Preparation and Application of a Ratio-type Fluorescent Oxygen Sensing Membrane

An oxygen sensing film, ratio-type technology, applied in the field of sensing, can solve the problems of reducing stability, sensitivity and accuracy, and achieve the effects of high sensitivity and accuracy, large detection range and long excitation life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

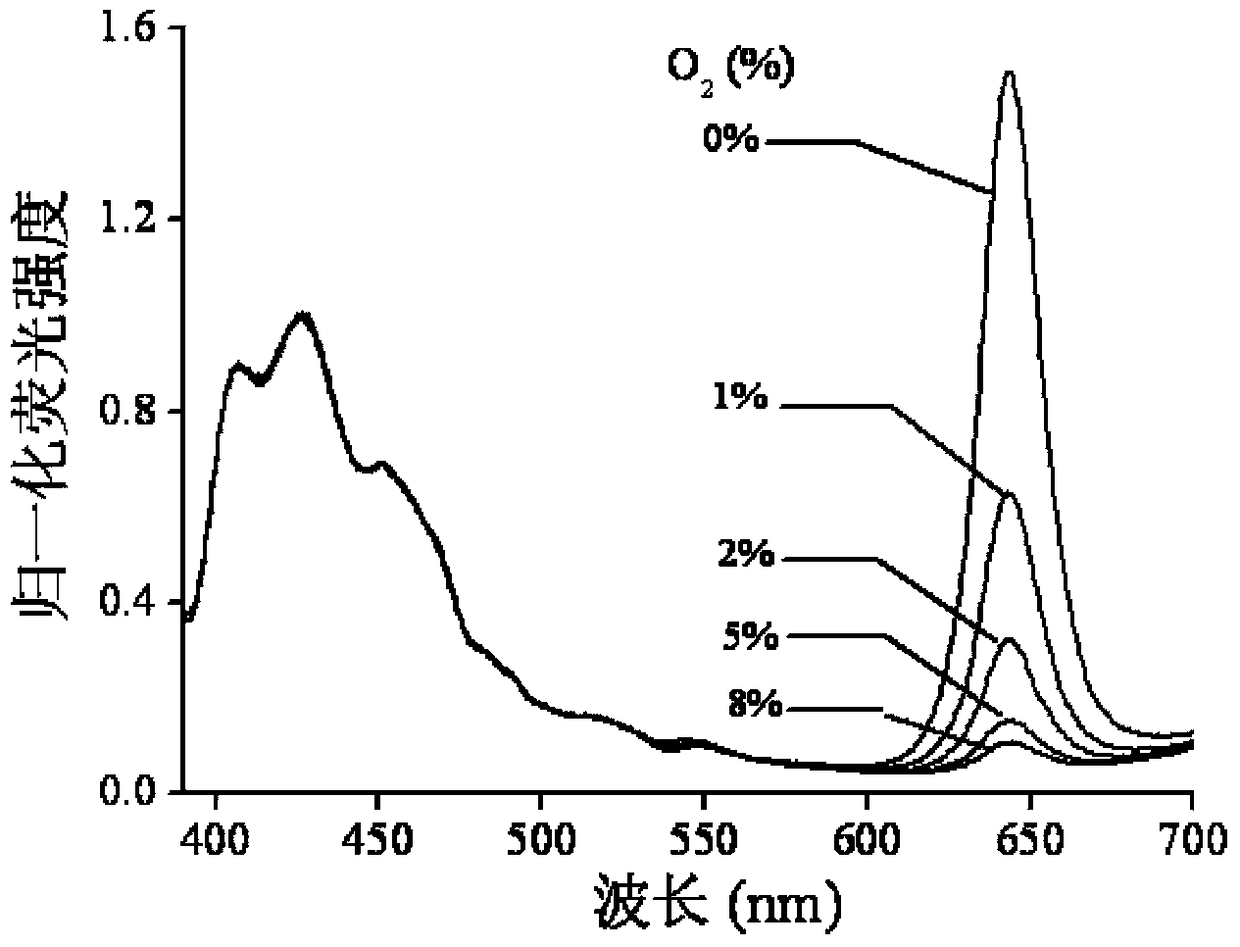

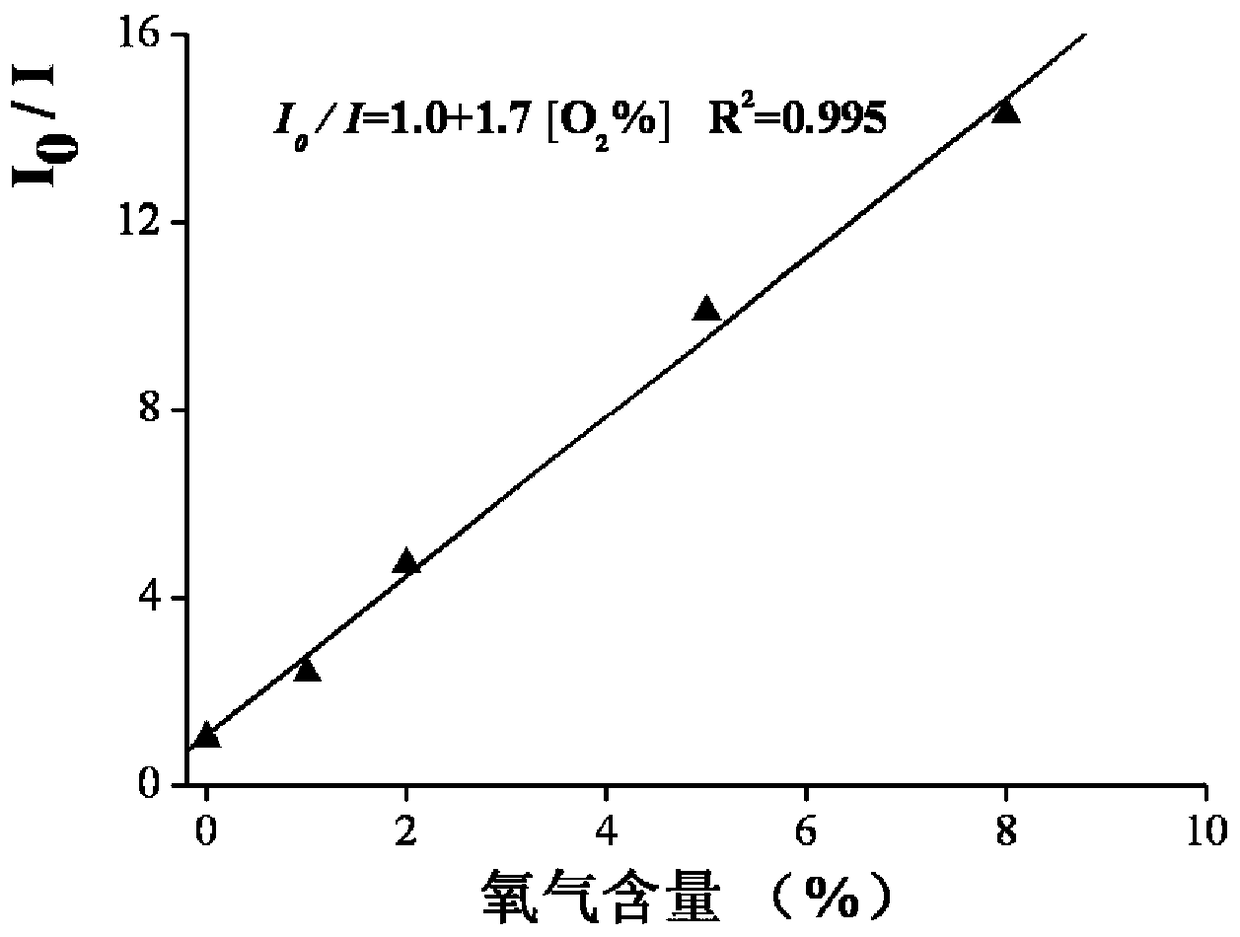

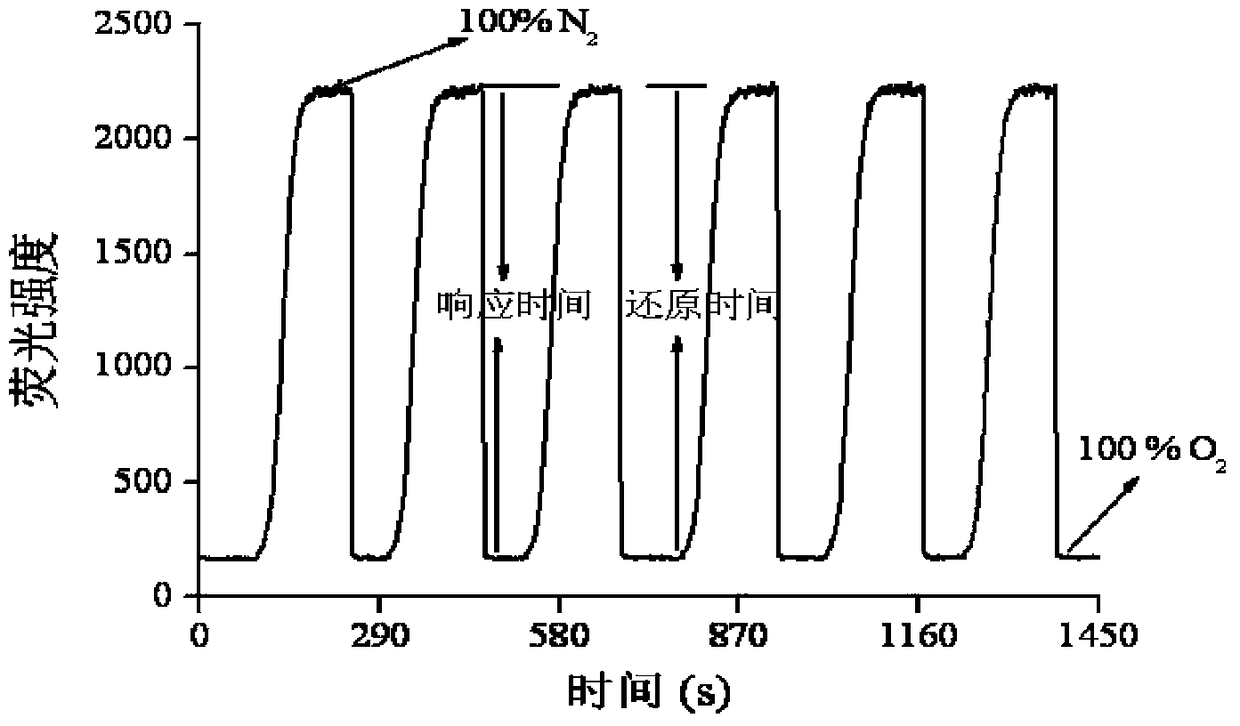

[0032] Prepare 4 mg / mL meso-(pentafluorophenyl)porphyrin platinum complex (PtFTPP) in tetrahydrofuran (THF) and 4,4'-bis(2-benzoxazolyl)stilbene (BBS) Tetrahydrofuran (THF) saturated solution, the two are mixed in a volume ratio of 30:1 to prepare a fluorescent indicator solution;

[0033] Under ultrasonic conditions, mix tetramethoxysilane, dimethyldimethoxysilane and 0.01mol / L HCl at a volume ratio of 1:1.5:1.5, place the mixture in a water bath at 60°C and stir for 2 hours at constant temperature, and remove the lower layer Mix the oily solution