Pressureless sintering method for TFT-grade ITO target

A technology of atmospheric pressure sintering and target material, which is applied in the field of atmospheric pressure sintering of TFT-level ITO target materials, which can solve the problems of long production cycle, inability to obtain high-density ITO target materials, and easy delamination of the green body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

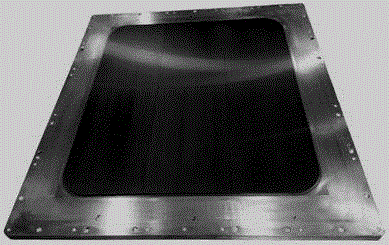

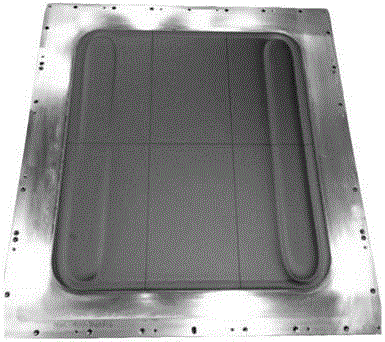

Image

Examples

Embodiment 1

[0023] Weigh 2.7kg of ultra-high activity ITO powder (particle size of powder is 80nm, purity is 99.995%, the highest single impurity component is 10ppm) after adding molding agent and granulated, and put it into a rectangular steel mold with a size of 264mm×347mm. Under the molding pressure of 30MPa, hold the pressure for 15 seconds with a hydraulic press to carry out compression molding. Put the molded blank into a flexible sheath, seal it and put it into a cold isostatic press, hold the pressure for 1200 seconds under a pressure of 180MPa, and perform cold isostatic pressing. Then put the green body formed by cold isostatic pressing into the sintering furnace for sintering. The sintering process is as follows: heat up to 100°C at a heating rate of 0.2°C / min, and hold for 1 hour; then raise the temperature to 250°C at a heating rate of 0.3°C / min, and hold for 4 hours; then raise the temperature at a heating rate of 0.2°C / min to 600°C, hold for 1 hour; then raise the tempera...

Embodiment 2

[0025] Weigh 7kg of ITO powder granulated by adding molding agent (the particle size of the powder is 60nm, the purity is 99.994%, and the single impurity component is up to 15ppm), and put it into a rectangular steel mold with a size of 264mm×850mm. Under the molding pressure of 50MPa, pressurize for 100 seconds with a hydraulic press to carry out compression molding. Put the molded blank into a flexible sheath, seal it and put it into a cold isostatic press, hold the pressure for 600 seconds under a pressure of 240 MPa, and perform cold isostatic pressing. Then put the green body formed by cold isostatic pressing into the sintering furnace for sintering. The sintering process is as follows: raise the temperature to 120 degrees at a heating rate of 0.5 degrees per minute, and keep it for 1.5 hours; then raise the temperature to 300 degrees at a heating rate of 0.6 degrees per minute, and keep it for 8 hours; then raise the temperature at a heating rate of 0.5 degrees per minu...

Embodiment 3

[0028] Weigh 12kg of ITO powder granulated by adding molding agent (the particle size of the powder is 100nm, the purity is 99.995%, and the single impurity component is up to 8ppm), and put it into a rectangular steel mold with a size of 480mm×860mm. Under the molding pressure of 50MPa, the hydraulic press is used to hold the pressure for 300 seconds to carry out compression molding. Put the molded blank into a flexible sheath, seal it and put it into a cold isostatic press, hold the pressure for 300 seconds under a pressure of 300 MPa, and perform cold isostatic pressing. Then put the green body formed by cold isostatic pressing into the sintering furnace for sintering. The sintering process is as follows: raise the temperature to 150 degrees at a heating rate of 1 degree / minute, and keep it for 2 hours; then raise the temperature to 350 degrees at a heating rate of 0.9 degrees / minute, and keep it for 10 hours; then raise the temperature at a heating rate of 0.9 degrees / minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com