Gasoline octane value booster and preparation method thereof

A gasoline octane number and accelerator technology, which is applied in the field of gasoline octane number accelerator and its preparation, can solve the problems of ash content increase, residue, three-way catalytic system poisoning, etc., achieve a large increase in octane number, and produce raw materials Easy to get, non-toxic product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the present invention, the gasoline octane booster is prepared by the following method: a certain mass part of the active component is dissolved in the mass part of the solvent, a catalyst is added, and the reaction is carried out at a temperature of 120° C. to 130° C. for 2 hours to 1 hour. 3h, the product is obtained, the catalyst is separated, and the product is cooled to 60°C ~ 75°C, and an antioxidant is added; the clean dispersant and synergistic stabilizer are added to the co-solvent, and then added to the cooled product, and the circulation is stirred 0.5h ~ 2h prepared. Adopted in the present invention is Cu / Zn / Al

[0022] base catalyst.

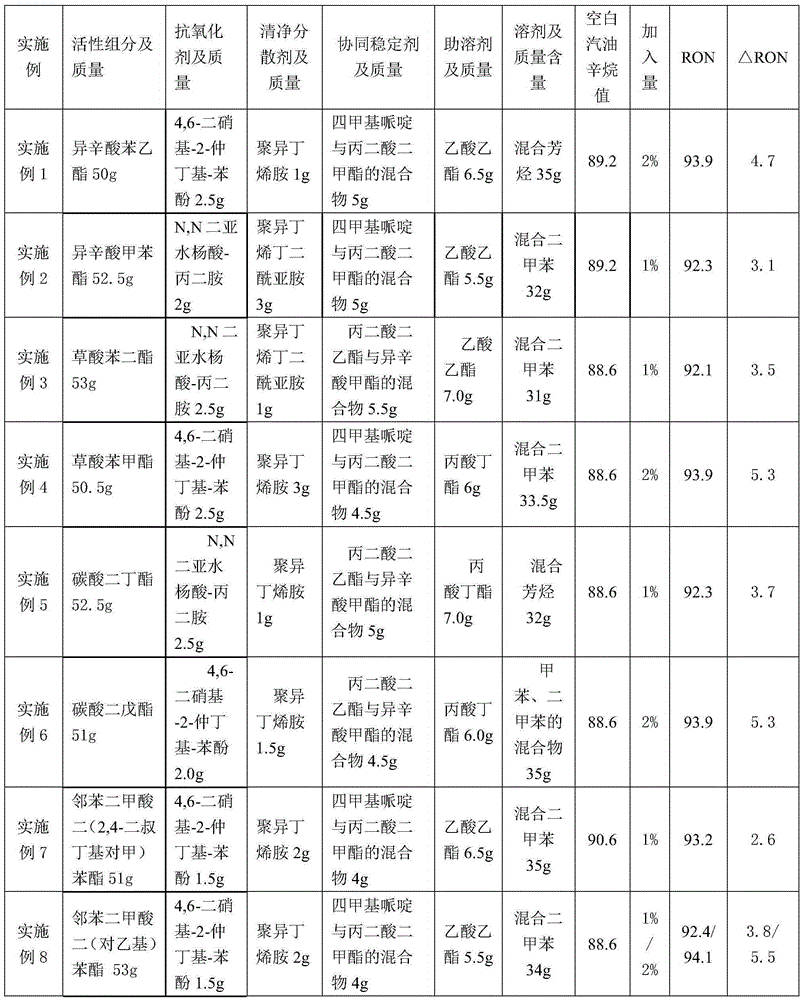

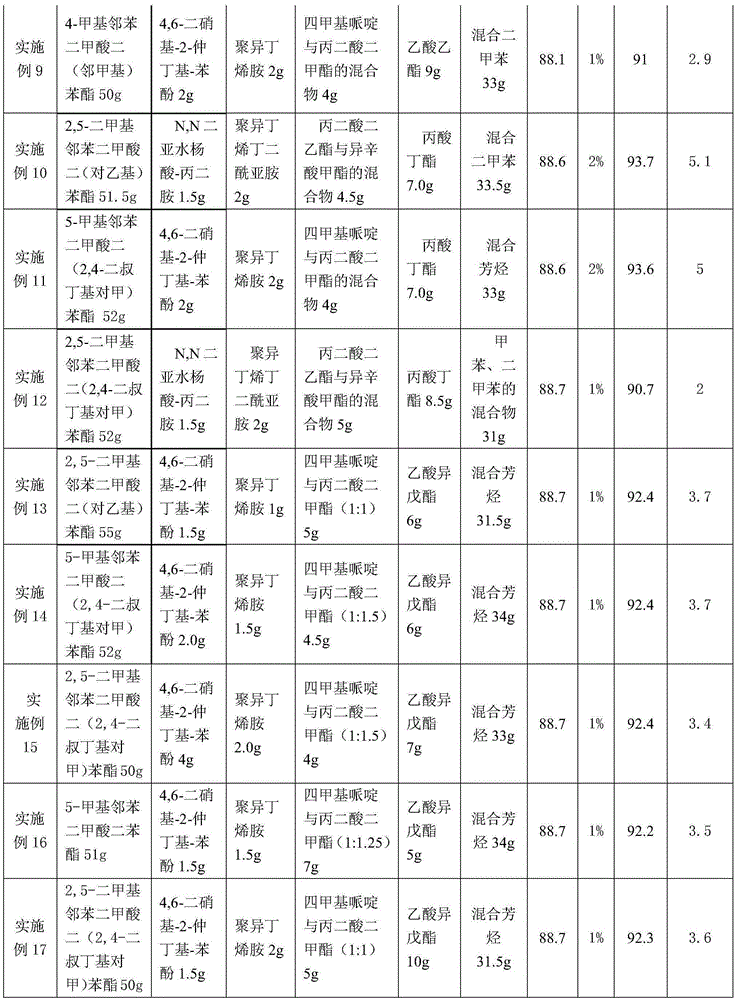

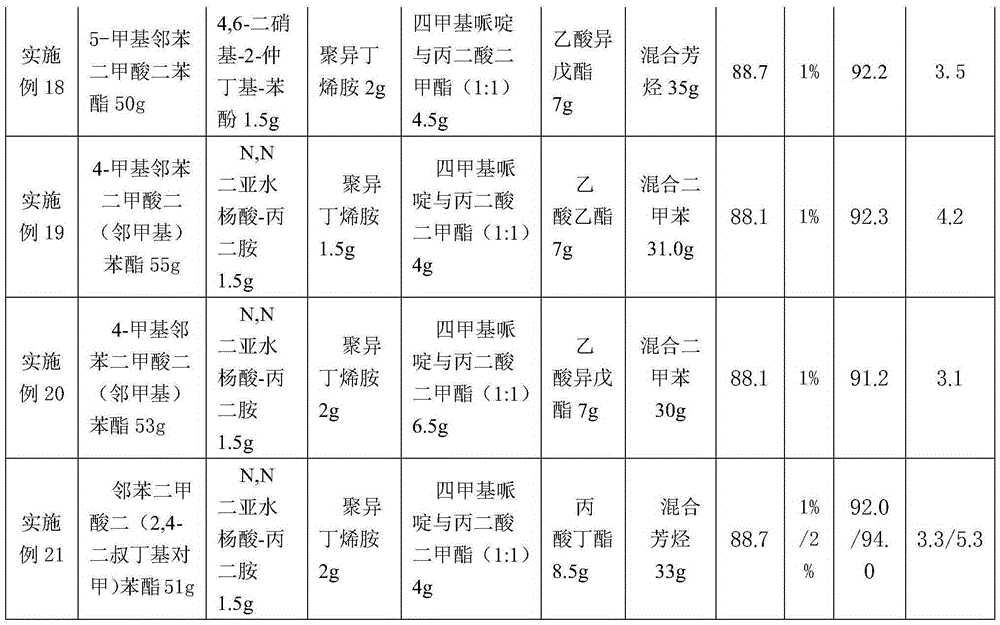

[0023] Table 1 Gasoline octane booster with different components

[0024]

[0025]

[0026]

[0027] The physical and chemical properties of the gasoline octane number booster prepared by the method of the present invention are as shown in table 2:

[0028] Table 2 Physicochemical properties of gasoline octane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com