Low-resistance forced water cooling drip pipe type demister and demisting method

A water-cooled drop type, mist eliminator technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of insufficient flushing, low dust removal efficiency, large flue gas flow resistance, etc., and is not easy to block and scale. , The effect of uniform flow and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

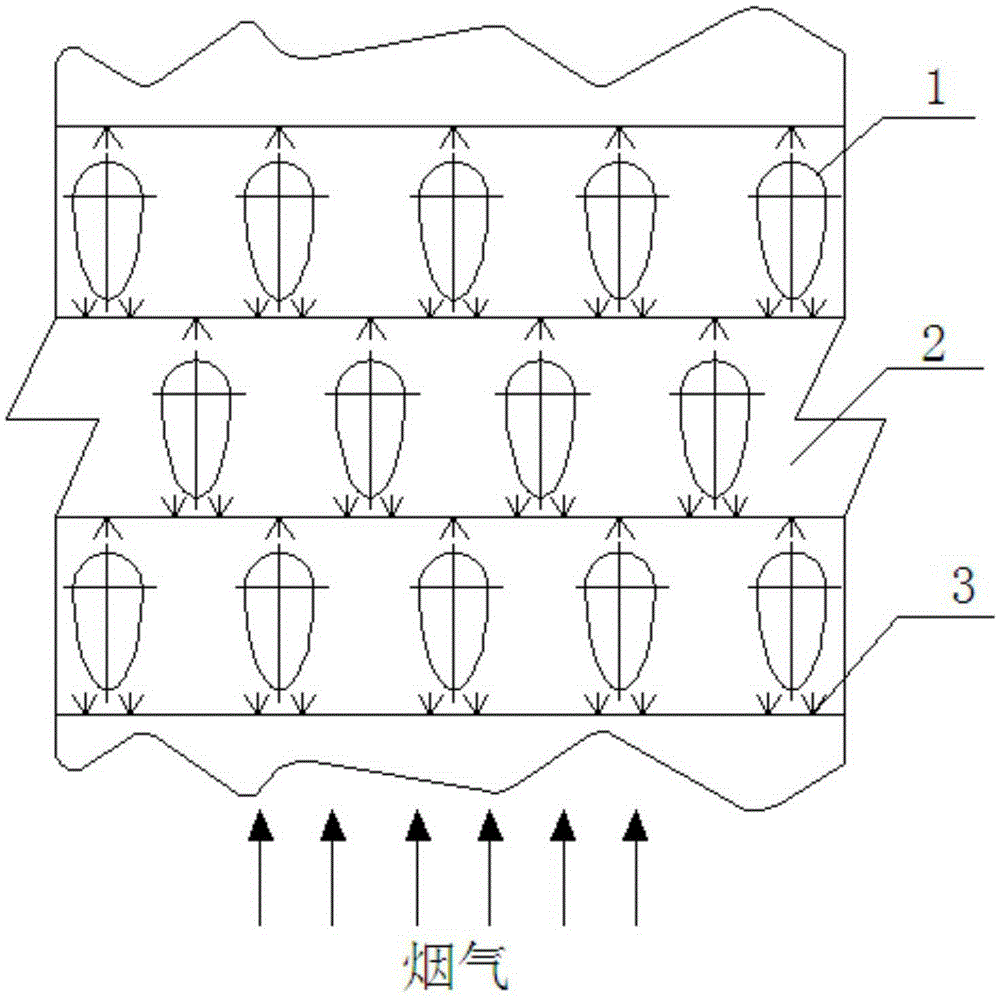

[0029] Such as Figures 1 to 3 shown. The invention discloses a low-resistance forced water-cooled drop-type tube-type demister, which includes a water-cooled drop-type tube bundle demist system arranged on the top of a desulfurization tower, and a forced cooling system for passing cooling water into the water-cooled drop-type tube bundle demist system. water circulatory system;