and the fluorescent indicator solution at a ratio of 4:1, stir for 5 minutes to obtain a fluorescent gel solution, take the fluorescent gel solution to form a film on the treated glass slide by spin coating or drop coating, and dry it in an oven at 80°C for 20 hours Oxygen sensing membrane was prepared.

Embodiment 2

[0035] Prepare 2 mg / mL meso-(pentafluorophenyl)porphyrin platinum complex (PtFTPP) in tetrahydrofuran (THF) and 4,4'-bis(2-benzoxazolyl)stilbene (BBS) Tetrahydrofuran (THF) saturated solution, the two are mixed in a volume ratio of 10:1 to prepare a fluorescent indicator solution;

[0036] Under ultrasonic conditions, mix tetramethoxysilane, dimethyldimethoxysilane and 0.01mol / L HCl in a volume ratio of 1:1.8:1.5, place the mixed solution in a water bath at 50°C and stir for 3 hours, and take the lower layer of oil Fluorescent solution and fluorescent indicator solution were mixed at a ratio of 2:1, stirred for 10 minutes to obtain a fluorescent gel solution, and the fluorescent gel solution was taken to form a film on the treated glass slide by spin coating, dip coating, drop coating or pull-up method, and then dried in an oven. The oxygen sensing membrane was prepared by drying at 60°C for 30 h.

Embodiment 3

[0038] Prepare 8 mg / mL meso-(pentafluorophenyl)porphyrin platinum complex (PtFTPP) in tetrahydrofuran (THF) and 4,4'-bis(2-benzoxazolyl)stilbene (BBS) Tetrahydrofuran (THF) saturated solution, the two are mixed in a volume ratio of 60:1 to prepare a fluorescent indicator solution;

[0039] Under ultrasonic conditions, mix tetramethoxysilane, dimethyldimethoxysilane and 0.01mol / L HCl in a volume ratio of 1:2:1.5, place the mixture in a water bath at 80°C and stir for 1 hour, and take the lower layer of oil Fluorescent solution and fluorescent indicator solution were mixed at a ratio of 6:1, stirred for 15 minutes to obtain a fluorescent gel solution, and the fluorescent gel solution was taken to form a film on the treated glass slide by spin coating or drop coating, and dried in an oven at 90°C for 15 hours. Oxygen sensing membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com