Anti-crack binding agent for building partition wall battens

A technology of partition wall slats and adhesives, applied in the field of building materials, can solve problems such as bond strength, flexibility, mismatch of shrinkage values, etc., to improve construction convenience, improve crack resistance, and strong permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

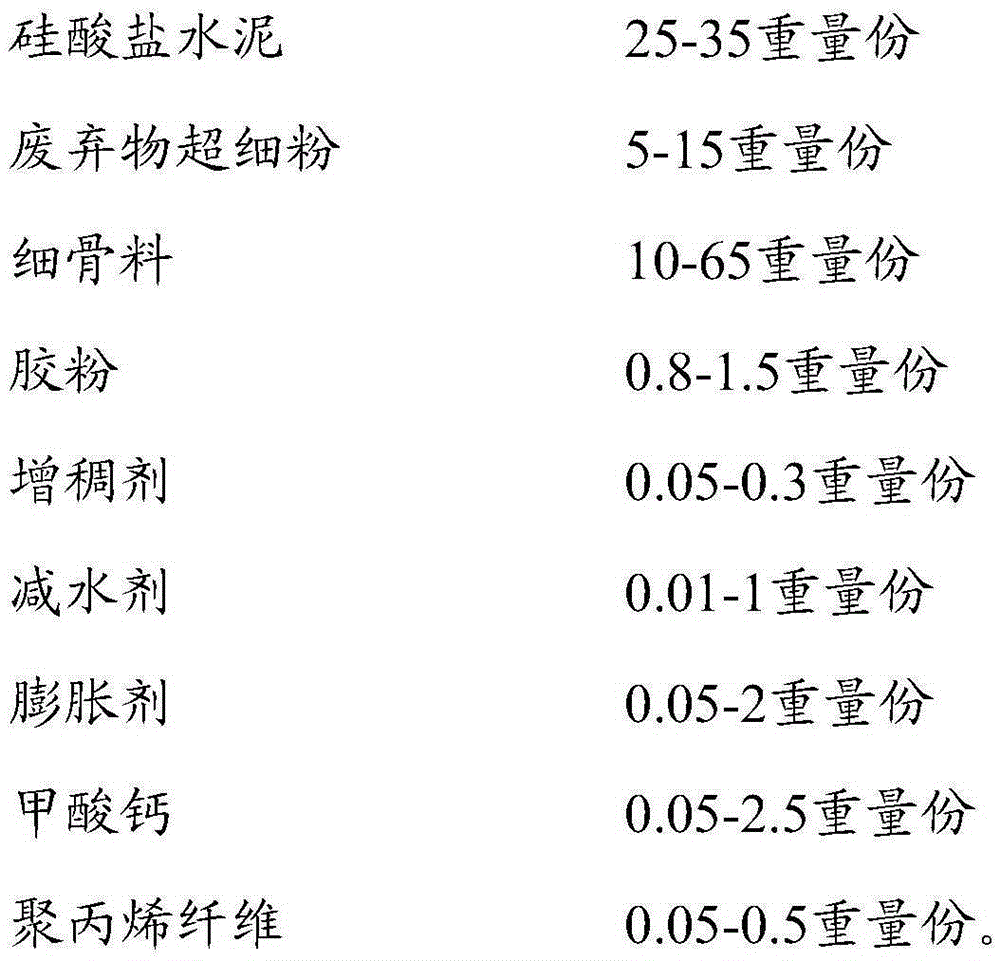

[0029] An anti-crack adhesive for building partition wall slats, consisting of the following components:

[0030]

[0031] Wherein, the specific surface area of the superfine powder of construction waste is 565m 2 / kg; the fiber length of the polypropylene fiber is 3mm.

[0032] The anti-crack adhesive for building partition wall strips provided in this embodiment is especially suitable for filling and bonding the cracks of concrete hollow partition wall strips.

Embodiment 2

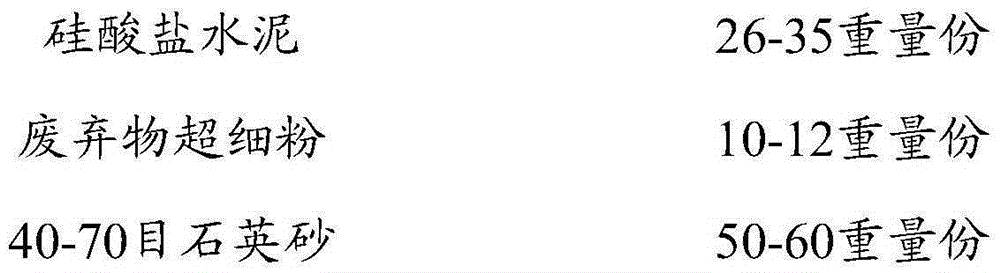

[0034] An anti-crack adhesive for building partition wall slats, consisting of the following components:

[0035]

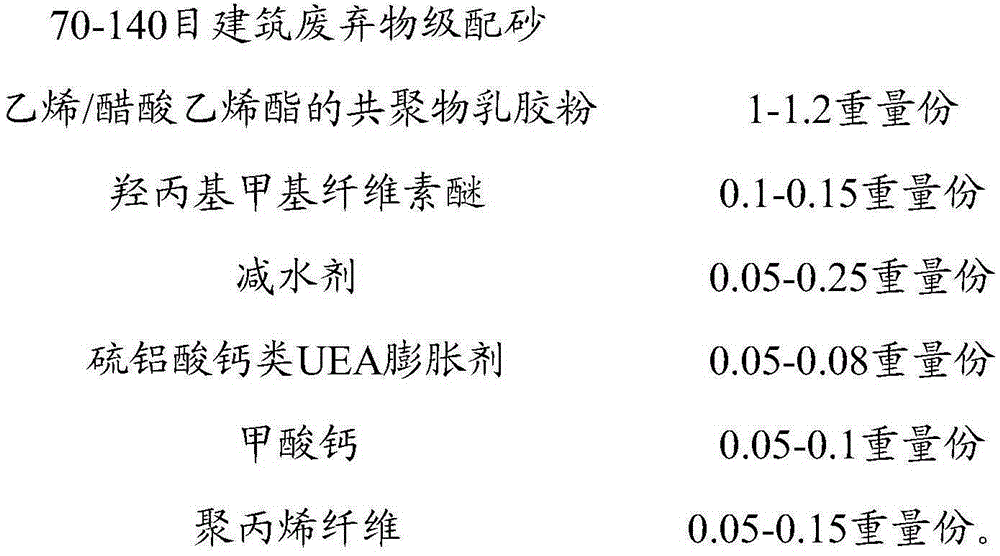

[0036]

[0037] Wherein, the specific surface area of the superfine powder of construction waste is 565m 2 / kg; the fiber length of the polypropylene fiber is 3mm.

[0038] The anti-crack adhesive for building partition wall strips provided in this embodiment is especially suitable for filling and bonding the cracks of lightweight concrete foam partition wall strips.

Embodiment 3

[0040] An anti-crack adhesive for building partition wall slats, consisting of the following components:

[0041]

[0042] Wherein, the ceramic polishing powder waste superfine powder specific surface area is 621m 2 / kg; the fiber length of the polypropylene fiber is 3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com