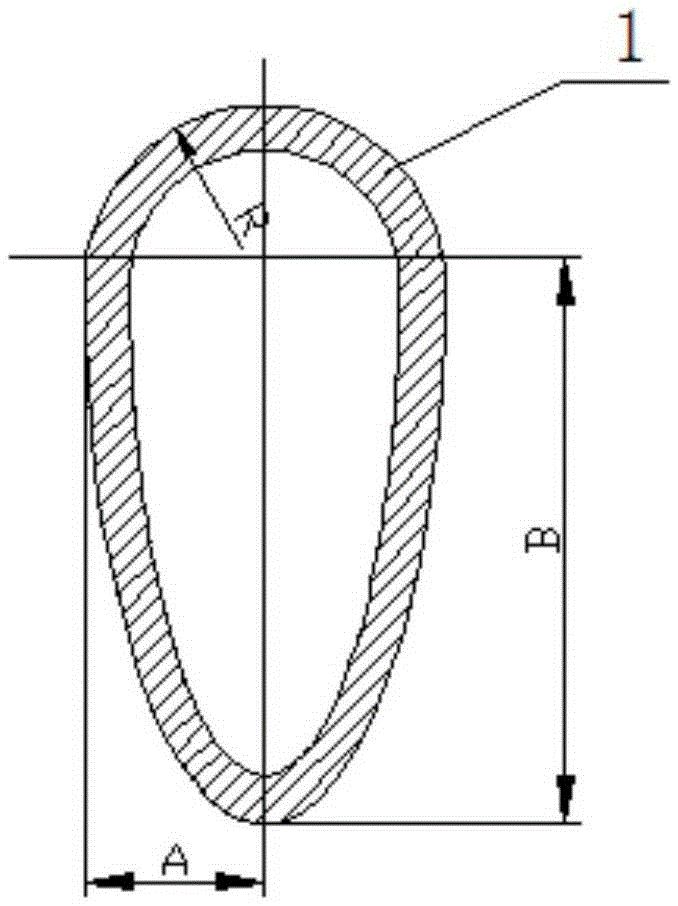

[0030] The water-cooled drop-type tube bundle defogging system is a tube row array composed of tube bundles 1 with drop-shaped cross-sections arranged in a multi-layer dot matrix staggered in the tube box 2;

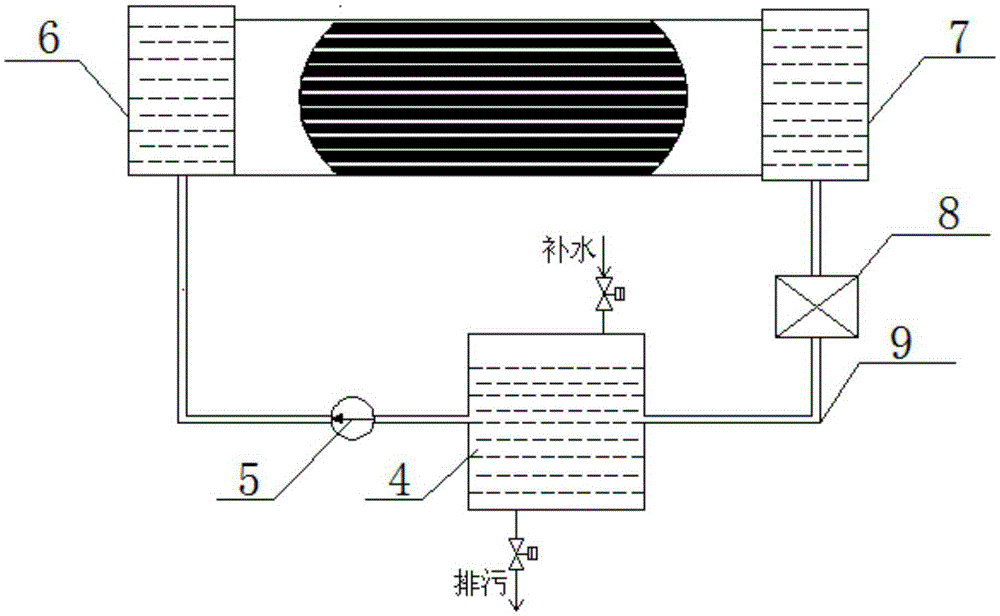

[0031] The forced cooling water circulation system includes a water storage tank 5, a circulation pump 6, a water inlet tank 7, a water outlet tank 8, and an air cooler 9; The pump 6 and the water inlet tank 7; the water inlet end of the pipe row array is connected to the water inlet tank 7, and the water outlet end is connected to the water outlet tank 8.

[0032] The upper part of the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com