Molten aluminum runner

A technology of aluminum liquid and launder, applied in the field of aluminum processing, which can solve the time-consuming and labor-intensive problems of manual cleaning of alumina and calcium oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

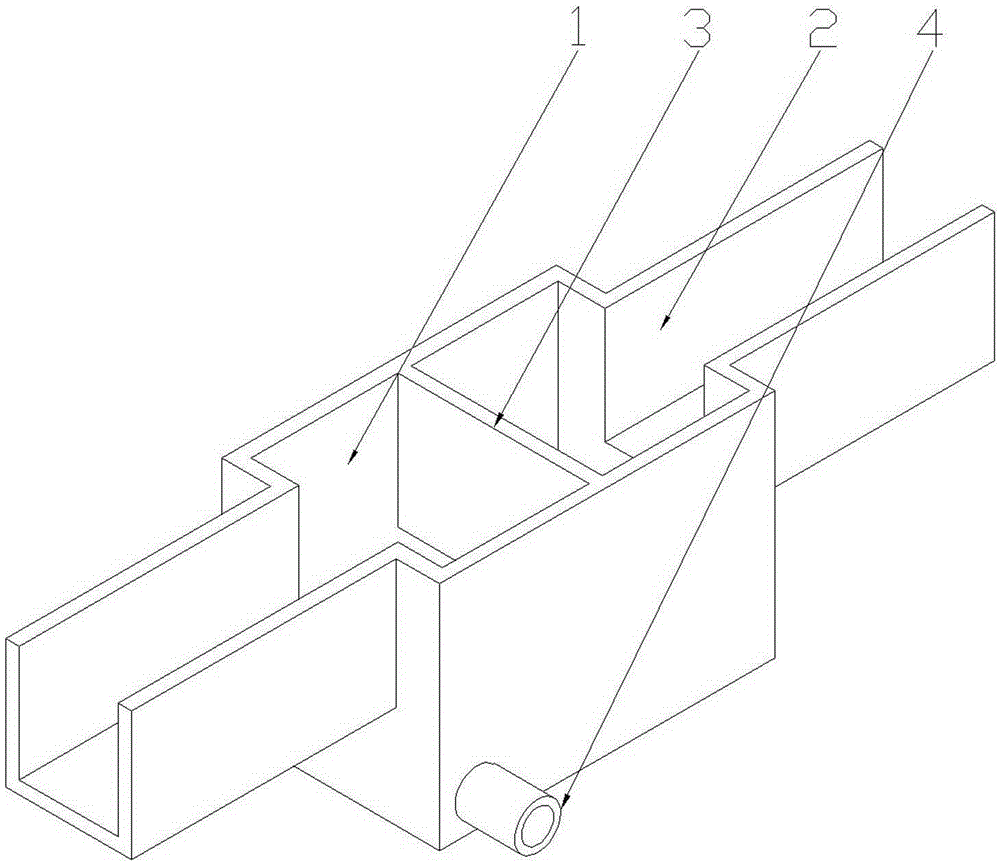

[0015] as attached figure 1 As shown, an aluminum liquid flow tank includes a settling tank 1, the opposite sides of the settling tank 1 are respectively connected with flow channels 2 for the passage of aluminum liquid, the bottom of the settling tank 1 is lower than the bottom of the flow channel 2, and the middle part of the settling tank 1 is set There is a vertically downward baffle 3, the bottom of which is higher than the bottom of the settling tank and lower than the bottom of the flow channel 2, and the lower part of the side wall of the settling tank 1 is provided with an aluminum liquid outflow pipe 4.

[0016] The molten aluminum flowing out of the mixing furnace enters the settling tank 1 through the flow channel 2 on one side of the settling tank 1. Since the middle part of the settling tank 1 is provided with a baffle plate 3, the bottom of the baffle plate 3 is higher than the bottom of the settling tank 1 and lower than the bottom of the flow channel 2. , so t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com