Preparation method of structure with controllable surface hydrophobic property

A high-performance and hydrophobic technology, applied in the photoengraving process of the pattern surface, the process for producing decorative surface effects, and the microstructural technology, which can solve the problem of rarely preparing hydrophobic controllable structures and reduce processing costs. , the effect of reducing difficulty and increasing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Concrete implementation steps of the present invention are as follows:

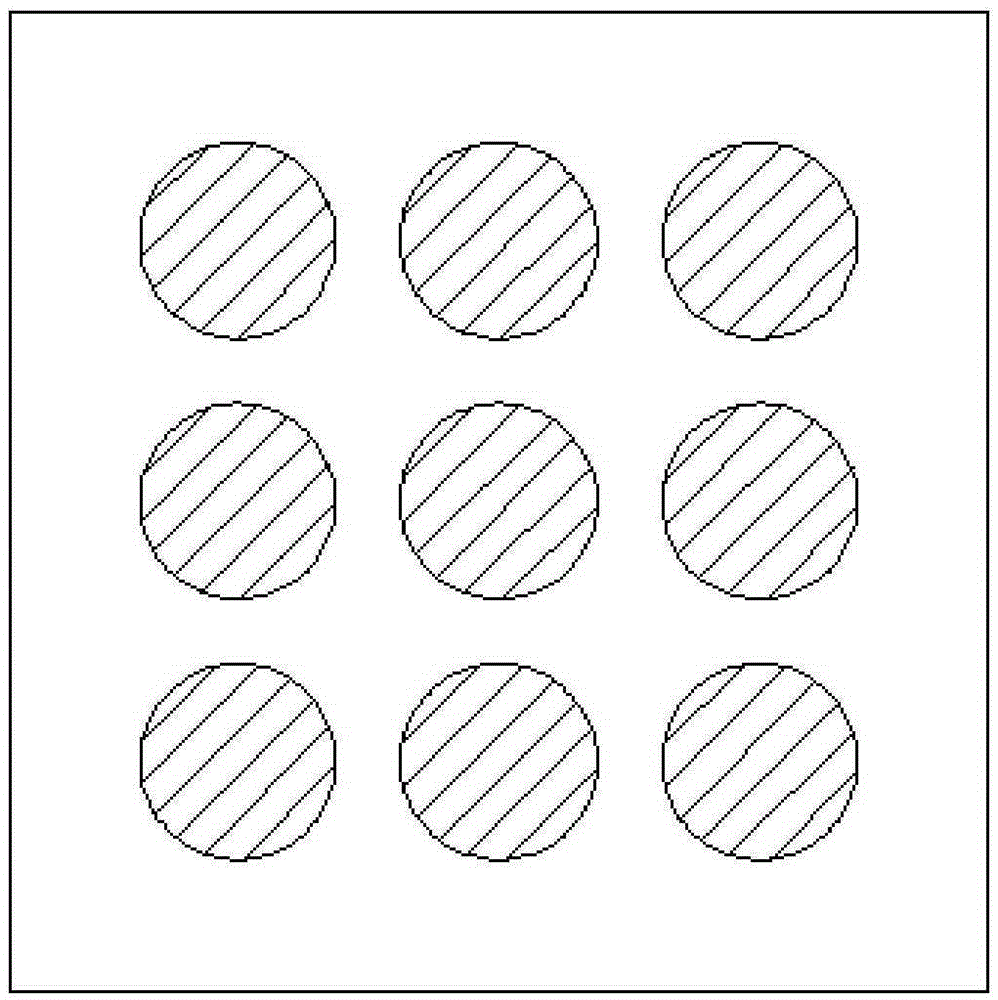

[0039] 1) Spin-coat a layer of SU8-82000 negative photoresist on the silicon substrate with a thickness of 100 μm, and then expose it with a mask plate with a circular light-transmitting array, wherein the mask with a circular light-transmitting array The diameter of the circular hole of the membrane plate is 600 μm, and the distance between two adjacent circular holes is 800 μm. The shape of the mask plate is as follows: figure 1 As shown, the shaded part is a circular light-transmitting area.

[0040] 2) Put the structure obtained after exposure in step 1) into a developing solution for development. After development, the areas that are not exposed to light due to the mask plate are washed away, and finally, a silicon wafer substrate with a cylindrical protrusion array is obtained .

[0041] 3) Spin-coat a layer of polydimethylsiloxane (PDMS) with a curing agent on the silicon wafer substrate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com