Pd/UiO-66-NH2 material having high stability as well as preparation method and application of Pd/UiO-66-NH2 material

A uio-66-nh2 high-stability technology, applied in the direction of separation methods, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of noble metal nanoparticles that are prone to agglomeration, expensive, Inhibit development and other problems, achieve good catalytic effect, long service life, good thermal stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 10

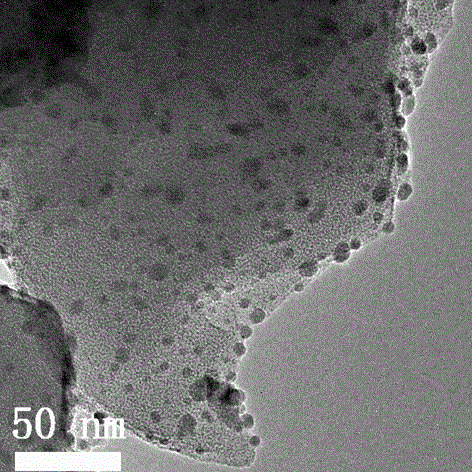

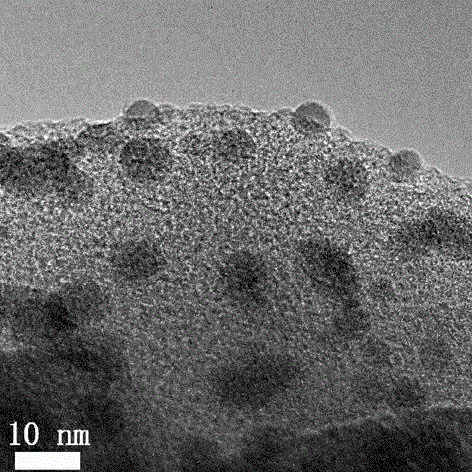

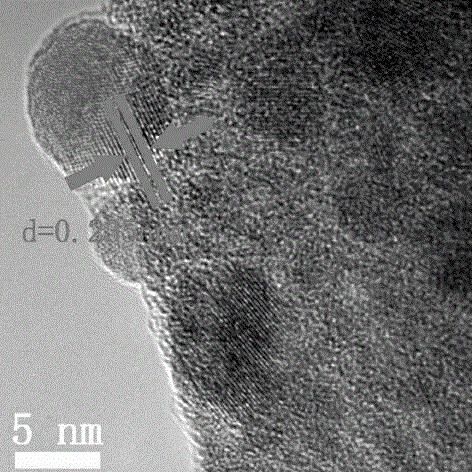

[0033] Embodiment 10.3%Pd / UiO-66-NH 2 preparation of

[0034] 1) UiO-66-NH 2 Preparation: Weigh 0.0706g of 5-aminoterephthalic acid and 0.0261g of zirconium chloride, dissolve them in 5ml of N, N dimethylformamide, conduct a hydrothermal reaction at 120°C for 2880min, filter, wash, and vacuum-dry to obtain UiO- 66-NH 2 ;

[0035] 2) 0.3%Pd / UiO-66-NH 2 Preparation Weigh 0.1g of the UiO-66-NH obtained in Example 1 2 Ultrasonic dissolved in 8ml DMF solution, at the same time, measure 1.12mg of Pd(acac) 2 DMF solution was added dropwise to the above solution, at room temperature, ultrasonicated for 1h, then transferred to a 25ml round bottom flask and stirred for 4h, so that Pd ions could be fully adsorbed and evenly dispersed in UiO-66-NH 2 Carrier surface, freshly prepared NaBH 4 The solution was slowly added dropwise to the above mixed solution, and the Pd 2+ It is reduced to Pd atoms. In this process, it can be seen that the color of the solution changes from yellow to...

Embodiment 20

[0040] Embodiment 20.5%Pd / UiO-66-NH 2 preparation of

[0041] Weigh 0.1gUiO-66-NH 2 Ultrasonic dissolved in 8ml DMF solution, at the same time, measure 1.88mg of Pd(acac) 2 DMF solution was added dropwise to the above solution, and at room temperature, ultrasonicated for 1 hour, then transferred to a 25ml round bottom flask and stirred for 4 hours, so that Pd ions could be fully adsorbed and evenly dispersed on the surface of the carrier. Freshly prepared NaBH 4 The solution was slowly added dropwise to the above mixed solution, and the Pd 2+ It is reduced to Pd atoms. In this process, it can be seen that the color of the solution changes from yellow to black. After half an hour of aging, the Pd 2+ After complete reduction, filter in a sand core funnel, wash the filter cake three times with DMF, and then wash three times with ether to replace the DMF molecules in the MOF pores, dry the filter cake under vacuum at 80°C for 4 hours, 0.5%Pd / UiO-66-NH to get the powder 2 . ...

Embodiment 31

[0043] Example 31.0%Pd / UiO-66-NH 2 preparation of

[0044] Weigh 0.1gUiO-66-NH 2 Ultrasonic dissolved in 8ml DMF solution, at the same time, measure 3.77mg of Pd(acac) 2 DMF solution was added dropwise to the above solution, and at room temperature, ultrasonicated for 1 hour, then transferred to a 25ml round bottom flask and stirred for 4 hours, so that Pd ions could be fully adsorbed and evenly dispersed on the surface of the carrier. Freshly prepared NaBH 4 The solution was slowly added dropwise to the above mixed solution, and the Pd 2+ It is reduced to Pd atoms. In this process, it can be seen that the color of the solution changes from yellow to black. After half an hour of aging, the Pd 2+ After complete reduction, filter in a sand core funnel, wash the filter cake three times with DMF, and then wash three times with ether to replace the DMF molecules in the MOF pores, dry the filter cake under vacuum at 80°C for 4 hours, 1.0%Pd / UiO-66-NH to get the powder 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com