Preparation method of antibacterial ceramic

A technology of antibacterial ceramics and water glass solution, which is applied in the field of new ceramic materials, can solve the problems of easy oxidation and discoloration of antibacterial metal ions, harsh environment for antibacterial action, and low utilization rate of antibacterial agents, so as to protect product quality or human health, ceramics as a whole Excellent texture and strong anti-destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

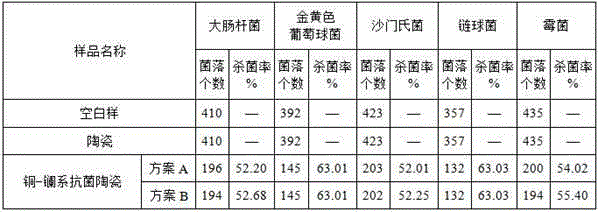

Examples

Embodiment 1

[0027] Embodiment 1: the preparation method of this silver-based antibacterial ceramic is as follows:

[0028] (1) Assemble the constant temperature stirring reaction device, preheat the hot water glass solution and the baking soda solution to 90°C respectively, measure the two reactants with a volume ratio of 1:1.3 and place them in the reaction vessel at 90°C at 500rpm Stir and mix for 15min, wherein the water glass solution concentration is 10wt%, and the sodium bicarbonate solution concentration is 5wt%;

[0029](2) Take the water glass solution and the baking soda solution with a volume ratio of 1:1.3 and preheat them to 90°C, and then pour the preheated water glass solution and baking soda solution into the water at a stirring rate of 150rpm. In the reaction solution of step (1), place the mixture at 90°C for 20 minutes, adjust the pH to 2 with nitric acid, and finally add 0.001 mol / L silver nitrate solution to react for 1 hour to obtain a gel-like reactant. The cooled ...

Embodiment 2

[0041] Embodiment 2: the preparation method of this silver-based antibacterial ceramic is as follows:

[0042] (1) Preheat the hot water glass solution and the baking soda solution to 85°C respectively, measure the two reactants with a volume ratio of 1:1.5, place them in a reaction vessel at 85°C and stir and mix at 400rpm for 25min, the water glass solution Concentration is 5wt%, and baking soda solution concentration is 15wt%;

[0043] (2) Take the water glass solution and the baking soda solution with a volume ratio of 1:1.5 and preheat them to 90°C, and then pour the preheated water glass solution and baking soda solution into the water at a stirring rate of 200rpm. In the reaction solution of step (1), place the mixture at 85°C for 25 minutes, adjust the pH to 2 with nitric acid, and finally add 0.005 mol / L silver nitrate solution to react for 1.5 hours to obtain a gel-like reactant. After cooling, The gel-like reactant was vacuum filtered, and then the filtered product...

Embodiment 3

[0052] Embodiment 3: the preparation method of this zinc series antibacterial ceramics is as follows:

[0053] (1) Preheat the hot water glass solution and the baking soda solution to 85°C respectively, measure the two reactants with a volume ratio of 1:1.25, place them in a reaction vessel at 85°C and stir and mix at 450rpm for 15min, in which the water glass Solution concentration is 20wt%, and baking soda solution concentration is 5wt%;

[0054] (2) Take the water glass solution and the baking soda solution with a volume ratio of 1:1.25 and preheat them to 85°C respectively, and then pour the preheated water glass solution and baking soda solution into the In the reaction solution of step (1), place the mixture at 85°C for 25 minutes, adjust the pH to 6 with nitric acid, and finally add 0.6 mol / L zinc sulfate solution to react for 2 hours to obtain a gel-like reactant. The cooled The gel-like reactant is vacuum filtered, and then the filtered product is baked at 115°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com