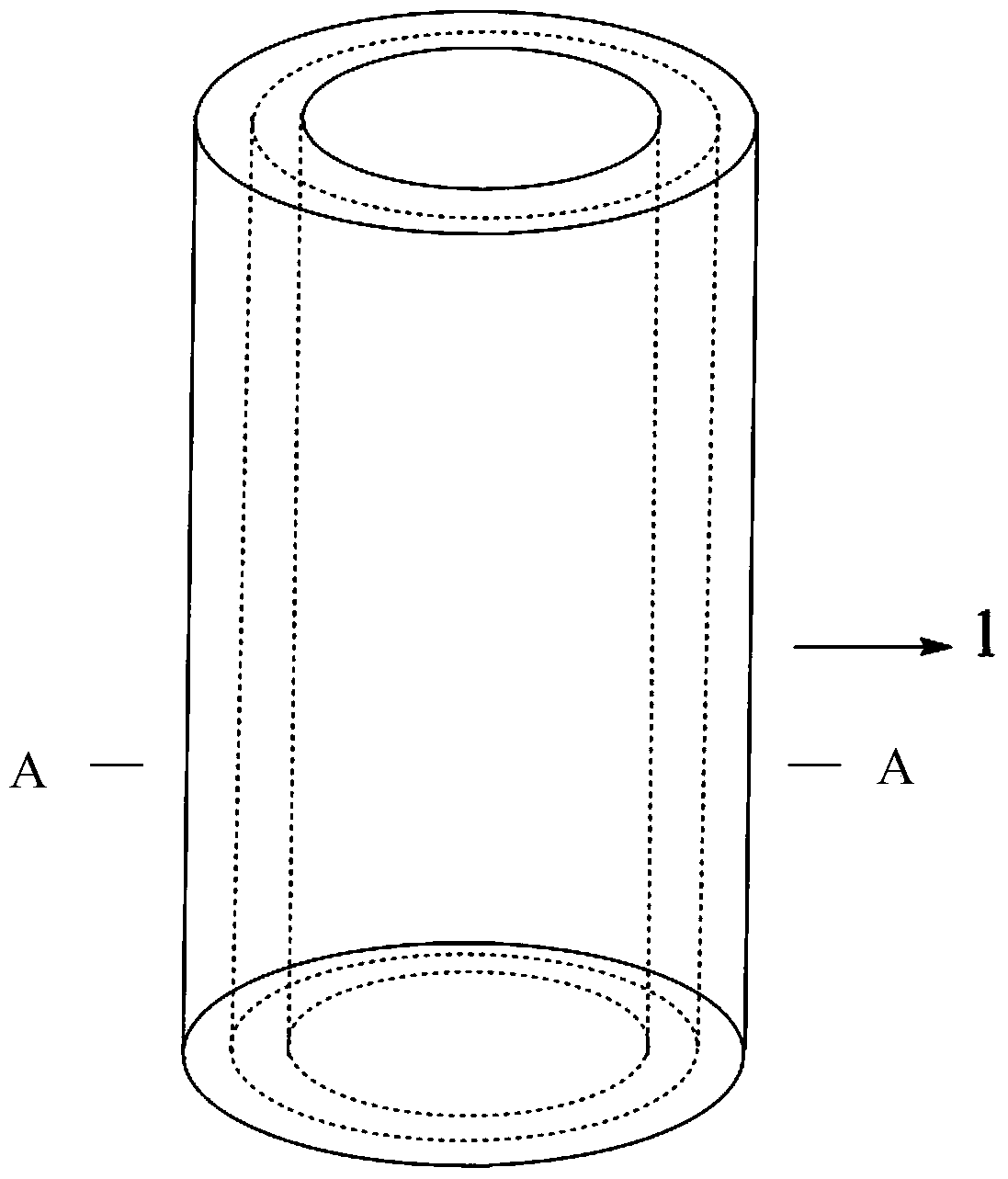

A hollow tubular biodegradable drug delivery system and its preparation method

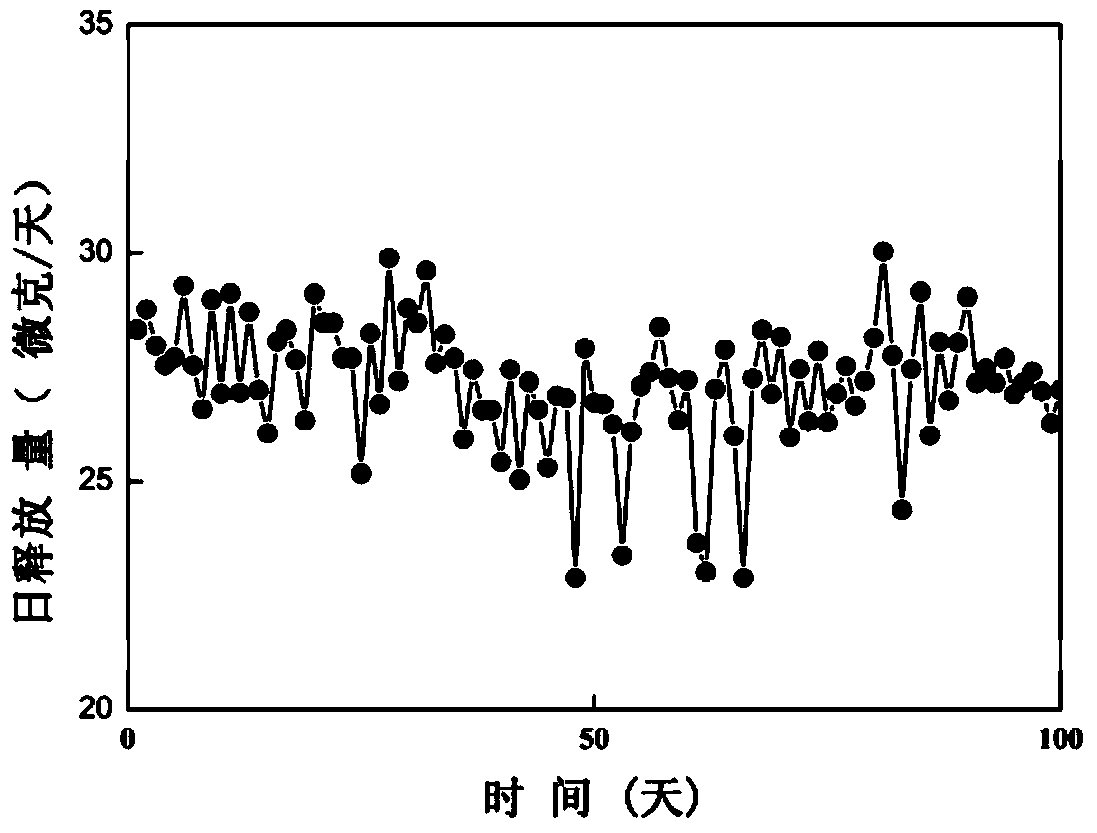

A biodegradable drug delivery system technology, applied in the field of hollow tubular biodegradable drug delivery system and its preparation, can solve the problems of "explosive release of drugs, difficulty in achieving constant drug release, etc., and achieve a wide range of clinical applications" Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Poly(2,2-dimethyl-trimethylene carbonate) was prepared by ring-opening polymerization of 2,2-dimethyl-trimethylene carbonate, a derivative of trimethylene carbonate. Mix poly(2,2-dimethyl-trimethylene carbonate) and gestodene in a mass ratio of 3:1, and add 2-methyl-4-(2 - Methylpropyl) phenylacetic acid, after mixing evenly, extruding with a miniature single-screw extruder to obtain a hollow tubular biodegradable drug delivery system with an outer diameter of 1.0-5.0 mm and a wall thickness of 0.2-2 mm.

Embodiment 2

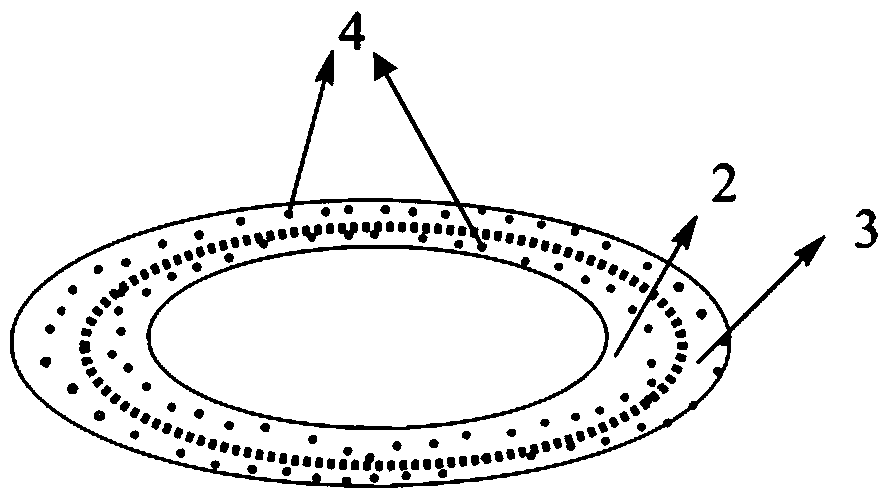

[0039] Mix polycaprolactone and gestodene at a mass ratio of 2.5:1, add acetaminophen accounting for 5% of the total mass of the mixture, and mix evenly. The hollow tubular drug delivery system prepared in Example 1 is used as a mold core and placed in the middle of the mixed materials, and put together into a mold for compression molding to obtain a double-layer hollow tubular drug delivery system. Among them, the hollow tubular drug delivery system