Sewage enhanced treatment system and method

A technology for enhanced treatment and sewage, applied in the direction of water/sewage multi-stage treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve the restrictions on process promotion and application, odor and heavy metals are not well removed , secondary settling tank load increase and other issues, to avoid chemical residues and secondary pollution, improve the effect of secondary treatment, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

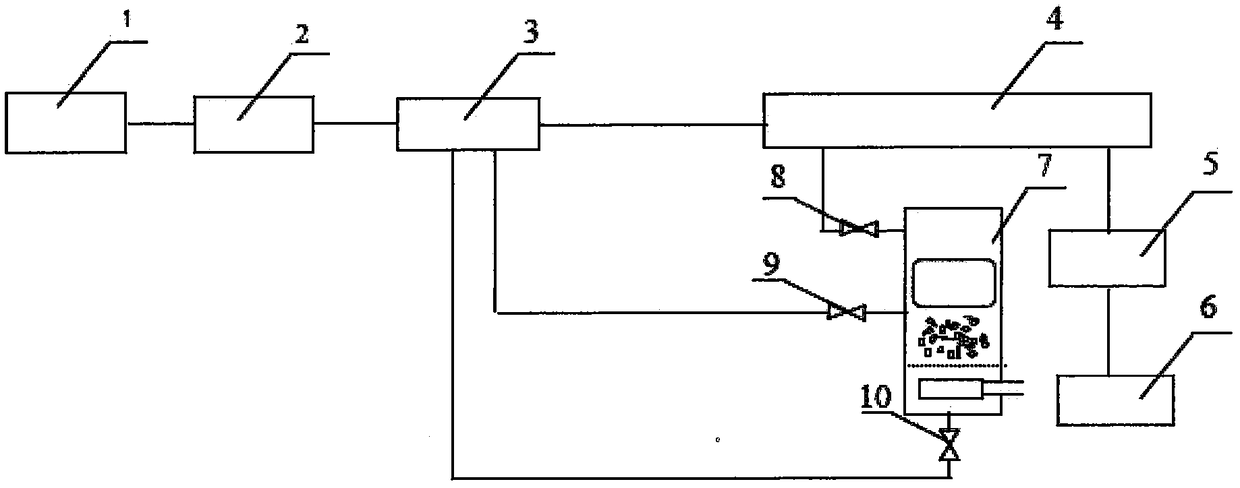

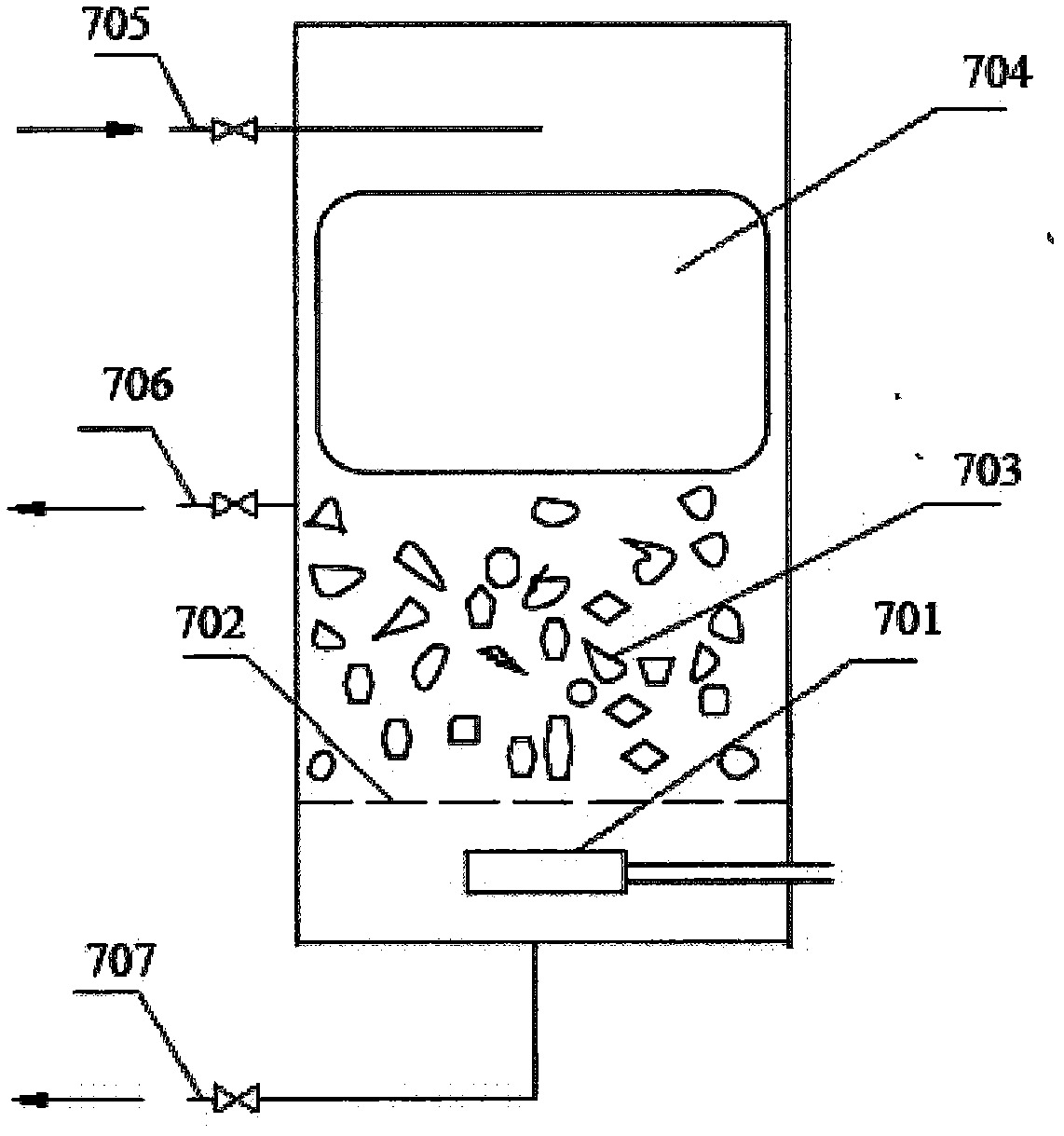

[0027] Such as figure 1As shown, the enhanced sewage treatment system includes sequentially connected grille 1, advection primary settling tank 2, push flow biochemical aeration tank 3, radial flow secondary settling tank 4, centrifugal sludge thickening device 5, stacking screw Type sludge dewatering device 6, also includes sludge cultivation tank 7, described sludge cultivation tank 7, such as figure 2 As shown, it includes a blast aeration device 701, a perforated plate 702, a pumice filler layer 703, a humus soil filler layer 704, a mud inlet pipe 705, a mud discharge pipe 706, and a mud discharge pipe 707. The blast aeration device 701 Located at the bottom of the sludge cultivation tank 7; the perforated plate 702 is located above the blast aeration device 701, the pumice filler layer 703 is located on the perforated plate 702, and the humus soil filler layer 704 is located on the On the pumice filler layer 703, one end of the mud inlet pipe 705 is located above the hu...

Embodiment 2

