A kind of preparation method of leather fatliquor

A leather fatliquor, animal and vegetable oil technology, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. The problems of complex process, acid and salt-containing wastewater discharge, etc., to achieve the effect of low three waste discharge, simplified process, good quality stability and fatliquoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The heated lard is pumped into the membrane sulfonator at a flow rate of 4kg / h with a metering pump, and sulfur trioxide gas with a concentration of 4% is introduced at the same time, and circulating water is connected to the jacket of the sulfonator. The fixed water temperature is 65°C. After the neutralization value is stable, a certain amount of sulfonic acid ester is received, the temperature is controlled at 60°C, chlorine gas is introduced, and the flow rate of chlorine gas is adjusted, and the density of the product after chlorination is controlled to be 1.1 times that before chlorination. After the chlorination reaction is completed, about 600 g of chlorinated lard sulfonate is neutralized with 32% liquid alkali to pH 9.3, hydrogen peroxide is added for decolorization, and water is added to adjust the solid content to obtain a leather fatliquor product.

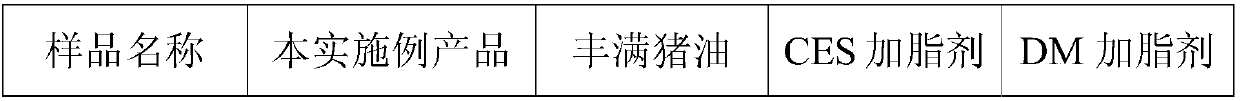

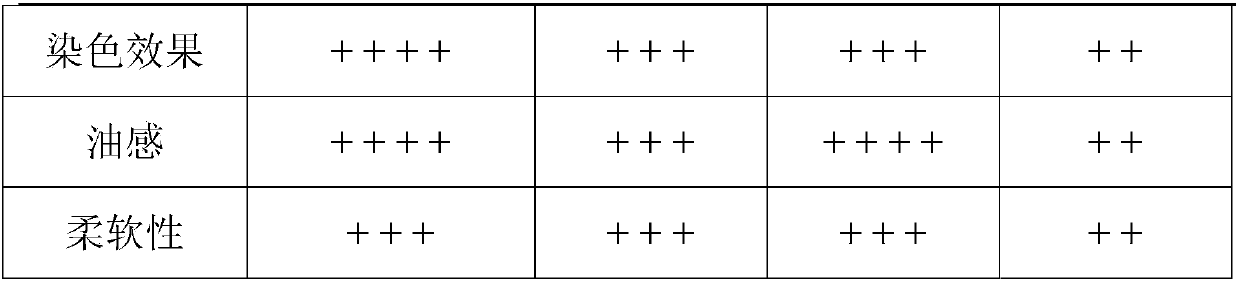

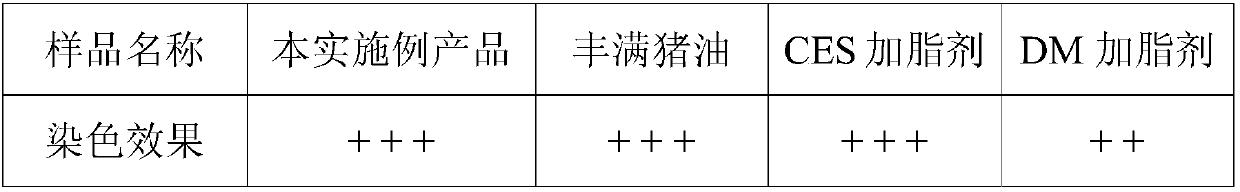

[0022] This example product SO 3 The binding rate is 4.9%, the chlorine content is 13.5%, and it shows good...

Embodiment 2

[0027] The heated tallow was pumped into the membrane sulfonator at a flow rate of 5kg / h with a metering pump, and sulfur trioxide gas with a concentration of 6% was introduced at the same time, and circulating water was connected to the jacket of the sulfonator. The fixed water temperature is 70°C. After the neutralization value was stable, a certain amount of sulfonic acid ester was received, the temperature was controlled to 70°C, chlorine gas was introduced, and the flow rate of chlorine gas was adjusted, and the density of the product after chlorination was controlled to be 1.1 times that before chlorination. After the chlorination reaction is completed, about 800 g of chlorinated tallow sulfonate is neutralized to pH 8.7 with diethanolamine, hydrogen peroxide is added for decolorization, and water is added to adjust the solid content to obtain a leather fatliquor product.

[0028] This example product SO 3 The binding rate is 6.7%, the chlorine content is 15.4%, and it ...

Embodiment 3

[0032] Mix the heated lard and suet oil with a mass ratio of 1:1, and pump the mixed oil into the membrane sulfonator at a flow rate of 6.5kg / h with a metering pump, and at the same time, introduce sulfur trioxide gas with a concentration of 7%. , and connect the circulating water in the jacket of the sulfonator, and set the water temperature to 75 ℃. After the neutralization value is stable, a certain amount of sulfonic acid ester is received, the temperature is controlled at 65°C, chlorine gas is introduced, and the flow rate of chlorine gas is adjusted, and the density of the product after chlorination is controlled to be 1.2 times that before chlorination. After the chlorination reaction is completed, about 850 g of the chlorinated mixed oil sulfonate is neutralized with 32% liquid alkali to pH 8.9, hydrogen peroxide is added for decolorization, and water is added to adjust the solid content to obtain a leather fatliquor product.

[0033] This example product SO 3 The bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com