prepared in Example 1 is used as the inner layer, the outer layer of the hollow tubular biodegradable drug delivery system (outer diameter 1.4-9.0 mm, wall thickness 0.2-2 mm) formed by molding and the hollow tubular biodegradable drug delivery system The inner layer of the biodegradable drug delivery system (with an outer diameter of 1.0-5.0 mm and a wall thickness of 0.2-2 mm) is firmly combined to form a double-layer hollow tubular biodegradable drug delivery system.

Embodiment 3

[0041] Mix poly(trimethylene carbonate-hydroxycaprolactone) and paclitaxel uniformly at a mass ratio of 4:1, and then inject with an injection molding machine to obtain a hollow tubular drug delivery system with an outer diameter of 0.2-3.0 mm and a wall thickness of 0.05-1.0 mm the inner layer. Mix poly(p-dioxanone-lactide) and paclitaxel at a mass ratio of 5:1, add 2-(acetoxy)benzoic acid accounting for 3% of the total mass of the mixture, and mix well. Place the inner layer of the obtained hollow tubular drug delivery system as a mold core in the middle of the mixed materials, put them together into the mold for compression molding, and form the outer layer of the hollow tubular biodegradable drug delivery system (outer diameter: 0.3 to 5.0 mm) by molding. , wall thickness 0.05-1.0mm) and the inner layer of the hollow tubular biodegradable drug delivery system (outer diameter 0.2-3.0mm, wall thickness 0.05-1.0mm) are firmly combined to form a double-layer hollow tubular bio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com