the volume of the reactor, heat the slurry to 50°C and stir at th...

Embodiment 2

[0037]The preparation method of the beam-shaped magnesium carbonate trihydrate crystal of the present embodiment, as figure 1 shown, follow the steps below:

[0038] (1) Using water as a solvent, magnesium chloride hexahydrate was prepared into a 0.1mol / L solution, and ammonium bicarbonate was prepared into a 0.1mol / L solution;

[0039] (2) Add the magnesium chloride hexahydrate solution into the ammonium bicarbonate solution at room temperature, stir while adding, the stirring speed is 60r / min, after 8 minutes, add the surfactant SDBS, the amount of the surfactant SDBS Accounting for 0.5% of the magnesium chloride hexahydrate solution, ammonium bicarbonate solution and the total mass, the addition is completed after 2 minutes, and then the pH is adjusted to 9.3 with ammonia water to obtain a reaction slurry;

[0040] (3) Move the slurry to a high-pressure reactor, the amount of the slurry added accounts for 80% of the volume of the reactor, heat the slurry to 40°C and stir ...

Embodiment 3

[0044] The preparation method of the beam-shaped magnesium carbonate trihydrate crystal of the present embodiment, as figure 1 shown, follow the steps below:

[0045] (1) Using water as a solvent, magnesium chloride hexahydrate was prepared into a 0.2mol / L solution, and ammonium bicarbonate was prepared into a 0.05mol / L solution;

[0046] (2) Add the magnesium chloride hexahydrate solution into the ammonium bicarbonate solution at room temperature, stir while adding, the stirring speed is 60r / min, after 5min, add the surfactant SDBS, the amount of surfactant SDBS Accounting for 1% of the magnesium chloride hexahydrate solution, the ammonium bicarbonate solution and the total mass, the addition is completed after 2 minutes, and then the pH is adjusted to 9.0 with ammonia water to obtain a reaction slurry;

[0047] (3) Move the slurry to a high-pressure reactor, the amount of slurry added accounts for 80% of the volume of the reactor, heat the slurry to 40°C and stir at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com