[0036] Such as figure 1 As shown, the enhanced sewage treatment system includes sequentially connected grille 1, vertical flow primary sedimentation tank 2, complete mixed biochemical aeration tank 3, radial flow secondary sedimentation tank 4, stacked screw sludge thickening device 5, The belt sludge dewatering device 6 also includes a sludge cultivation tank 7, and the sludge cultivation tank 7, such as figure 2 As shown, it includes a surface aeration device 701, a perforated plate 702, a pumice filler layer 703, a humus soil filler layer 704, a mud inlet pipe 705, a mud discharge pipe 706, and a mud discharge pipe 707. The surface aeration device 701 is located at the The bottom of the sludge cultivation tank 7; the perforated plate 702 is located above the surface aeration device 701, the pumice filler layer 703 is located on the perforated plate 702, and the humus soil filler layer 704 is located on the pumice filler On the layer 703, one end of the mud inlet pipe 705 ...

Embodiment 3

[0045] Such as figure 1 As shown, the enhanced sewage treatment system includes grid 1, radial flow primary settling tank 2, combined biochemical aeration tank 3, vertical flow secondary settling tank 4, central drive sludge thickening device 5, plate and frame connected in sequence Type dehydration device 6, also includes sludge cultivation tank 7, described sludge cultivation tank, such as figure 2 As shown, it includes a microporous aeration device 701, a perforated plate 702, a pumice filler layer 703, a humus soil filler layer 704, a mud inlet pipe 705, a mud discharge pipe 706, and a mud discharge pipe 707. The microporous aeration device 701 Located at the bottom of the sludge cultivation tank 7; the perforated plate 702 is located above the microporous aeration device 701, the pumice filler layer 703 is located on the perforated plate 702, and the humus soil filler layer 704 is located on the On the pumice filler layer 703, one end of the mud inlet pipe 705 is locate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com